Abstract

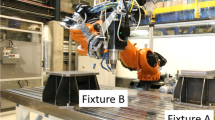

Incremental automation, i.e. adding capabilities over time, is an alternative for small mannfacturers to large scale automation projects as a method of achieving automated manufacturing. As an example of incremental automation, the University of Kansas Computer Integrated Manufacturing (KUCIM) workstation has developed over time into an unmanned flexible machining workstation. Presently, the workstation contains a Hurco three-axis milling machine, an American Robot six-axis robot, a Sun 4/260, a versatile fixturing system, an IBM PC-AT compatible computer, and an interface between the milling machine and PC. The control architecture is based on the National Institute for Standards and Technology (NIST) Automated Manufacturing Research Facility (AMRF) manufacturing control hierarchy. The workstation controller employs three software modules: the Supervisor, the Robot Foreman, and the Fixture/Machine Tool Foreman. At the equipment level, two modules are used: the Robot Command Interpreter and the Fixture/Machine Tool Command Interpreter. The three functions that the KUCIM workstation performs to produce parts are: processing an input file, performing tool zeroing and performing machining cycles.

Similar content being viewed by others

Explore related subjects

Discover the latest articles and news from researchers in related subjects, suggested using machine learning.References

Bloom, H. M. and McLean, C. R. (1985) Standardization suggested by the automated manufacturing research facility (AMRF)—a research testbed for the factory of the future, inAutomated Manufacturing, ASTM STP 862, Gardner, L. B. (ed.), American Society for Testing and Materials, Philadelphia, PA, pp. 38–60.

Frechette, S. (1987) Development of a prototype flexible fixturing system for prismatic parts, Master's Thesis, University of Kansas, Lawrence.

Hoffman, E. G. (1984) (ed.), ch. 4 inFundamentals of Tool Design, Society of Manufacturing Engineers Publications/Marketing Division, Dearborn, MI, pp. 142–7.

Hoffman, E. G. (1987) ch. 2 inModular Fixturing, Manufacturing Technology Press, Inc., Lake Geneva, WI, pp. 12–20.

Hurco, (1985)KM-3P Three-Axis Milling Machine Owner's Manual, Hurco Manufacturing Company, pp. 3–17.

Jones, A. T. and McLean, C. R. (1985) A production control module for the AMRF, inProceedings of Summer 1985 ASME Conference, Boston, MA.

Jones, A. T. and McLean, C. R. (1986) A proposed hierarchical control model for automated manufacturing systems.Journal of Manufacturing Systems 5, 15–25.

Magrab, E. (1986) The vertical machining workstation of the AMRF: equipment integration, inProceedings of the 1986 ASME Symposium on Intelligent and Integrated Manufacturing, Anaheim, CA. pp. 83–100.

McLean, C. R. (1985) An architecture for intelligent manufacturing control, inProceedings of Summer 1985 ASME Conference, Boston, MA.

McLean, C. R. (1986a) Information architecture of the automated manufacturing research facility, inProceedings of the Informational Technologies Conference, Troy, NY.

McLean, C. R. (1986b) The vertical machining workstation of the AMRF: software integration, inProceedings of the 1986 ASME Symposium on Intelligent and Integrated Manufacturing, Anaheim, CA, pp. 101–16.

McLean, C. R., Mitchell, M. and Barkmeyer, E. (1983) A computing architecture for small batch manufacturing.IEEE Spectrum, 59–64.

Nakpalohpo, I., Faddis, T. N. and Barr, B. (1989) Development and integration of the KUCIM vertical machining workstation for the automated manufacture of prismatic parts, inProceedings of the Second International Conference on Industrial and Engineering Applications of Artificial Intelligence and Expert Systems.

Nanzetta, P. (1984) Update: NBS research facility addresses problems in setups for small batch manufacturing.Industrial Engineering 68–73.

Owen, J. V. (1990a) Flexible cells & machining centers.Manufacturing Engineering, 24–8.

Owen, J. V. (1990b) CIM for the small shop,Manufacturing Engineering, 65–9.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Xie, Z., Bluethmann, B., Faddis, T. et al. Advancements of the KUCIM automated flexible manufacturing workstation. J Intell Manuf 3, 183–191 (1992). https://doi.org/10.1007/BF01477601

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF01477601