Abstract

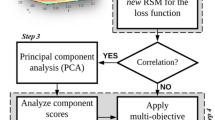

This paper proposes a combined approach using the normal boundary intersection (NBI) and multivariate mean square error (MMSE) that is an alternative approach to outperform the traditional NBI driving to an equispaced Pareto Frontier in a low-dimension space with a considerable reduction in the number of iterations. The method participating in the evolutionary stage of creating a uniformly spread Pareto Frontier for a nonlinear multi-objective problem is the NBI using normalized objective functions allied to MMSE. In sequence, the fuzzy MMSE approach is utilized to determine the optimal point of the multi-objective optimization. For sake of comparison, the performance of arc homotopy length, global criterion method, and weighted sums were explored. To illustrate this proposal, a multivariate case of AISI H13 hardened steel-turning process is used. Experimental results indicate that the solution found by NBI-MMSE approach is a more appropriate Pareto frontier that surpassed all the competitors and also provides the best-compromised solution to set the machine input parameters. Further, this algorithm was also tested in benchmark functions to confirm the NBI-MMSE efficiency.

Similar content being viewed by others

References

Gomes GF, de Almeida FA, da Silva Lopes Alexandrino P et al (2018) A multiobjective sensor placement optimization for SHM systems considering Fisher information matrix and mode shape interpolation. Eng Comput. https://doi.org/10.1007/s00366-018-0613-7

Gomes GF, de Almeida FA, da Cunha SS et al (2018) An estimate of the location of multiple delaminations on aeronautical CFRP plates using modal data inverse problem. Int J Adv Manuf Technol 99:1155. https://doi.org/10.1007/s00170-018-2502-z

Saghatforoush A, Monjezi M, Faradonbeh RS, Armaghani DJ (2018) Combination of neural network and ant colony optimization algorithms for prediction and optimization of flyrock and back–break induced by blasting. Eng Comput. https://doi.org/10.1007/s00366-015-0415-0

Chen XJ, Fu JP, Yao JL, Gan JF (2017) Prediction of shear strength for squat RC walls using a hybrid ANN–PSO model. Eng Comput. https://doi.org/10.1007/s00366-017-0547-5

Kaveh A, Zakian P, Improved (2017) GWO algorithm for optimal design of truss structures. Eng Comput. https://doi.org/10.1007/s00366-017-0567-1

MiarNaeimi F, Azizyan G, Rashki M (2017) Multi-level cross entropy optimizer (MCEO): an evolutionary optimization algorithm for engineering problems. Eng Comput. https://doi.org/10.1007/s00366-017-0569-z

Gomes GF, da Cunha SS, Ancelotti AC (2018) A sunflower optimization (SFO) algorithm applied to damage identification on laminated composite plates. Eng Comput. https://doi.org/10.1007/s00366-018-0620-8

Almeida F, Gomes G, De Paula V, Corrêa J, de Paiva A, Gomes J, Turrioni JA (2018) Weighted mean square error approach to the robust optimization of the surface roughness in an AISI 12L14 free-machining steel-turning process. Strojniški vestnik- J Mech Eng 64(3):147–156. https://doi.org/10.5545/sv-jme.2017.4901

Yang WP, Tarng YS (1998) Design optimization of cutting parameters for turning operations based on the Taguchi method. J Mater Process Technol 84(1–3):122–129. https://doi.org/10.1016/S0924-0136(98)00079-x

Chabbi A, Yallese MA, Nouioua M, Meddour I, Mabrouki T, Girardin F (2017) Modeling and optimization of turning process parameters during the cutting of polymer (POM C) based on RSM, ANN. and DF methods. Int J Adv Manuf Technol 91(5–8):2267–2290. https://doi.org/10.1007/s00170-016-9858-8

Almeida FA, De Paula TI, Leite RR, Gomes GF, Gomes JHF, Paiva AP, Balestrassi PP (2018) A multivariate GR&R approach to variability evaluation of measuring instruments in resistance spot welding process. J Manuf Process 36:465–479. https://doi.org/10.1016/j.jmapro.2018.10.030

Paiva AP, Paiva EJ, Ferreira JR, Balestrassi PP, Costa SC (2009) A multivariate mean square error optimization of AISI 52100 hardened steel turning. Int J Adv Manuf Technol 43:631–643. https://doi.org/10.1007/s00170-008-1745-5

Diez M, Campana EF, Stern F (2015) Design-space dimensionality reduction in shape optimization by Karhunen-Loève expansion. Comput Methods Appl Mech Eng 283:1525–1544. https://doi.org/10.1016/j.cma.2014.10.042

Daniel M, Arroyo M (2013) Nonlinear manifold learning for model reduction in finite elastodynamics, Comput Methods Appl Mech Eng 261–262:118–131. https://doi.org/10.1016/j.cma.2013.04.007

McFarland J, Mahadevan S (2008) Error and variability characterization in structural dynamics modeling. Comput Methods Appl Mech Eng 197:2621–2631. https://doi.org/10.1016/j.cma.2007.07.029

Jia G, Taflanidis AA (2013) Kriging metamodeling for approximation of high-dimensional wave and surge responses in real-time storm/hurricane risk assessment, Comput Methods Appl Mech Eng 261–262:24–38. https://doi.org/10.1016/j.cma.2013.03.012

Salah B, Zoheir M, Slimane Z, Jurgen B (2015) Inferential sensor-based adaptive principal components analysis of mould bath level for breakout defect detection and evaluation in continuous casting. Appl Soft Comput 34:120–128

Das I, Dennis JE (1998) Normal-Boundary Intersection: a new method for generating the Pareto surface in nonlinear multicriteria optimization problems. Soc Ind Appl Math 8:631–657. https://doi.org/10.1137/S1052623496307510

Ahmadi A, Kaymanesh A, Siano P, Janghorbani M, Nezhad AE, Sarno D (2015) Evaluating the effectiveness of normal boundary intersection method for short-term environmental/economic hydrothermal self-scheduling. Electr Power Syst Res 123:192–204

Ahmadi A, Aghaei J, Shayanfar HA, Rabiee A (2012) Mixed integer programming of multiobjective hydro-thermal self scheduling. Appl Soft Comput 12:2137–2146

Aghaei J, Amjady N, Shayanfar HA (2011) Multi-objective electricity market clearing considering dynamic security by lexicographic optimization and augmented epsilon constraint method. Appl Soft Comput 11:3846–3858

Yildiz AR (2012) A comparative study of population-based optimization algorithms for turning operations. Inf Sci 210:81–88

Yildiz AR (2013) Optimization of cutting parameters in multi-pass turning using artificial bee colony-based approach. Inf Sci 220:399–407

Mia M, Dhar NR (2016) Optimization of surface roughness and cutting temperature in high-pressure coolant-assisted hard turning using Taguchi method, Int J Adv Manuf Technol. https://doi.org/10.1007/s00170-016-8810-2

Bouacha K, Yallese MA, Mabrouki T, Rigal JF (2010) Statistical analysis of surface roughness and cutting forces using response surface methodology in hard turning of AISI 52100 bearing steel with CBN tool. Int J Refract Metal Hard Mater 28:349–361. https://doi.org/10.1016/j.ijrmhm.2009.11.011

Montgomery DC (2012) Design and analysis of experiments, 5th edn. Wiley, New York

Rao SS (2009) Engineering optimization: theory and practice, 4 edn. Wiley, Upper Saddle River, p 840

Cosimo A, Cardona A, Idelsohn S (2014) Improving the k-compressibility of Hyper Reduced Order Models with moving sources: Applications to welding and phase change problems. Comput Methods Appl Mech Engr 274:237–263. https://doi.org/10.1016/j.cma.2014.02.011

Filho JM, Filho JMC, Paiva AP, Souza PVG, Tomasin (2016) S. A PCA-based approach for substation clustering for voltage sag studies in the Brazilian new energy context. Electr Power Syst Res 136:31–42. https://doi.org/10.1016/j.epsr.2016.02.012

Hurtado JE, Alvarez DA (2012) The encounter of interval and probabilistic approaches to structural reliability at the design point, Comput Methods Appl Mech Eng 225–228:74–94. https://doi.org/10.1016/j.cma.2012.03.020

Johnson RA, Wichern DA (2007) Applied multivariate statistical analysis, 6th edn. PEARSON, Prentice-Hall Inc., Upper Saddle River, p 773

Subasi A, Sahin B, Kaymaz I (2016) Multi-objective optimization of a honeycomb heat sink using response surface method. Int J Heat Mass Transf 101:295–302. https://doi.org/10.1016/j.ijheatmasstransfer.2016.05.012

Qu X, Liu G, Duan S, Yang J (2016) Multi-objective robust optimization method for the modified epoxy resin sheet molding compounds of the impeller. J Comput Des Eng 3:179–190. https://doi.org/10.1016/j.jcde.2016.01.002

Li Y, Liu G, Liu X, Liao S (2016) Thermodynamic multi-objective optimization of a solar-dish Brayton system based on maximum power output, thermal efficiency and ecological performance. Renew Energy 95:465–473. https://doi.org/10.1016/j.renene.2016.04.052

Xu C, Wu MZ, Hamdaoui M (2016) Mixed integer multi-objective optimization of composite structures with frequency-dependent interleaved viscoelastic damping layers. Comput Struct 172:81–92. https://doi.org/10.1016/j.compstruc.2016.05.006

Shukla PK, Deb (2007) K.On finding multiple Pareto-optimal solutions using classical and evolutionary generating methods. Eur J Oper Res 181:1630–1652. https://doi.org/10.1016/j.ejor.2006.08.002

Lopes LGD, Brito TG, Paiva AP, Peruchi RS, Balestrassi PP (2016) Robust parameter optimization based on multivariate normal boundary intersection. Comput Ind Eng 93:55–66. https://doi.org/10.1016/j.cie.2015.12.023

Brito TG, Paiva AP, Ferreira JR, Gomes JHF, Balestrassi PP (2014) A normal boundary interserction approach to multiresponse robust optimization of the surface roughness in end milling process with combined arrays. Precis Eng 38:628–638. https://doi.org/10.1016/j.precisioneng.2014.02.013

Box GEP, Hunter WG, Hunter JS (1978) Statistics for experiments. Wiley, New York

Montgomery DC (2013) Design and analysis of experiments, 8th edn. Wiley, New York

Cauchick-Miguel PA, Coppini NL (1996) Cost per piece determination in machining process: an alternative approach. Int J Mach Tools Manuf 36(8):939–946. https://doi.org/10.1016/0890-6955(96)00080-6

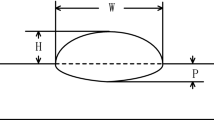

Campos PHS, Metodologia DEA-OTS (2015) Uma contribuição para a seleção ótima de ferramentas no Torneamento do Aço ABNT H13 Endurecido. Thesis, Federal University of Itajubá, Brazil

Newbold P (1994) Statistics for business & economics, 4th edn. Prentice Hall, Upper Saddle River

Köksoy O, Doganaksoy N (2003) Joint optimization of mean and standard deviation using response surface methods. J Qual Technol 35:239–252

Jamil M, Yang X (2013) A literature survey of benchmark functions for global optimisation problems. Int J Math Model Numerical Optim 4(2):150–194

Yao X, Liu Y, Lin G (1999) Evolutionary programming made faster. IEEE Trans Evol Comput 3(2):82–102

Vahidinasab V, Jadid S (2010) Normal boundary intersection method for suppliers’ strategic bidding in electricity markets: An environmental/economic approach. Energy Convers Manag 51:1111–1119. https://doi.org/10.1016/j.enconman.2009.12.019

Kim S, Kang K, Yoon K, Choi D (2016) Design optimization of an angular contact ball bearing for the main shaft of a grinder. Mech Mach Theory 104:287–302. https://doi.org/10.1016/j.mechmachtheory.2016.06.006

Islam S (2008) Multi-objective marketing planning inventory model: a geometric programming approach. Appl Math Comput 205:238–246. https://doi.org/10.1016/j.amc.2008.07.037

[Pereyra V Saunders M, Castillo J Equispaced Pareto front construction for constrained bi-objective optimization, Math Comput Model 57 (2013) 2122–2131. https://doi.org/10.1016/j.mcm.2010.12.044

Acknowledgements

The authors thanks the Brazilian financial support provided by CAPES (Fellow CAPES – Process nº 9801-12.0), CNPq (Process nº 303586/2015-0) and Prof. PhD. João Paulo Davim Tavares da Silva from the University of Aveiro, Portugal, who allowed and sponsored the consecution of experimental data set. The authors also express their gratitude to the anonymous reviewers who greatly contributed to article´s improvement with a large deal of suggestions.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Appendix A: applications of other optimization methods

Appendix A: applications of other optimization methods

1.1 Weighted sum (WSUM)

This approach is tested since the weighted sum is perhaps the most natural approach to the MOP which minimizes a convex combination of the different objectives [47]; but at the same time, has serious drawbacks such as its inability to find an equispaced Pareto frontier. Thereby, the best algorithm of optimization which results in the Pareto frontier shown in Fig. 9 will be reconstructed to check the robustness of the algorithm optimization proposed. Essentially, different weights are attributed in the scalarized Eqs. (25) and (26) to obtain a single objective optimization as represented by Eq. (39).

where \({w_i} \geq 0\)and \(\mathop \sum \nolimits_{{i=1}}^{n} {w_i}=0\). In sequence, the GRG algorithm is applied considering the objective functions in terms of MMSE and the experimental region constraint was the same as used in the NBI-MMSE approach of optimization. As a result, 21 optimum points are obtained as shown in Table 18 with the subsequent determination of the optimal point through the fuzzy decision maker.

1.2 Global criterion method (GCM)

Although the weighted sum method was popular due to its simplicity in implementation and usage to solve multi-objective problems, it could not reach the non-convex parts of the Pareto set. Therefore, as it is not known if the Pareto front a priori will be convex, the GCM is adopted which could reach the non-convex parts of the Pareto [48].

In this method, the distance between some reference points and the feasible objective regions is minimized. The decision maker has to select the reference point and the metric for measuring the distances [49]. In this way, the particular global criterion employed in this study was:

The next step is to conduct the GRG algorithm in Eq. (40) using the same objective functions in terms of MMSE and the experimental region constraint of NBI-MMSE approach of optimization. As a result, 21 optimum points are obtained as shown in Table 19 with the subsequent determination of the optimal point through the fuzzy decision maker.

1.3 Arc homotopic length (AHL)

The algorithm is based on convex combinations of the objectives and homotopic continuation. The scalar objective function is introduced as

where 0 ≤ w ≤ 1, and the same problem constraints apply. Standard homotopy starts at w = 0 and then steps w in some fashion, solving the successive problems to obtain a discrete sampling of the Pareto set and the Pareto front. A frequent criticism of this method is that there is no assured way to obtain a uniform sampling with it. because the parametrization of the Pareto front by w is usually a very nonlinear unknown map [50]. In the current method, the idea of intrinsic parametrization of the Pareto front using a discrete arc length was used.

Given a collection of points fk = f(xk), k = 0, 1, …, l + 1, the chord length of the polygon determined by these points was defined as \({S_l}=\sum\nolimits_{{k=0}}^{l} {\left\| {{f_{k+1}} - {f_k}} \right\|}\). Thus:

where the distance between the images of the minimizers times a factor α > 1 is an estimate of the total chord length of the Pareto front. Otherwise, γ ≠ 0 and it imposes the following equispaced constraint

where fprev is a previous point in the homotopy process. Then, the AHL formulation can be stated as the following matrix resolution where it minimizes the scalarized function, subject to all constraints with w as an additional variable.

Next, the GRG algorithm is conducted in the system of Eq. (44) using the same objective functions in terms of MMSE. As a result, Table 20 shows the 21 optimum points with the subsequent determination of the optimal point through the fuzzy decision maker.

Rights and permissions

About this article

Cite this article

Gaudêncio, J.H.D., de Almeida, F.A., Sabioni, R.C. et al. Fuzzy multivariate mean square error in equispaced pareto frontiers considering manufacturing process optimization problems. Engineering with Computers 35, 1213–1236 (2019). https://doi.org/10.1007/s00366-018-0660-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00366-018-0660-0