Abstract

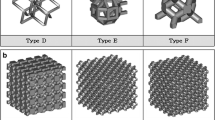

Several implant materials are used in cranial surgery. Still, each one has its drawbacks, such as the risk of infections, low mechanical strength, or low osseointegration. Implants with a porous surface are considered more effective than a smooth and rough coating. The porosity density and structure also influence the mechanical properties of the final implant. Moreover, the implant properties depend on the manufacturing method.

This study aims to present a custom-made cranial scaffold composed of two distinct layers. A compact inner one guarantees adequate structural properties to the scaffold. In contrast, a porous outer one lightens the scaffold structure and assures the correct osseointegration. The customized scaffold has been designed through a 3D free-form modeling system. It can be manufactured by 3D printing techniques such as direct metal laser sintering in titanium or via selective laser sintering using PEEK. The advantages and limitations of the multi-layered custom-made scaffold and the related design process are qualitatively described.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Khaja, M., Saied, D., Abdulrahman, A.A., Sherif, E., Ashfaq, M., Wadea, A.: Structural and mechanical characterization of custom design cranial implant created using additive manufacturing. Electron. J. Biotechnol. 29, 22–31 (2017). https://doi.org/10.1016/j.ejbt.2017.06.005

Parthasarathy, J.: 3D modeling, custom implants and its future perspectives in craniofacial surgery. Ann. Maxillofac. Surg. 4(1), 9–18 (2014). https://doi.org/10.4103/2231-0746.133065

Mandolini, M., Brunzini, A., Germani, M., Manieri, S., Mazzoli, A., Pagnoni, M.: Selective laser sintered mould for orbital cavity reconstruction. Rapid Prototyping J. 25(1), 95–103 (2019). https://doi.org/10.1108/RPJ-05-2017-0098

Cho, H.R., Roh, T.S., Shim, K.W., Kim, Y.O., Lew, D.H., Yun, I.S.: Skull reconstruction with custom made three-dimensional titanium implant. Arch. Craniofac. Surg. 16(1), 11–16 (2015). https://doi.org/10.7181/acfs.2015.16.1.11

Mandolini, M., Brunzini, A., Serrani, E.B., Pagnoni, M., Mazzoli, A., Germani, M.: Design of a custom-made cranial implant in patients suffering from Apert syndrome. In: Proceedings of the 22nd International Conference on Engineering Design (ICED19), Delft, The Netherlands, 5–8 August 2019. https://doi.org/10.1017/dsi.2019.75

Brunzini, A., et al.: Orbital wall reconstruction by selective laser sintered mould. In: Proceedings of the lASTED International Conference Biomedical Engineering (BioMed 2017), 20–21 February 2017. Innsbruck, Austria (2017). https://doi.org/10.2316/P.2017.852-045

Kwarcinski, J., Boughton, P., Ruys, A., Doolan, A., van Gelder, J.: Cranioplasty and craniofacial reconstruction: a review of implant material, manufacturing method and infection risk. Appl. Sci. 7, 1–17 (2017). https://doi.org/10.3390/app7030276

Mandolini, M., Caragiuli, M., Brunzini, A., Mazzoli, A., Pagnoni, M.: A procedure for designing custom-made implants for forehead augmentation in people suffering from apert syndrome. J. Med. Syst. 44(9), 1 (2020). https://doi.org/10.1007/s10916-020-01611-9

Zanotti, B., et al.: Surgical pitfalls with custom made porous hydroxyapatite cranial implants. Plast. Aesthetic Res. 2(1), 7–11 (2015). https://doi.org/10.4103/2347-9264.149364

Saptaji, K., Gebremariam, M.A., Azhari, M.A.B.M.: Machining of biocompatible materials: a review. Int. J. Adv. Manufact. Technol. 97(5–8), 2255–2292 (2018). https://doi.org/10.1007/s00170-018-1973-2

Otsuki, B., Takemoto, M., Fujibayashi, S., Neo, M., Kokubo, T., Nakamura, T.: Pore throat size and connectivity determine bone and tissue ingrowth into porous implants: three dimensional micro-CT based structural analyses of porous bioactive titanium implants. Biomaterials 27, 5892–5900 (2006). https://doi.org/10.1016/j.biomaterials.2006.08.013

Masood, S.H., Singh, J.P., Morsi, Y.: The design and manufacturing of porous scaffolds for tissue engineering using rapid prototyping. Int. J. Adv. Manufact. Technol. 27, 415–420 (2005). https://doi.org/10.1007/s00170-004-2187-3

Zhao, B., Gain, A.K., Ding, W., Zhang, L., Li, X., Fu, Y.: A review on metallic porous materials: pore formation, mechanical properties, and their applications. Int. J. Adv. Manufact. Technol. 95(5–8), 2641–2659 (2017). https://doi.org/10.1007/s00170-017-1415-6

Shuai, C., Yang, B., Peng, S., Li, Z.: Development of composite porous scaffolds based on poly(lactide-co-glycolide)/nano-hydroxyapatite via selective laser sintering. Int. J. Adv. Manufact. Technol. 69(1–4), 51–57 (2013). https://doi.org/10.1007/s00170-013-5001-2

Vlasea, M., Shanjani, Y., Bothe, A., Kandel, R., Toyserkani, E.: A combined additive manufacturing and micro-syringe deposition technique for realization of bio-ceramic structures with micro-scale channels. Int. J. Adv. Manufact. Technol. 68(9–12), 2261–2269 (2013). https://doi.org/10.1007/s00170-013-4839-7

Armillotta, A., Pelzer, R.: Modeling of porous structures for rapid prototyping of tissue engineering scaffolds. Int. J. Adv. Manufact. Technol. 39, 501–511 (2008). https://doi.org/10.1007/s00170-007-1247-x

Basalah, A., Esmaeili, S., Toyserkani, E.: Mechanical properties of additive-manufactured porous titanium bio-structures with oriented macro-scale channels. Int. J. Adv. Manufact. Technol. 84(9–12), 2239–2246 (2015). https://doi.org/10.1007/s00170-015-7849-9

Murphy, C.M., Haugh, M.G., O’Brien, F.J.: The effect of mean pore size on cell attachment, proliferation and migrationin collagen–glycosaminoglycan scaffolds for bone tissue engineering. Biomaterials 31, 461–466 (2010). https://doi.org/10.1016/j.biomaterials.2009.09.063

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Mazzoli, A., Mandolini, M., Brunzini, A., Caragiuli, M., Germani, M. (2022). Preliminary Considerations on the Design of Multi-layered Bone Scaffold for Laser-Based Printing. In: Su, R., Zhang, YD., Liu, H. (eds) Proceedings of 2021 International Conference on Medical Imaging and Computer-Aided Diagnosis (MICAD 2021). MICAD 2021. Lecture Notes in Electrical Engineering, vol 784. Springer, Singapore. https://doi.org/10.1007/978-981-16-3880-0_21

Download citation

DOI: https://doi.org/10.1007/978-981-16-3880-0_21

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-3879-4

Online ISBN: 978-981-16-3880-0

eBook Packages: EngineeringEngineering (R0)