Abstract

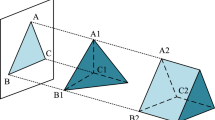

Due to the rapid development of computer, sensor, and automatic control technologies, the amount of data generated during product design and manufacturing is increasing significantly. The product data bank is large, complex, heterogeneous, and often fast-changing; it is difficult to integrate heterogeneous models using the conventional method. Therefore, a semantic feature fusion-based heterogeneous model integration method is proposed. First, the error in the geometric dimensions and position are extracted using model registration. Second, the basic geometric feature is obtained using slippage analysis. Third, the extracted data, such as the basic geometric feature and the error in the geometric dimensions and position, are fused into the design model using the level set method. Finally, the marching cubes method is introduced to reconstruct the surface of the fused model. The empirical results demonstrate that the proposed algorithm can integrate all types of semantic features and geometric features into a basic product model effectively and efficiently.

Similar content being viewed by others

References

Marek O, Vaclav J (2015) Big data semantics in industry 4.0. In: Proceedings of the 7th international conference of industrial applications of holonic and multi-agent systems, pp 217–229

Bidarra R, Bronsvoort WF (2000) Semantic feature modeling. Comput Aided Des 32:201–225

Sanfilippo EM, Borgo S (2016) What are feature? An ontology-based review of the literature. Comput Aided Des 80:9–18

Bianconi F (2002) Bridging the gap between CAD and CAE using STL files. Int J CAD/CAM 2(1):55–67

Cao B, Chen J, Huang Z et al (2009) CAD/CAE integration framework with layered software architecture. In: IEEE international conference on computer-aided design and computer graphics, pp 410–415

Song I, Han S (2013) Implementation of the direct integration from CAM to CAE for the PCB simulation. Comput Ind 64(8):1014–1021

Wang X, Xu X (2015) A collaborative product data exchange environment based on STEP. Int J Comput Integr Manuf 28(1):75–86

Louhichi B, Tlija M, Benamara A et al (2015) An algorithm for CAD tolerancing integration: generation of assembly configurations according to dimensional and geometrical tolerances. Comput Aided Des 62:259–274

Gujarathi GP, Ma Y-S (2011) Parametric CAD/CAE integration using a common data model. J Manuf Syst 30(3):118–132

Lee SH (2005) A CAD-CAE integration approach using feature-based multi-resolution and multi-abstraction modelling techniques. Comput Aided Des 37(9):941–955

Xu X, Wang Y (2002) Multi-model technology and its application in the integration of CAD/CAM/CAE. J Mater Process Technol 129(1–2):563–567

Zhou X, Qiu Y, Hua G et al (2007) A feasible approach to the integration of CAD and CAPP. Comput Aided Des 39(4):324–338

Louhichi B, Abenhaim GN, Tahan AS (2015) CAD/CAE integration: updating the CAD model after a FEM analysis. Int J Adv Manuf Technol 76(1–4):391–400

Lorensen WE, Cline HE (1987) Marching cubes: a high resolution 3d surface construction algorithm. ACM Comput Graph 21(4):163–169

Newman TS, Hong Y (2006) A survey of the marching cubes algorithm. Comput Graph 30(5):854–879

Garzon M, Gray L, Sethian JA (2009) Numerical simulation of non-viscous liquid pinch off using a coupled level set-boundary integral method. J Comput Phys 228(17):6079–6106

Sethian JA, Smereka P (2003) Level set methods for fluid interfaces. Annu Rev Fluid Mech 35:341–372

Nguyen TH, Paulino GH, Song J et al (2010) A computational paradigm for multiresolution topology optimization (MTOP). Struct Multidiscip Optim 41(4):525–539

Andreassen E, Clausen A, Schevenels M et al (2011) Efficient topology optimization in MATLAB using 88 lines of code. Struct Multidiscip Optim 43(1):1–16

Liu J, Cheng Z, Ma Y (2016) Product design-optimization integration via associative optimization feature modeling. Adv Eng Inform 30:713–727

Liu J, Ma Y (2017) Sustainable design-oriented level set topology optimization [J]. J Mech Design 139:011403-1-8

Yi B, Liu Z, Tan J, Cheng F, Duan G, Liu L (2014) Shape recognition of CAD models via iterative slippage analysis [J]. Comput Aided Des 55(10):13–25

Besl P, McKay N (1992) A method for registration of 3-D shapes. IEEE Trans Pattern Anal Mach Intell 14(2):239–256

Acknowledgements

The support of the National Natural Science Foundation of China (Grant Nos. 51605495, 61271356 and 51575541) and the Natural Science Foundation of Hunan Province of China (Grant No. 2015JJ2168) for this research is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yi, B., Li, X. & Yang, Y. Heterogeneous model integration of complex mechanical parts based on semantic feature fusion. Engineering with Computers 33, 797–805 (2017). https://doi.org/10.1007/s00366-016-0498-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00366-016-0498-2