Abstract.

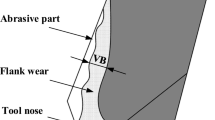

The texture of machined surfaces provides reliable information regarding the extent of tool wear. In this paper, we propose a structure-based approach to analyzing machined surfaces. The original surface images are first preprocessed by a Canny edge detector. A new connectivity-oriented fast Hough transform is then applied to the edge image to detect all the line segments. The distributions of the orientations and lengths of the line segments are used to determine tool wear. Through our experiments, we found a strong correlation between tool wear and features. The computational complexity of the fast Hough transform is also analyzed.

Similar content being viewed by others

References

Aghajan HK, Kailath T (1994) SLIDE: subspace-based line detection. IEEE Trans Patt Anal Mach Intell 16:1057-1073

Byrne G, Dornfeld D, Inasaki I, Ketteler G, König W, Teti R (1995) Tool condition monitoring (TCM) - the status of research and industrial application. Ann CIRP 44/2:541-567

Canny JF (1986) A computational approach to edge detection. IEEE Trans Patt Anal Mach Intell 8:679-698

Dimla E, Dimla S (2000) Sensor signals for tool-wear monitoring in metal cutting operations - a review of methods. Int J Mach Tools Manuf 40:1073-1098

Gu J, Barber G, Jiang Q, Tung S (2001) Surface roughness model for worn inserts of face milling: I. Factors that affect arithmetic surface roughness. Tribol Trans 44:47-52

Guil N, Villalba J, Zapata EL (1995) A fast transform for segment detection. IEEE Trans Image Process 4:1541-1548

Jemielniak K (1999) Commercial tool condition monitoring systems. Int J Adv Manuf Technol 15:711-721

Kassim AA, Tan T, Tan KH (1999) A Comparative Study of efficient generalised Hough transform techniques. Image Vision Comput 17:737-748

Kassim AA, Zhu M, Mannan MA (2002) Texture analysis of machined surfaces using a new Hough transform. In: Proceedings of Texture 2002, the 2nd international workshop on texture analysis and synthesis, Copenhagen

Kultanen P, Xu L, Oja E (1990) Randomized Hough transfrom (RHT). In: Proceedings of the 10th international conference on pattern recognition 1:631-635

Kurada S, Bradley C (1997a) A review of machine vision sensors for tool condition monitoring. Comput Ind 34:55-72

Kurada S, Bradley C (1997b) A machine vision system for tool wear assessment. Tribol Int 30:295-304

Kälviäinen H, Hirvonen P, Xu L, Oja E (1995) Probabilistic and nonprobabilistic Hough transforms: overview and comparisons. Image Vision Comput 13:239-252

Kälviäinen H, Hirvonen P (1997) An extension to the randomized Hough transform exploiting connectivity. Patt Recog Lett 18:77-85

Mannan MA, Kassim AA, Jing M (2000) Application of image and sound analysis techniques to monitor the condition of cutting tools. Patt Recog Lett 21:969-979

McLaughlin RA, Alder MD (1998) The Hough transform versus the UpWrite. IEEE Trans Patt Anal Mach Intell 20:396-400

Pfeifer T, Wiegers L (2000) Reliable tool wear monitoring by optimized image and illumination control in machine vision. Measurement 28:209-218

Shpilman R, Brailovsky V (1999) Fast and robust techniques for detecting straight line segments using local modals. Patt Recog Lett 20:865-877

Yang M-y, Kwon O-d (1998) A tool condition recognition system using image processing. Control Eng Pract 6:1389-1395

Yang MCK, Lee J-S, Lien C-C, Huang C-L (1997) Hough transform modified by line connectivity and line thickness. IEEE Trans Patt Anal Mach Intell 19:905-910

Author information

Authors and Affiliations

Corresponding author

Additional information

Received: 6 November 2002, Accepted: 18 December 2003, Published online: 13 May 2004

Correspondence to: A.A. Kassim

Rights and permissions

About this article

Cite this article

Mannan, M.A., Mian, Z. & Kassim, A.A. Tool wear monitoring using a fast Hough transform of images of machined surfaces. Machine Vision and Applications 15, 156–163 (2004). https://doi.org/10.1007/s00138-004-0137-6

Issue Date:

DOI: https://doi.org/10.1007/s00138-004-0137-6