Abstract

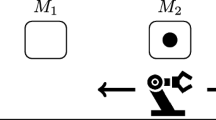

The paper deals with the scheduling of a robotic cell in which jobs are processed on two tandem machines. The job transportation between the machines is done by a transportation robot. The robotic cell has limitations on the intermediate space between the machines for storing the work-in-process. What complicates the scheduling problem is that the loading/unloading operation times are non-negligible. Given the total number of operationsn, an optimalO(n logn)-time algorithm is proposed together with the proof of optimality.

Similar content being viewed by others

References

A.S. Belen'kii and E.V. Levner, Scheduling models and methods in optimal freight transportation planning, Auto. Remote Contr. 10(1991)1–56.

T. Blazewicz, G. Finke, R. Haupt and G. Schmidt, New trends in machine scheduling, Euro. J. Oper. Res. 37(1988)303–317.

S.M. Johnson, Optimal two- and three-stage production scheduling with setup times included, Naval. Res. Log. Quart. 1(1954)61–68.

H. Kise, T. Shioyama and T. Ibaraki, Automated two-machine flowshop scheduling: A solvable case, IIE Trans. 23(1991)10–16.

A. Kusiak, Scheduling flexible machining and assembly systems, in:Flexible Manufacturing Systems. Operations Research Models and Applications, ed. K.E. Stecke and R. Suri (Elsevier, New York, 1986) pp. 521–532.

E.L. Lawler, J.K. Lenstra, A.H.G. Rinnooy Kan and D.B. Shmoys, Sequencing and scheduling: Algorithms and complexity, in:Logistics of Production and Inventory, Handbooks in Operations Research and Management Science, Vol. 4, ed. S. Graves, A. Rinnooy Kan and P. Zipkin (North-Holland, New York, 1993).

E.V. Levner, Optimal planning of part's machining on a number of machines, Auto. Remote Contr. 11(1969)1972–1979.

S.S. Panwalkar, Scheduling of a two-machine flowshop with travel time between machines, J. Oper. Res. Soc. 42(1991)609–613.

R.E. Stecke and R. Suri (eds.),Flexible Manufacturing Systems: Operations Research Models and Applications (Elsevier, New York, 1986).

H.I. Stern and G. Vitner, Scheduling parts in a combined production-transportation work cell, J. Oper. Res. Soc. 41(1990)625–632.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Levner, E., Kogan, K. & Levin, I. Scheduling a two-machine robotic cell: A solvable case. Ann Oper Res 57, 217–232 (1995). https://doi.org/10.1007/BF02099699

Issue Date:

DOI: https://doi.org/10.1007/BF02099699