Abstract

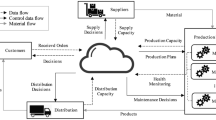

In this article, we propose a novel availability management process called Available-to-Sell (ATS) that incorporates demand shaping and profitable demand response to drive better supply chain efficiency. The proposed process aims at finding marketable product alternatives in a quest to maintain a financially viable and profitable product portfolio, and to avoid costly inventory overages and shortages. The process is directly supported by a mathematical optimization model that enables on demand up-selling, alternative-selling and down-selling to better integrate the supply chain horizontally, connecting the interaction of customers, business partners and sales teams to procurement and manufacturing capabilities of a firm. We outline the business requirements for incorporating such a process into supply chain operations, and highlight the advantages of ATS through simulations with realistic production data in a computer manufacturing environment. The models featured in this paper have contributed to substantial business improvements in industry-size supply chains, including over $100M of inventory reduction in IBM’s server computer supply chain.

Similar content being viewed by others

References

Akcay Y and Xu S (2004). Joint inventory replenishment and component allocation optimization in an assemble-to-order system. Manage Sci 50: 99–116

Balakrishnan A and Geunes J (2000). Requirements planning with substitutions: exploiting bill-of-materials flexibility in production planning. Manuf Serv Oper Manage 2(2): 166–185

Balakrishnan A and Geunes J (2003). Production planning with flexible product specifications: an application to specialty steel manufacturing. Oper Res 51(1): 94–112

Balakrishnan A, Xia Y, Zhang B (2005) Shaping demand to match anticipated supply. In: MSOM Conference 2005, Northwestern University

Ball MO, Chen CY and Zhao ZY (2004). Available to promise. In: Simchi-Levi, D, Wu, SD, and Shen, ZJ (eds) Handbook of quantitative supply chain analysis—modeling in the e-business era, pp 447–480. Kluwer, New York

Bassok Y, Anupindi R and Akella R (1999). Single-period multiproduct inventory models with substitution. Oper Res 47(4): 632–642

Cecere L, Hofman D, Martin R, Preslan L (2005) The handbook for becoming demand driven. AMR Research

Chen C-Y, Zhao Z and Ball MO (2002). A model for batch advanced available-to-promise. Prod Oper Manage 11: 424–440

Chen-Ritzo C-H (2006) Availability management for configure-to-order supply chain systems. PhD Dissertation, Pennsylvania State University

Dietrich B, Connors D, Ervolina T, Fasano JP, Lougee-Heimer R and Wittrock R (2005). Applications of implosion in manufacturing. In: An, C and Fromm, H (eds) Supply chain management on demand, pp 97–115. Springer, Heidelberg

Ervolina T, Dietrich B (2001) Moving toward dynamic available-to-promise. In: Gass S, Jones AT (eds) Supply chain management practice and research: status and future directions, pp 1–19

Gallego G, Katircioglu K and Ramachandran B (2006). Semiconductor inventory management with multiple grade parts and downgrading. Prod Plann Cont 17(7): 689–700

Hale W, Pyke DF, Rudi N (2001) An assemble-to-order system with component substitution. Working Paper, Tuck School of Business at Dartmouth

Hopp WJ and Roof Sturgis M (2001). A simple, robust lead time-quoting policy. Manuf Serv Oper Manage 3(4): 321–336

Hopp W and Spearman M (2000). Factory physics, 2nd edn. McGraw-Hill/Irwin, New York

Kilger C and Schneeweiss L (2000). Demand fulfillment and ATP. In: Stadtler, H and Kilger, C (eds) Supply chain management and advanced planning: concepts, models, software and case studies, pp 179–196. Springer, Heidelberg

Lee YM (2006) Analyzing the effectiveness of availability management process. In: Jung H, Chen FF, Jeong B (eds) Trends in supply chain design and management: technologies and methodologies. Springer, Heidelberg

Moses S, Grant H, Gruenwald L and Pulat S (2004). Real-time due-date promising by build-to-order environments. Int J Prod Res 42(20): 4353–4375

O’Marah K, Souza J (2004) DDSN: 21st century supply on demand. AMR Research

Swaminathan JM and Tayur SR (1998). Managing broader product lines through delayed differentiation using vanilla boxes. Manage Sci 44(12): S161–S172

Yunes TH, Napolitano D, Scheller-Wolf A and Tayur S (2007). Building efficient product portfolios at John Deere and Company. Oper Res 55(4): 615–629

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ervolina, T.R., Ettl, M., Lee, Y.M. et al. Managing product availability in an assemble-to-order supply chain with multiple customer segments. OR Spectrum 31, 257–280 (2009). https://doi.org/10.1007/s00291-007-0113-4

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00291-007-0113-4