Abstract

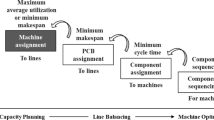

We consider an operation assignment problem that arose from a printed circuit (PC) board assembly process. Components can either be inserted on boards manually or by machine. The objective is to determine an assignment of components (operations) to a set of capacitated machines (with the remainder of the components inserted manually) to minimize the total set-up and processing cost for assembling all boards. The problem can be formulated as a mixed integer linear program, but is too large to be practically solved. For the case of one machine, we present two different solution heuristics. We show that while each can be arbitrarily bad, on average the algorithms perform quite well. For the case of multiple machines, we present four different solution heuristics. We discuss implementation of our results at Hewlett-Packard.

Similar content being viewed by others

References

Ahmadi, J., Grotzinger, S. and Johnson, D. (1986) Component allocation and partitioning for a dual delivery machine.Research Paper, IBM T. J. Watson Research Center, USA.

Ammons, J. C., Lofgren, C. B. and McGinnis, L. F. (1985) A large sclae machine problem in flexible assembly.Annals of Operations Research,3, 319–22.

Chakravarty, A. K. and Schtub, A. (1984) Selecting Parts and Loading an FMS, inProceedings of the First ORSA/TIMS Conference on Flexible Manufacturing Systems. University of Michigan, Ann Arbor, USA.

Crama, Y., Kolen, A. W. J. and Oerlmans, A. G. (1991) Throughput rate optimization in the automated assembly of printed circuit boards.Annals of Operations Research, to be published.

Davis, T. (1990) Group Technology for PCBA: Applving the ‘Greedy Board’ Cell Heuristic.Technical Report, Hewlett-Packard Co., California, USA.

Fisher, M. (1980) Worst case analysis of heuristic algorithms.Management Science,26, 1–17.

Kouvelis, P. and Lee, H. L. (1991) Block angular structures and the loading problem in flexible manufacturing systems.Operations Research, to be published.

Kusiak, A. and Chow, W. S. (1988) Decomposition of Manufacturing Systems,IEEE Journal of Robotics and Automation,4, 457–71.

Langston, M. A. (1987) A Study of composite heuristic algorithms.J. of Operational Research Society,38, 539–44.

Sarin, S. C. and Chen, S. C. (1987) The machine loading and tool allocation problem in an FMS.International Journal of Production Research,25, 1081–94.

Stecke, K. E. (1983) Formulation and solution of nonlinear integer production planning problems for flexible manufacturing systems.Management Science,29, 273–88.

Tang, C. S. and Denardo, E. (1988a) Models arising from a flexible manufacturing machine—Part I: minimizing of the number of tools switches.Operations Research,36, 767–77.

Tang, C. S. and Denardo, E. (1988b) Models arising from a flexible manufacturing machine—Part II: minimizing of the number of switchin instants.Operations Research,36, 778–84.

Welker, D. (1988) Low volume production using high volume equipment.Printed Circuit Assembly.February, 6–10.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Brandeau, M.L., Billington, C.A. Design of manufacturing cells: Operation assignment in printed circuit board manufacturing. J Intell Manuf 2, 95–106 (1991). https://doi.org/10.1007/BF01471222

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF01471222