Abstract

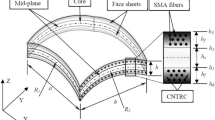

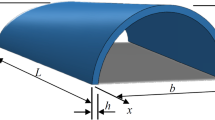

The vibration and damping characteristics of carbon nanotubes reinforced (CNTR) skewed shell structure under a hygrothermal environment have been investigated using the finite element method. CNT as reinforcing phase and polymer as matrix phase are considered for the nanocomposites (NCs) based viscoelastic skewed shell structure. Dynamic mechanical analysis is used to conduct the creep test for NCs samples which were fabricated, as per ASTM-D4065 standard, and obtained the viscoelastic properties in the frequency domain under different hygrothermal conditions. The shell geometry is defined by considering an arbitrary coordinate system for the skewed shell structure. Finite element modelling has been done with Serendipity element with five degrees of freedom in all eight nodes. The present formulation is based on Koiter’s shell theory and first-order shear deformation theory is considered to incorporate the transverse shear effect based on Mindlin’s hypothesis. The frequency dependant viscoelastic properties are directly used to obtain the frequency responses of the skewed shell panel using fast Fourier transform (FFT) whereas the transient responses are determined using inverse fast Fourier transform (IFFT). An in-house MATLAB code is developed for the numerical simulation and the accuracy of the proposed formulation is validated with available results in literatures and using ANSYS software. A parametric study has been carried out for the skewing angle and CNT volume fraction on the vibration behaviour of different thin and thick NC skewed shell structures under various hygrothermal conditions.

Similar content being viewed by others

References

Iijima S (1991) Helical microtubules of graphitic carbon. Nature 354(6348):56–58

Rajoria H, Jalili N (2005) Passive vibration damping enhancement using carbon nanotube-epoxy reinforced composites. Compos Sci Tech 65(14):2079–2093

Collings TA, Stone DEW (1985) Hygrothermal effects in CFC laminates: damaging effects of temperature, moisture and thermal spiking. Compos Struct 16:4

Gojny FH, Wichmann MHG, Kopke U (2004) Carbon nanotube-reinforced epoxy-composites—enhanced stiffness and fracture toughness at low nanotube contents. Compos Sci Tech 64(15):2363–2371

David AB (2004) Moisture diffusion in a fiber-reinforced composite: Part I – Non-Fickian transport and the effect of fiber spatial distribution. J Compos Mater 39, 23/2005

Lee CY, Pfeifer M, Thompson BS (1989) The characterization of elastic moduli and damping capacities of Graphite/Epoxy composite laminated beams in hygrothermal environments. J Compos Mater 23:819

Zhang YC, Wang X (2006) Hygrothermal effects on interfacial stress transfer characteristics of carbon nanotubes-reinforced composite system. J Reinf Plastic Compos 25, 1/2006

Nanda N, Pradyumna S (2011) Nonlinear dynamic response of laminated shells with imperfections in hygrothermal environments. J Compos Mater 45(20):2103–2112

Jia Y, Peng K, Gong X (2011) Creep and recovery of polypropylene/carbon nanotube composites. Int J Plastic 27(8):1239–1251

Tehrani M, Safdari M, Al-Haik MS (2011) Nano characterization of creep behaviour of multiwall carbon nanotubes/epoxy nanocomposite. Int J Plastic 27(6):887–901

Saseendran S, Berglund D, Varna J (2019) Stress relaxation and strain recovery phenomena during curing and thermomechanical loading: thermorheologically simple viscoelastic analysis. J Compos Mater 53(26–27):3841–3859

Jen YM, Huang C-Y (2013) Combined temperature and moisture effect on the strength of carbon nanotube reinforced epoxy materials. Trans Can Soc Mech Eng 37–3

Yizhuo G, Hongxin LML, Yanxia L (2014) Macro- and micro-interfacial properties of carbon fiber reinforced epoxy resin composite under hygrothermal treatments. J Reinf Plastic Compos 33(4):369–379

Garg M, Sharma S, Mehta R (2016) Carbon nanotube-reinforced glass fiber epoxy composite laminates exposed to hygrothermal conditioning. J Mater Sci 51:8562–8578

Burgarella B, Maurel-Pantel A, Moulinec H (2018) Effective viscoelastic behaviour of short fibers composites using virtual DMA experiments. Mech Time-Dep Mater 01806389

Hagenbeek M, Dias MM, Sinke J, Jansen K (2019) Creep behaviour of FM906 glass-fibre epoxy as used in heated fibre metal laminates. J Compos Mater 53(26–27):3829–3840

Khan SU, Li CY (2011) Siddiqui NA and Kim JK Vibration damping characteristics of carbon fiber-reinforced composites containing multi-walled carbon nanotubes. Compos Sci Technol 71(12):1486–1494. https://doi.org/10.1016/j.compscitech.2011.03.022

Patnaik SS, Roy T, Rao DK (2020) Numerical investigation of vibration characteristics and damping properties of CNT-based viscoelastic spherical shell structure. © Springer Nature Switzerland AG (2020) S. Oberst et al. (eds.), Vibration Engineering for a Sustainable Future, https://doi.org/10.1007/978-3-030-47618-2_29.

Patnaik SS, Swain A, Roy T (2020) Creep compliance and micromechanics of multi-walled carbon nanotubes based hybrid composites. Compos Mater Eng 2(2):141–162. https://doi.org/10.12989/cme.2020.2.2.141

Swain A, Roy T (2018) Viscoelastic modeling and vibration damping characteristics of hybrid CNTs-CFRP composite shell structures. Acta Mech 229:1321–1352. https://doi.org/10.1007/s00707-017-2051-9

Kiani Y (2017) Analysis of FG-CNT reinforced composite conical panel subjected to moving load using Ritz method. Thin-Walled Struct. https://doi.org/10.1016/j.tws.2017.05.031

Kiani Y (2017) Dynamics of FG-CNT reinforced composite cylindrical panel subjected to moving load. Thin-Walled Struct 111:48–57. https://doi.org/10.1016/j.tws.2016.11.011

Mahapatra TR (2016) Large amplitude vibration analysis of laminated composite spherical panels under hygrothermal environment. Int J Struct Stab Dyn. https://doi.org/10.1142/S0219455414501053

Kandasamy S, Singh AV (2006) Free vibration analysis of skewed open circular cylindrical shells. J Sound Vib. https://doi.org/10.1016/j.jsv.2005.05.010

Shojaee M, Setoodeh AR, Malekzadeh P (2017) Vibration of functionally graded CNTs reinforced skewed cylindrical panels using a transformed differential quadrature method. Acta Mech 228:2691–2711. https://doi.org/10.1007/s00707-017-1846-z

Biswal M, Sahu SK, Asha AV, Nanda M (2016) Hygrothermal effects on buckling of composite shell-experimental and FEM results. Steel Compos Struct 22(6):1445–1463. https://doi.org/10.12989/scs.2016.22.6.1445

Ebrahimi F, Dabbagh A (2019) An analytical solution for static stability of multi-scale hybrid nanocomposite plates. Eng Comput. https://doi.org/10.1007/s00366-019-00840-y

Ebrahimi F, Dabbagh A (2020) Vibration analysis of fluid-conveying multi-scale hybrid nanocomposite shells with respect to agglomeration of nanofillers. Def Technol. https://doi.org/10.1016/j.dt.2020.01.007

Roy T, Manikandan P, Chakraborty D (2010) Improved shell finite element for piezothermoelastic analysis of smart fiber reinforced composite structures. Finite Elements Anal Design. https://doi.org/10.1016/j.finel.2010.03.009

Sangtarash H, Arab HG, Sohrabi MR, Ghasemi MR (2019) Formulation and evaluation of a new four-node quadrilateral element for analysis of the shell structures. Eng Comput. https://doi.org/10.1007/s00366-019-00763-8

Mallek H, Jrad H, Wali M, Dammak F (2019) Nonlinear dynamic analysis of piezoelectric-bonded FG-CNTR composite structures using an improved FSDT theory. Eng Comput. https://doi.org/10.1007/s00366-019-00891-1

Sinha PK, Naidu NVS (2007) Nonlinear free vibration analysis of laminated composite shells in hygrothermal environments. Compos Struct 77(4):475–483

Biswal M, Sahu SK, Asha AV (2015) Experimental and numerical studies on free vibration of laminated composite shallow shells in hygrothermal environment. Compos Struct 127:165–174

Biswal M, Sahu SK, Asha AV (2016) Vibration of composite cylindrical shallow shells subjected to hygrothermal loading-experimental and numerical results. Compos Part B Eng 98:108–119

Karimiasl M, Ebrahimi F, Mahesh V (2019) Nonlinear free and forced vibration analysis of multiscale composite doubly curved shell embedded in shape-memory alloy fiber under hygrothermal environment. J Vib Control. https://doi.org/10.1177/1077546319842426

Tsai YI, Bosze EJ, Barjasteh E, Nutt SR (2009) Influence of hygrothermal environment on thermal and mechanical properties of carbon fiber/fiberglass hybrid composites. Compos Sci Technol 69(3–4):432–437

Kundalwal SI, Rathi A (2020) Improved mechanical and viscoelastic properties of CNT-composites fabricated using an innovative ultrasonic dual mixing technique. J Mech Behav Mater 29:77–85. https://doi.org/10.1515/jmbm-2020-0008

Kundalwal SI (2018) Review on micromechanics of nano- and micro-fiber reinforced composites. Polym Compos 39:4243–4274. https://doi.org/10.1002/pc.24569

Kundalwal SI, Suresh KR, Ray MC (2013) Smart damping of laminated fuzzy fiber reinforced composite shells using 1–3 piezoelectric composites. Smart Mater Struct. https://doi.org/10.1088/0964-1726/22/10/105001

Kundalwal SI, Ray MC (2016) Smart damping of fuzzy fiber reinforced composite plates using 1–3 piezoelectric composites. J Vib Control 22:1526–1546. https://doi.org/10.1177/1077546314543726

Ram KSS, Sinha PK (1992) Hygrothermal effects on the free vibration of laminated composite plates. J Sound Vib. https://doi.org/10.1016/0022-460X(92)90669-O

Cura F, Mura A, Scarpa F (2012) Modal strain energy based methods for the analysis of complex patterned free layer damped plates. J Vib Control 18:1291–1302. https://doi.org/10.1177/1077546311417277

Madeira JFA, Araújo AL, Soares CMM, Soares CAM, Ferreira AJM (2015) Multiobjective design of viscoelastic laminated composite sandwich panels. Compos B Eng 77:391–401. https://doi.org/10.1016/j.compositesb.2015.03.025

Rouleau L, Deü J-F, Legay A (2017) A comparison of model reduction techniques based on modal projection for structures with frequency-dependent damping. Mech Syst Signal Process 90:110–125. https://doi.org/10.1016/j.ymssp.2016.12.013

Barkanov E (1999) Transient response analysis of structures made from viscoelastic materials. Int J Num Methods Eng 44:393–403. https://doi.org/10.1002/(SICI)1097-0207(19990130)44:3%3c393,AID-NME511%3e3.0.CO;2-P

Sk L, Sinha PK (2005) Improved finite element analysis of multilayered doubly curved composite shells. J Reinf Plastics Compos. https://doi.org/10.1177/0731684405044899

Jarali CS, Patil SF, Pilli SC (2015) Hygro-thermo-electric properties of carbon nanotube epoxy nanocomposites with agglomeration effects. Mech Adv Mater Struct 22(6):428–439. https://doi.org/10.1080/15376494.2013.769654

Acknowledgements

The authors kindly acknowledged the IMPRINT cell of the Ministry of human resource development (MHRD) and the Department of science and technology (DST), Government of India, for a project grant (F. No. IMPRINT-6292) under which the research work was carried out.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author(s) declare that there are no potential conflicts of interest with respect to the research, authorship and/or publication of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

Shape functions (\({N}_{i}\)) used for the shell element are mentioned below:

Strain–displacement relation based on the Koiter shell theory

where, \(C_{0}=\frac{1}{2}\left(\frac{1}{R_1}-\frac{1}{R_2}\right)\).

The \(\rho\) matrix (symmetric) for the Eq. 53 is mentioned as:

The coefficient of thermal expansion and coefficient of moisture expansion terms for the Eq. 45 are mentioned as:

Rights and permissions

About this article

Cite this article

Patnaik, S.S., Roy, T. Vibration and damping characteristics of CNTR viscoelastic skewed shell structures under the influence of hygrothermal conditions. Engineering with Computers 38, 3773–3792 (2022). https://doi.org/10.1007/s00366-021-01411-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00366-021-01411-w