Abstract

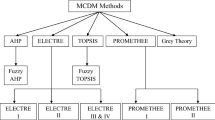

The decision for facility location selection is an important one in the context of management of Supply Chain (SC). Facility location decision affects the overall SC performance, since there is an influence on the cost, delivery speed, service levels and effectiveness of SC. Hence it is essential to evaluate the impact of selection of each facility location. In addition to the traditional criteria such as market, labor, transportation, community and climate, Quality of Life (QOL) has also become an important factor for sustainable facility location selection decision. Since QOL includes aspects of social, economic, environmental, and psychological well-being therefore quantification of QOL for facility location evaluation is a challenging task. Due to subjectivity of the decision makers, vagueness sets in the decision making process and hence fuzzy decision making approach is required for handling the vagueness in assessment of QOL factor. Thus the present study considers an effective integrated approach using Fuzzy Analytical Hierarchy Process (FAHP) and Fuzzy Technique for Order Performance by Similarity to Ideal Solution (FTOPSIS) for evaluation of facility locations, considering the criteria of QOL. FAHP is used for calculating the weight of each QOL criterion and FTOPSIS methodology is used for computing the rank of the facility location options under the fuzzy environment. The application of this integrated approach is applied to case of an Indian manufacturing company.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Kalantari, A.H.: Facility location selection for global manufacturing. https://dc.uwm.edu/cgi/viewcontent.cgi?referer=https://scholar.google.co.in/&httpsredir=1&article=1238&context=etd. Accessed 29 Nov 2018

Chu, T.-C.: Facility location selection using fuzzy TOPSIS under group decisions. Int. J. Uncertain. Fuzziness Knowl. Based Syst. 10(6), 687–701(2002)

Feneri, A.M., Vagiona, D., Karanikolas, N.: Multi-criteria decision making to measure quality of life: an integrated approach for implementation in the urban area of Thessaloniki, Greece. Appl. Res. Qual. Life 10(4), 573–587 (2015)

World commission on Environment and Development: Report of the world commission on environment and development: our common future. http://www.un-documents.net/our-common-future.pdf. Accessed 29 Nov 2018

Lambiri, D., Biagi, B., Royuela, V.: Quality of life in the economic and urban economic literature. Soc. Indic. Res. 84(1), 1–25 (2007)

Christodoulou, P., Fleet, D., Hanson, P., Phaal, R., Probert, D., Shi, Y.: Making the right things in the right places: a structured approach to developing and exploiting manufacturing footprint strategy. Institute for Manufacturing, University of Cambridge, Cambridge, UK (2007)

Oshri, I.: Offshoring Strategies: Evolving Captive Center Models. MIT Press, Cambridge, Massachusetts. https://mitpress.mit.edu/books/offshoring-strategies (2011)

Chadawada, R., Sarfaraz, A., Jenab, K., Pourmohammadi, H.: Integration of AHP-QFD for selecting facility location. Benchmarking Int. J. 22(3), 411–425 (2015)

Tesfazghi, E.S., Martinez, J.A., Verplanke, J.J.: Variability of quality of life at small scales: Addis Ababa, Kirkos Sub-City. Soc. Indic. Res. 98(1), 73–88 (2010)

Das, D.: Urban quality of life: a case study of Guwahati. Soc. Indic. Res. 88(2), 297–310 (2008)

Marans, R.W.: Quality of urban life studies: an overview and implications for environment-behaviour research. Procedia Soc. Behav. Sci. 35, 9–22 (2012)

Darbari, J.D., Agarwal, V., Yadavalli, V.S., Galar, D., Jha, P.C.: A multi-objective fuzzy mathematical approach for sustainable reverse supply chain configuration. J. Transp. Supply Chain Manag. 11(1), 1–12 (2017)

Farahani, R.Z., Asgari, N.: Combination of MCDM and covering techniques in a hierarchical model for facility location: a case study. Eur. J. Oper. Res. 176(3), 1839–1858 (2007)

Farahani, R.Z., SteadieSeifi, M., Asgari, N.: Multiple criteria facility location problems: a survey. Appl. Math. Model. 34(7), 1689–1709 (2010)

Shukla, R.K., Garg, D., Agarwal, A.: An integrated approach of Fuzzy AHP and Fuzzy TOPSIS in modeling supply chain coordination. Prod. Manuf. Res. 2(1), 415–437 (2014)

Kishore, P., Padmanabhan, G.: An integrated approach of fuzzy AHP and fuzzy TOPSIS to select logistics service provider. J. Manuf. Sci. Prod. 16, 51–59 (2016)

Ayhan, M.B.: A fuzzy AHP approach for supplier selection problem: a case study in a Gear motor company. arXiv preprint arXiv:1311.2886 (2013)

Nazam, M., Xu, J., Tao, Z., Ahmad, J., Hashim, M.: A fuzzy AHP-TOPSIS framework for the risk assessment of green supply chain implementation in the textile industry. Int. J. Supply Oper. Manag. 2(1), 548 (2015)

Saaty, T.L.: The Analytic Hierarchy Process, vol. 137. New York (1980)

Chou, S.W., Chang, Y.C.: The implementation factors that influence the ERP (enterprise resource planning) benefits. Decis. Support Syst. 46(1), 149–157 (2008)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Aditi, Kaul, A., Darbari, J.D., Jha, P.C. (2020). A Fuzzy MCDM Model for Facility Location Evaluation Based on Quality of Life. In: Das, K., Bansal, J., Deep, K., Nagar, A., Pathipooranam, P., Naidu, R. (eds) Soft Computing for Problem Solving. Advances in Intelligent Systems and Computing, vol 1048. Springer, Singapore. https://doi.org/10.1007/978-981-15-0035-0_56

Download citation

DOI: https://doi.org/10.1007/978-981-15-0035-0_56

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-15-0034-3

Online ISBN: 978-981-15-0035-0

eBook Packages: Intelligent Technologies and RoboticsIntelligent Technologies and Robotics (R0)