Abstract

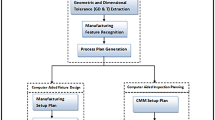

In this paper, a methodology to perform fixture design as an integrated aspect of process planning is proposed. A three-phase methodology for the fixture design activity has been developed. The three phases include predesign analysis (phase I), functional analysis (phase II), and productivity improvement (phase III). In phase I, the product design information is studied, and initial fixture design aspects are developed. In phase II, the clamping and location aspects of fixture design are addressed for the given initial process sequence and product design information. Phase III involves studying ways to increase the productivity including using simultaneous machining approaches, multiclustering, use of specialized jigs, etc.

Similar content being viewed by others

References

Bidanda, B. and Cohen, P. H. (1990) Development of a computer aided fixture selection system for concentric rotational parts, in Advances in Integrated Design and Manufacturing, DE-Vol. 23-1, Proceedings of 1990 ASME Winter Annual Meeting, San Francisco, CA, ASME, New York, pp. 151–162.

Boerma, J. and Kals, H. (1988) FIXES: a system for automatic selection of set-ups and design of fixtures. CIRP Annals, 37 (1), 443–446.

Cecil, J. A. (1993) An integrated methodology for fixture design, Independent Study Research Report, Knowledge Based Systems Lab, Department of Industrial Engineering, Texas A&M University.

Chang, T. C. (1990) Expert Process Planning for Manufacturing, Addison-Wesley Publishing Company, Reading, MA.

Chang, T. C., Wysk, R. A. and Wang, H. P. (1991) Computer-Aided Manufacturing, Prentice-Hall Inc., Englewood Cliffs, NJ.

Chang, C.-H. (1992) Computer assisted fixture planning for machining processes. Manufacturing Review, 5 (1), 15–28.

Chou, Y. C., Chandru, V. and Barash, M. M. (1989) A mathematical approach to automatic configuration of machining fixtures: analysis and synthesis. ASME Transactions, Journal of Engineering for Industry, 111 (4), 299–306.

Dong, X., Gilman, C. and Wozny, M. (1994) Feature-based fixture design and set-up planning, in Artificial Intelligence in Optimal Design and Manufacturing, Prentice-Hall Inc., Englewood Cliffs, NJ.

Ferreira, P. M. and Liu, C. R. (1988) Generation of workpiece orientations for machining using a rule based system. Robotics and Computer Integrated Manufacturing, 4 (3/4), 545–555.

Gandhi, M. V. and Thompson, B. S. (1987) Automated design of modular fixtures for flexible manufacturing systems. Journal of Manufacturing Systems, 5 (4), 243–252.

Hari, U. (1993) Plan generation strategies for a knowledge based automated process planning system, Master's Thesis, Department of Industrial Engineering, Texas A&M University.

Ingrand, F. and Latombe, J. (1980) Functional Reasoning for Automatic Fixture Design, Lifia-IMAG, Grenoble, France.

Mani, M. and Wilson, W. R. D. (1988) Automated design of workholding fixtures using kinematic constraints synthesis, in Proceedings of the Thirteenth NAMRC, pp. 427–432. Society for Manufacturing Engineering, Dearborn, MI.

Markus, A. et al. (1984) Fixture design using PROLOG: an expert system. Robotics and Computer Integrated Manufacturing, 1 (2), 195–201.

Mayer, R., Su, C-J., Yen, J. and Hari, U. (1993) Plan generation strategies for a knowledge based automated process planning system, Working Paper, Knowledge Based Systems Lab, Department of Industrial Engineering, Texas A&M University, September.

Menassa, R. J. and DeVries, W. R. (1989) Locating point synthesis in fixture design. CIRP Annals, 38 (1), 165–170.

Miller, A. S. and Hannam, R. G. (1985) Computer aided design using a knowledge base approach and its application to the design of jigs and fixtures. Proceedings - Institute of Mechanical Engineering, 199 (B4), 227–234.

Nee, A. Y. C., Bhattacharya, N. and Poo, A. N. (1987) Applying AI in jigs and fixture design. Robotics and Computer Integrated Manufacturing, 3 (2), 195–201.

Nee, A. Y. C., Prombanpong, S. and Senthil Kumar, A. (1991) A state of the art review of flexible and computerized fixture design systems, in Proceedings 5th International Manufacturing Conference, Singapore, April, pp. B206–B212.

Pham, D. T., Nategh, M. J. and De Sam Lazaro, A. (1989) Jig and fixture designer's assistant. International Journal of Advanced Manufacturing Technology, 4, 26–45.

Sakurai, H. (1990) Automatic setup planning and fixture design for machining. Journal of Manufacturing Systems, 11 (1), 30–37.

Shawki, G. S. A. (1967) Rigidity considerations in fixture design - contact rigidity for eccentric clampings. International Journal of Machine Tool Design and Research, 7, 195–209.

Wilensky, R. (1983) Planning and Understanding: A Computational Approach to Human Reasoning, Addison-Wesley Publishing Company, Reading, MA.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Cecil, J., Mayer, R. & Hari, U. An integrated methodology for fixture design. J Intell Manuf 7, 95–106 (1996). https://doi.org/10.1007/BF00177066

Issue Date:

DOI: https://doi.org/10.1007/BF00177066