Abstract

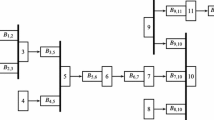

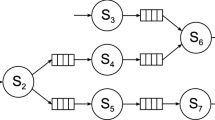

In several instances ofdiscrete event dynamic systems (DEDS), jobs sometimes require service from two or more resources at the same time. When queueing network models are used to study DEDS, this feature ofsimultaneous resource possession is often ignored because it is difficult for the models to handle. In some DEDS, this feature of a job demanding several resources simultaneously can have a significant effect on system performance, especially if there is a limited amount of one or more of these resources. For example, in an asynchronous automatic assembly system, an assembly at a workstation needs an operator when it experiences a jam (a random phenomenon) in order to clear the jam. Due to the presence of a limited (small) number of operators, an assembly may have to wait for an operator. This waiting orinterference time has a significant effect on the system production rate. This paper develops an analytical approximation method that can be used to determine the steady-state performance of automatic assembly systems for a given assignment of operators. The analytical method involves the simultaneous solution of two “coupled” queueing models; one of the models calculates the waiting time for an operator resource, while the other computes the waiting time for a workstation resource. The solution technique developed can be adapted to study instances of simultaneous resource possession in other DEDS, such as flexible manufacturing systems and computer/communication networks.

Similar content being viewed by others

References

S.R. Agnihothri, “Interrelationships between performance measures for the machine-repairman problem,”Naval Res. Logist., vol. 36, pp. 265–271, 1989.

H. Ashcroft, “The productivity of several machines under the care of one operator,”J. Roy. Statist. Soc. B, vol. 12, pp. 145–151, 1950.

F. Benson, and D.R. Cox, “The productivity of machines requiring attention at random intervals,”J. Roy. Statist. Soc. B, vol. 13, pp. 65–82, 1951.

G. Boothroyd, C. Poli, and L.E. Murch,Automatic Assembly Systems, New York: Marcel Dekker, 1982.

A.A. Bulgak, M. Kamath, and J.L. Sanders, “Research on the dynamics and design optimization of automatic assembly systems,” inProc. 15th Conf. Production Research and Technology, SME, pp. 275–283, 1989.

Y. Dallery, “On modelling flexible manufacturing systems using closed queueing networks,”Large Scale Systems, vol. 11, pp. 109–119, 1986.

E. de Souza e Silva and R.R. Muntz, “Approximate solutions for a class of nonproduct form queueing networks,”Perform. Eval., vol. 7, p. 221–242, 1987.

A.A. Fredericks, “An approximation method for analyzing a virtual circuit switch based LAN-solving the simultaneous resource possession problem,” inTeletraffic Analysis and Computer Performance Evaluation (O.J. Boxma, J.W. Cohen, and H.C. Tijms (eds.)), Elsevier: Amsterdam, pp. 63–74, 1987.

D. Gross, and C.M. Harris,Fundamentals of Queueing Theory, New York: Wiley 1985.

Y.C. Ho, “Performance evaluation and perturbation analysis of discrete event dynamic systems,”IEEE Trans. Automat. Control, vol. AC-32, pp. 563–572, 1987.

P.A. Jacobson, and E.D. Lazowska, “Analyzing queueing networks with simultaneous resource possession,”Comm. ACM, vol. 25, pp. 142–151, 1982.

M. Kamath, “A numerical investigation of an approximation method for calculating the mean and variance of the interference time in a general machine-repairman model,” Working Paper, Center for Computer Integrated Manufacturing, Oklahoma State University, Stillwater, OK, 1990.

M. Kamath, and J.L. Sanders, “Analytical methods for performance evaluation of large asynchronous automatic assembly systems,”Large Scale Systems, vol. 12, pp. 143–154, 1987.

M. Kamath, R. Suri, and J.L. Sanders, “Analytical performance models for closed loop flexible assembly systems,”Int J. Flexible Manufac. Syst. vol. 1, pp. 51–84, 1988.

W. Kraemer and M. Langenbach-Belz, “Approximate formulae for the delay in the queueing system GI/G/l,” inProc. Eighth Int. Teletraffic Cong., Melbourne, pp. 235.1–235.8, 1976.

P.J. Kuehn, “Approximate analysis of general queueing networks by decomposition,”IEEE Trans. Comm., vol. 27, pp. 113–126, 1979.

Y.T. Leung and M. Kamath, “Performance analysis of synchronous production lines,”IEEE Trans. Robotics Automat., vol. 7, pp. 1–8, 1991.

K.T. Marshall, “Some inequalities in queueing,”Oper. Res., vol. 16, pp. 651–665, 1968.

J. Palesano and J. Chandra, “A machine interference problem with multiple types of failures,”Int. J. Prod. Res., vol. 24, pp. 567–582, 1986.

K.R. Pattipati and M.P. Kastner, “A hierarchical queueing network model of a large electronics test facility,”Inform. Decision Technol., vol. 14, pp. 45–64, 1988.

J.G. Shanthikumar and J.A. Buzacott, “On the approximations to the single server queue,”Int. J. Prod. Res., vol. 18, pp. 129–151, 1980.

J.G. Shanthikumar and M. Gocmen, “Heuristic analysis of closed queueing networks,”Int. J. Prod. Res., vol. 21, pp. 675–690, 1983.

K.E. Stecke, “Machine interference: The assignment of machines to operators,” inHandbook of Industrial Engineering, G. Salvendy (ed.), New York: Wiley, 1982.

K.E. Stecke and J.E. Aronson, “Review of operator/machine interference models,”Int. J. Prod. Res., vol. 23, pp. 129–151, 1985.

R. Suri and R.R. Hildebrant, “Modeling flexible manufacturing systems using mean-value analysis,”J. Manufact. Syst., vol. 3, pp. 27–38, 1984.

W. Whitt, “The queueing network analyzer,”Bell Syst. Tech. J., vol. 62, pp. 2779–2815, 1983.

Author information

Authors and Affiliations

Additional information

This research was supported in part by a grant from the General Motors Research Laboratories and NSF grant no. DMC 8608409.

Rights and permissions

About this article

Cite this article

Kamath, M., Sanders, J.L. Modeling operator/workstation interference in asynchronous automatic assembly systems. Discrete Event Dyn Syst 1, 93–124 (1991). https://doi.org/10.1007/BF01797144

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF01797144