Abstract

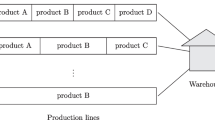

Research in experimental simulation of multi-stage inventory systems shows that a poor choice of lot-sizing heuristics has a significant degree of cost penalty and schedule instability. A realistic approach to a multi-stage system is to choose a suitable technique for a certain special circumstance rather than trying for a single best heuristic covering all cases. To avoid serious cost penalties and high schedule instability caused by inferior techniques, knowledge-based system technology could help practitioners to make a sensible choice of heuristics. In this paper, we develop a prototype knowledge-based system whose aim is to provide an acceptable lot-size schedule in a limited time which would hopefully lead to a good master production schedule.

Similar content being viewed by others

References

Afentakis, P., Gavish, B. and Karmarkar, U. (1984) Computational efficient optimal solutions to the lot-sizing problem in multi-stage assembly system.Management Science,30, 222–39.

Assad, A. and Golden, B. (1986) Expert systems, microcomputers and operations research.Computers and Operations Research,13, 301–21.

Axsater, S. (1986), Evaluation of lot-sizing techniques.International Journal of Production Research,24, 51–7.

Baker, K. (1977) An experimental study of the effectiveness of rolling schedule in production planning.Decision Sciences,8, 19–27.

Baker, K. and Peterson, D. (1979) An analytic framework for evaluating rolling schedules.Management Science,25, 341–51.

Barr, A. and Feigenbaum, E. (1982)The Handbook of Artificial Intelligence, William Kaufman Publishers, Inc., New York.

Biggs, J. (1979) Heuristic lot-sizing and sequencing rules in a multistage production-inventory system.Decision Sciences,10, 96–115.

Blackburn, J., Kropp, D. and Millen, R. (1986) A comparison of strategies to dampen nervousness in MRP systems.Management Science,32, 413–29.

Blackburn, J., Kropp, D. and Millen, R. (1987) Alternative approaches to schedule instability: a comparative analysis.International Journal of Production Research,25, 1739–49.

Blackburn, J. and Millen, R. (1980) Heuristic lot-sizing performance in a rolling schedule environment.Decision Sciences,11, 691–701.

Blackburn, J. and Millen, R. (1982a) Improved heristics for multi-stage requirements planning system.Management Science,28, 65–44.

Blackburn, J. and Millen, R. (1982b) The impact of a rolling schedule in a multi-level MRP system.Journal of Operational Management,2, 125–35.

Blackburn, J. and Millen, R. (1984) Simultaneous lot-sizing and capacity planning in multi-stage assembly process.European Journal of Operational Research,16, 84–93.

Boe, W. and Yilmaz, C. (1983) The incremental order quantity.Production and Inventory Management,24, 94–100.

Chakravarty, A. and Shtub, A. (1985) An experimental study of the efficiency of integer multiple lot sizes in multi-echelon production inventory systems.International Journal of Production Research,23, 469–78.

Chalmet, L., Debodt, M. and Wassenhove, L. (1985) The effect of engineering changes and demand uncertainty on MRP lot-sizing: a case study.International Journal of Production Research,23, 233–51.

Chand, S. (1982) A note on dynamic lot-sizing in a rolling-horizon environment.Decision Sciences,13, 113–9.

Chand, S. (1983) Rolling horizon procedures for the facilities in series inventory model with nested schedules.Management Science,29, 237–49.

Clark, A. and Scarf, H. (1960) Optimal police for a multi-echelon inventory problem.Management Science,6, 475–90.

Debodt, M., Gelders, L. and Wassenhove, L. (1984) Lot-sizing under dynamic demand conditions: a review.Engineering Costs and Production Economics,8, 165–87.

Debodt, M. and Wassenhove, L. (1983) Lotsizes and safety stocks in MRP: a case study.Production and Inventory Management,24, 1–16.

De Matties, J. (1968) An economic lot-sizing technique.IBM Systems Journal,7, 11–18.

Denning, P. (1986) Towards a science of expert systems.IEEE Expert,Summer, 80–90.

Dolk, D. and Konsynski, B. (1984) Knowledge representation for model management systems.IEEE Transactions on Software Engineering,SE-10, 619–28.

Elam, J. and Konsynski, B. (1987) Using artificial intelligence techniques to enhance the capabilities of model management systems.Decision Sciences,18, 487–502.

Feigenbaum, E. and McCorduck, P. (1984)The Fifth Generation (revised edn), Addison-Wesley New York.

Gaither, N. (1981) A near-optimal lot-sizing model for MRP systems.Production and Inventory Management,22, 75–88.

Groff, G. (1979) A lot sizing rule for time phased component demand.Production and Inventory Management,20, 47–53.

Gupta, Y. (1990) Some aspects of expert systems: applications in manufacturing.Technovation,10, 487–504.

Gupta, Y. and Chin, D. (1989) Expert systems and their applications in production and operations management.Computers and Operations Research,16, 567–82.

Gupta, Y. and Keung, Y. (1990a) A review of multi-stage lot-sizing models.International Journal of Operations and Production Management,10, 57–73.

Gupta, Y. and Keung, Y. (1990b) Comparative analysis of lot-sizing in multi-stage systems: a simulation study,a working paper, University of Louisville, KY, USA.

Hayes, R. and Clark, K. (1985) Explaining observed productivity differentials between plants implications for operations research.Interfaces,15, 3–14.

Kanet, J. and Adelsberger, H. (1987) Expert system in production scheduling.European Journal of Operational Research,21, 51–9.

Kastner, J. and Hong, S. (1984) A review of expert systems.European Journal of Operational Research,18, 285–92.

Kropp, D. and Carlson, R. (1984) A lot-sizing algorithm for reducing nervousness in MRP system.Management Science,30, 240–4.

Kusiak, A. (1987) Artificial intelligence and operations research in flexible manufacturing systems.Information systems and operations research,25, 2–12.

Kusiak, A. and Heragu, S. (1989) Expert systems and optimization.IEEE Transactions on Software Engineering,15, 1017–20.

Liang, T. P. (1988) Model management for group decision support.MIS Quarterly,December, 667–80.

Love, S. (1979)Inventory Control, McGraw-Hill, New York.

McLaren, B. (1976) A study of multiple level lot sizing techniques for material requirement planning system. PhD dissertation, Purdue University.

Minifie, R. and Davis, R. (1986) Survey of MRP nervousness issues.Production and Inventory Management,27, 111–20.

Orlicky, J. (1975)Material Requirement Planning, McGraw-Hill, New York.

Parlar, M. (1989) EXPIM: a knowledge based expert system for production/inventory modeling.International Journal of Production Research,27, 101–18.

Schwarz, L. and Schrage, L. (1975) Optimal and system myopic polices for multi-echelon production-inventory systems.Management Science,21, 1285–94.

Silver, E. and Meal, H. (1973). A heuristic for selecting lot size quantities for deterministic time-varying demand rate and discrete opportunities for replenishment.Production and Inventory Management,14, 64–74.

Silver, E. and Peterson, R. (1985)Decision System for Inventory Management and Production Planning (2nd edn), John Wiley, New York.

Simon, H. (1981)The Science of the Artificial, MIT Press, Cambridge, MA.

Sprague, R. and Carlson, E. (1982)Building Effective Decision Support Systems, Prentice Hall, Englewood Cliffs, NJ.

Sridharan, S., Berry, W. and Udayabhanu, V. (1987) Freezing the master production schedule under rolling planning horizons.Management Science,33, 1137–49.

Sridharan, S., Berry, W. and Udayabhanu, V. (1988) Measuring master production schedule stability under rolling planning horizons.Decision Sciences,19, 147–66.

Steffen, M. (1986) A survey of artificial intelligence based scheduling systems, inIIE 1986 Fall Industrial Engineering Conference Proceedings.

Stohr, E. and Tanniru, M. (1980) A database for operations research models.International Journal of Policy Analysis and Information Systems,4, 105–21.

Szendrovits, A. (1978) A comment on ‘Optimal and system myopic policies for multi-echelon production/inventory assembly system’.Management Science,24, 863–4.

Wagner, H. and Whitin, T. (1959) Dynamic version of the economic lot size model.Management Science,5, 89–96.

Waterman, D. (1986)A Guide to Expert Systems, Addison-Wesley, New York.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Gupta, Y.P., Keung, Y.K. KBLS: A prototype knowledge-based system for the selection of lot-sizing models. J Intell Manuf 2, 199–211 (1991). https://doi.org/10.1007/BF01471107

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF01471107