Abstract

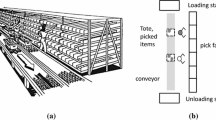

As the transactions through electronic commerce and TV home shopping increase, the warehouses often receive a large amount of small orders to be picked within tight time windows. One of the important warehousing activities is order picking, the process of retrieving a number of items from warehouse storage to meet a number of independent customer orders. This paper examines a new order picking method, bucket brigade order picking (BB picking). Bucket brigade is a way of coordinating workers who progressively perform a set of operations on a flow line. In the BB picking system, a worker performs operations on an order until the next worker downstream takes it over; then goes back to the previous worker upstream to take over a new order. We discuss distinct characteristics in order picking systems when bucket brigades are applied. We identify some efficiency losses under the BB picking and present a new BB picking protocol to improve the performance of order picking systems. The new BB picking is compared with the existing BB picking and zone picking through simulation experiments.

Similar content being viewed by others

References

Anderson C, Boomsma JJ, Bartholdi JJ (2002) Task partitioning in insect societies: bucket brigades. Insect Soc 49: 1–10

Bartholdi JJ, Eisenstein DD (1996) A production line that balances itself. Oper Res 44(1): 21–34

Bartholdi JJ, Eisenstein DD (1998) Bucket brigades: a self-organizing scheme for sharing work. Working paper

Bartholdi JJ, Eisenstein DD, Foley RD (2001) Performance of bucket brigades when work is stochastic. Oper Res 49(5): 710–719

Bartholdi JJ, Eisenstein DD (2005) Using bucket brigades to migrate from craft manufacturing to assembly lines. Manuf Serv Oper Manage 7(2): 121–129

Bartholdi JJ, Eisenstein DD, Lim YF (2006) Bucket brigades on in-tree assembly networks. Eur J Oper Res 168(3): 870–879

Bartholdi JJ, Eisenstein DD, Lim YF (2008) Chaos and convergence in bucket brigades with finite walk-back velocities. Oper Res (in press)

Bratcu AI, Dolgui A (2005) A survey of self-balancing production lines (“bucket brigade”). J Intell Manuf 16: 139–158

De Koster R (1994) Performance approximation of pick-to-belt order picking systems. Eur J Oper Res 72(3): 558–573

De Koster R, Le-Duc T, Roodbergen KJ (2007) Design and control of warehouse order picking: a literature review. Eur J Oper Res 182: 481–501

Gray AE, Karmarkar US, Seidmann A (1992) Design and operation of an order-consolidation warehouse: models and applications. Eur J Oper Res 58(1): 14–36

Gu J, Goetschalckx M, McGinnis LF (2007) Research on warehouse operation: a comprehensive review. Eur J Oper Res 177(1): 1–21

Jane C-C (2000) Storage location assignment in a distribution center. Int J Phys Distrib Logistics Manage 30(1): 55–71

Jane CC, Laih Y-W (2005) A clustering algorithm for item assignment in a synchronized zone order picking system. Eur J Oper Res 166: 489–496

Jewkes E, Lee C, Vickson R (2004) Product location, allocation and server home base location for an order picking line with multiple servers. Comput Oper Res 31: 623–636

Le-Duc T, De Koster R (2005) Determining the optimal number of zones in a pick-and-pack order picking system. Report ERS-2005–029-LIS, RSM Erasmus University, The Netherlands

Parikh PJ, Meller R (2008) Selecting between batch and zone order picking strategies in a distribution center. Transport Res E (in press)

Peterson CG (2002) Considerations in order picking zone configuration. Int J Oper Prod Manage 27(7): 793–805

Schultz KL, McClain JO, Thomas LJ (2003) Overcoming the dark side of work flexibility. J Oper Manage 21: 81–92

Tompkins JA, White JA, Bozer YA, Frazelle EH, Tanchoco JMA, Trevino J (2003) Facilities planning. Wiley, New York

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Koo, PH. The use of bucket brigades in zone order picking systems. OR Spectrum 31, 759–774 (2009). https://doi.org/10.1007/s00291-008-0131-x

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00291-008-0131-x