Abstract.

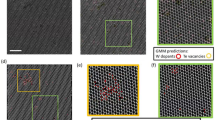

Manual methods of defect detection and classification on silicon carbide (SiC) wafers are tedious, time consuming, and prone to error. We have developed a nondestructive optical stress technique (photoelasticity) to isolate structural defects on SiC wafers. The technique is rapid, nondestructive, and inexpensive. In this paper we present an image processing system that exploits the optical system to detect structural defects on SiC wafers automatically. We are specifically interested in detecting defects known as micropipes. The philosophy of our approach is to reduce the dependency of the environment factors, image acquisition factors, and user parameters while maintaining the performance and computational speed. The goal is achieved by careful study of patterns that are invariant to the contrast and shift of pixel intensities and a combination of simple image processing techniques that are locally adaptive.

Similar content being viewed by others

References

Haykin S (1999) Neural networks: a comprehensive foundation, 2nd edn. Prentice-Hall, Englewood Cliffs, NJ

Kalinina E, Zubrilov A, Kuznetsov N, Nikitina I, Tregubova A, Shcheglov M, Bratus V (2000) Structural, electrical and optical properties of bulk 4h and 6h p-type sic. Mater Sci Forum 338:497-500

Kato T, Ohsato H, Okamoto A, Sugiyama N, Okuda T (1999) The photoelastic constant and internal stress around micro-pipe defects of 6h-sic single crystal. Mater Sci Eng B57:147-149

Kato T, Ohsato H, Okuda T (2000) Origin of the internal stress around the micro-pipe of 6h-sic single crystal. Mater Sci Forum 338:449-452

Ma X, Parker M, Sudershan TS (2002) Nondestructive defect delineation in sic wafers based on an optical stress technique. Appl Phys Lett 80(18):3298-3300

Müller S, Glass R, Hobgood H, Tsvetkov V, Brady M, Henshall D, Malta D, Singh R, Palmour J, Carter C (2001) Progress in the industrial production of sic substrates for semiconductor devices. Mater Sci Eng B80:327-331

Morel J-M, Solimini S (1994) Variational methods in image segmentation. Birkhäuser, Boston

Pal N, Pal S (1993) A review on image segmentation techniques. PR 26(9):1277-1294

Shi J, Malik J (1997) Normalized cuts and image segmentation. In: CVPR’97, Puerto Rico

Author information

Authors and Affiliations

Corresponding author

Additional information

Received: 27 January 2004, Accepted: 7 October 2004, Published online: 5 April 2005

Rights and permissions

About this article

Cite this article

Kubota, T., Talekar, P., Ma, X. et al. A nondestructive automated defect detection system for silicon carbide wafers. Machine Vision and Applications 16, 170–176 (2005). https://doi.org/10.1007/s00138-004-0169-y

Issue Date:

DOI: https://doi.org/10.1007/s00138-004-0169-y