Abstract

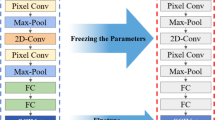

Heavy worn tools can cause severe cutting vibrations, leading to a decrease in the surface quality of the workpiece. It is important to monitor tool states and replace the worn tool in time. The traditional tool wear states monitoring methods are mainly based on machine learning and features engineering for the specific cutting condition. In this paper, a novel tool wear states monitoring method is proposed for the multi working conditions monitoring task. The similarity of tools wear process is used to realize the transformation of the priori knowledge from the labeled source domain to the unlabeled target domain. An unsupervised deep transfer learning model is built for the tools wear states recognition, based on neural networks. The network is composed of one-dimensional (1D) convolutional neural network (CNN) and multi-layer perceptron (MLP). There is a domain adaptation unit in the penultimate layer to achieve the deep features alignment. Our experiments demonstrate that the proposed model can achieve a classification accuracy of higher than 80% in the target domain.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Stavropoulos, P., Papacharalampopoulos, A., Vasiliadis, E., Chryssolouris, G.: Tool wear predictability estimation in milling based on multi-sensorial data. Int. J. Adv. Manuf. Technol. 82(1–4), 509–521 (2016)

Liao, X.P., Zhou, G., Zhang, Z.K., Lu, J., Ma, J.Y.: Tool wear state recognition based on GWO-SVM with feature selection of genetic algorithm. Int. J. Adv. Manuf. Technol. 104(1–4), 1051–1063 (2019)

Chen, N., Hao, B.J., Guo, Y.L., Li, L., Khan, M.A., He, N.: Research on tool wear monitoring in drilling process based on APSO-LS-SVM approach. Int. J. Adv. Manuf. Technol. 108(7–8), 2091–2101 (2020)

Li, X.B., et al.: A data-driven approach for tool wear recognition and quantitative prediction based on radar map feature fusion. Measurement 185 (2021)

Bazi, R., Benkedjouh, T., Habbouche, H., Rechak, S., Zerhouni, N.: A hybrid CNN-BiLSTM approach-based variational mode decomposition for tool wear monitoring. Int. J. Adv. Manuf. Technol. 119(5–6), 3803–3817 (2022)

Li, Z.M., Zhong, W., Shi, Y.G., Yu, M., Zhao, J., Wang, G.F.: Unsupervised tool wear monitoring in the corner milling of a titanium alloy based on a cutting condition-independent method. Machines 10(8) (2022)

Pan, T.H., Zhang, J., Zhang, X., Zhao, W.H., Zhang, H.J., Lu, B.H.: Milling force coefficients-based tool wear monitoring for variable parameter milling. Int. J. Adv. Manuf. Technol. 120(7–8), 4565–4580 (2022)

Feuz, K.D., Cook, D.J.: Transfer learning across feature-rich heterogeneous feature spaces via feature-space remapping (FSR). ACM Trans. Intell. Syst. Technol. 6(1) (2015)

Jiang, S.Y., et al.: Multi-label metric transfer learning jointly considering instance space and label space distribution divergence. IEEE Access 7, 10362–10373 (2019)

Liao, Y.X., Huang, R.Y., Li, J.P., Chen, Z.Y., Li, W.H.: Dynamic distribution adaptation based transfer network for cross domain bearing fault diagnosis. Chin. J. Mech. Eng. 34(1), 52 (2021)

Li, C., Zhang, S.H., Qin, Y., Estupinan, E.: A systematic review of deep transfer learning for machinery fault diagnosis. Neurocomputing 407, 121–135 (2020)

Lee, K., et al.: Multi-objective instance weighting-based deep transfer learning network for intelligent fault diagnosis. Appl. Sci.-Basel 11(5) (2021)

Li, J.B., Lu, J., Chen, C.Y., Ma, J.Y., Liao, X.P.: Tool wear state prediction based on feature-based transfer learning. Int. J. Adv. Manuf. Technol. 113(11–12), 3283–3301 (2021)

Zhu, Y.M., Zi, Y.Y., Xu, J., Li, J.: An unsupervised dual-regression domain adversarial adaption network for tool wear prediction in multi-working conditions. Measurement 200 (2022)

Lu, N.N., Wang, S.C., Xiao, H.H.: An unsupervised intelligent fault diagnosis system based on feature transfer. Math. Probl. Eng. 2021 (2021)

Borgwardt, K.M., Gretton, A., Rasch, M.J., Kriegel, H.P., Scholkopf, B., Smola, A.J.: Integrating structured biological data by kernel maximum mean discrepancy. Bioinformatics 22(14), E49–E57 (2006)

Li, K., Chen, M.S., Lin, Y.C., Li, Z., Jia, X.S., Li, B.: A novel adversarial domain adaptation transfer learning method for tool wear state prediction. Knowl.-Based Syst. 254 (2022)

Bahador, A., Du, C.L., Ng, H.P., Dzulqarnain, N.A., Ho, C.L.: Cost-effective classification of tool wear with transfer learning based on tool vibration for hard turning processes. Measurement 201 (2022)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Lan, Q., Chen, B., Yao, B., He, W. (2023). Unsupervised Deep Transfer Learning Model for Tool Wear States Recognition. In: Zhang, H., et al. International Conference on Neural Computing for Advanced Applications. NCAA 2023. Communications in Computer and Information Science, vol 1870. Springer, Singapore. https://doi.org/10.1007/978-981-99-5847-4_20

Download citation

DOI: https://doi.org/10.1007/978-981-99-5847-4_20

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-99-5846-7

Online ISBN: 978-981-99-5847-4

eBook Packages: Computer ScienceComputer Science (R0)