Abstract

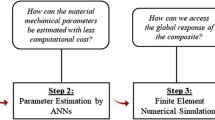

This paper presents a material optimization framework for identifying optimal material typologies to improve structural performance under the presence of uncertainties. Specifically, the focus in this work is on carbon nanotube (CNT)-reinforced concrete with the optimization problem consisting in finding the optimal CNT orientation in the host material so as to minimize the total deformation of structures made up from the composite. Regarding the material modeling, a two-level approach is considered to characterize the mechanical properties of the reinforced concrete. Specifically, cement mortar enhanced with carbon nanotubes is studied at a microscale level where a Drucker-Prager plasticity model is assumed to describe its inelastic behavior. Subsequently, the reinforced mortar along with the concrete’s larger aggregates is studied at a mesoscale level using continuum micromechanics. For the analysis of structural systems comprised of this composite material, an extension of the \(\hbox {FE}^{2}\) technique, termed \(\hbox {FE}^{3}\), is employed. To overcome the immense computational demands associated with \(\hbox {FE}^{3}\), efficient neural network-based surrogates are developed to approximate the nonlinear constitutive law of the composite. In this setting, the stochastic optimization problem equates to finding the optimal orientation of CNTs in the cement mortar, so as to achieve small structural deformations with low variability, under the presence of uncertainty in the loading conditions. To solve this problem, the Covariance Matrix Adaptation Evolution Strategy is chosen herein, and even though this approach requires a massive number of model runs, it is performed at a reasonable computational cost by virtue of the elaborated surrogate modeling scheme.

Similar content being viewed by others

References

Toutanji H, Delatte N, Aggoun S, Duval R, Danson A (2004) Effect of supplementary cementitious materials on the compressive strength and durability of short-term cured concrete. Cement Concr Res 34(2):311–319. https://doi.org/10.1016/j.cemconres.2003.08.017. https://www.sciencedirect.com/science/article/pii/S0008884603002953

Rejeb SK (1996) Improving compressive strength of concrete by a two-step mixing method. Cem Concr Res 26(4):585–592. https://doi.org/10.1016/0008-8846(96)00030-0. https://www.sciencedirect.com/science/article/pii/0008884696000300

Rodriguez-Camacho R, Uribe-Afif R (2002) Importance of using the natural pozzolans on concrete durability. Cem Concr Res32(12):1851–1858. https://doi.org/10.1016/S0008-8846(01)00714-1. https://www.sciencedirect.com/science/article/pii/S0008884601007141

Pacheco-Torgal F, Labrincha J (2013) Biotech cementitious materials: Some aspects of an innovative approach for concrete with enhanced durability. Constr Build Mater 40:1136–1141. https://doi.org/10.1016/j.conbuildmat.2012.09.080. https://www.sciencedirect.com/science/article/pii/S0950061812007581, special Section on Recycling Wastes for Use as Construction Materials

Graeff AG, Pilakoutas K, Neocleous K, Peres MVN (2012) Fatigue resistance and cracking mechanism of concrete pavements reinforced with recycled steel fibres recovered from post-consumer tyres. Eng Struct 45:385–395. https://doi.org/10.1016/j.engstruct.2012.06.030. https://www.sciencedirect.com/science/article/pii/S0141029612003392

Lee SJ, Rust JP, Hamouda H, Kim YR, Borden RH (2005) Fatigue cracking resistance of fiber-reinforced asphalt concrete. Text Res J 75(2):123–128. https://doi.org/10.1177/004051750507500206

Raza SS, Qureshi LA, Ali B, Raza A, Khan MM (2021) Effect of different fibers (steel fibers, glass fibers, and carbon fibers) on mechanical properties of reactive powder concrete. Struct Concr 22(1):334–346. https://doi.org/10.1002/suco.201900439. https://onlinelibrary.wiley.com/doi/abs/10.1002/suco.201900439

Tassew S, Lubell A (2014) Mechanical properties of glass fiber reinforced ceramic concrete. Constr Build Mater 51:215–224. https://doi.org/10.1016/j.conbuildmat.2013.10.046. https://www.sciencedirect.com/science/article/pii/S0950061813009677

Song P, Hwang S (2004) Mechanical properties of high-strength steel fiber-reinforced concrete. Constr Build Mater 18(9):669–673. https://doi.org/10.1016/j.conbuildmat.2004.04.027. https://www.sciencedirect.com/science/article/pii/S095006180400073X

Badogiannis EG, Sfikas IP, Voukia DV, Trezos KG, Tsivilis SG (2015) Durability of metakaolin self-compacting concrete. Constr Build Mater 82:133–141. https://doi.org/10.1016/j.conbuildmat.2015.02.023. https://www.sciencedirect.com/science/article/pii/S0950061815001701

Bjürnström J, Martinelli A, Matic A, Bürjesson L, Panas I (2004) Accelerating effects of colloidal nano-silica for beneficial calcium-silicate-hydrate formation in cement. Chem Phys Lett 392(1):242–248. https://doi.org/10.1016/j.cplett.2004.05.071. https://www.sciencedirect.com/science/article/pii/S0009261404007730

Jo BW, Kim CH, ho Tae G, Park JB, (2007) Characteristics of cement mortar with nano-sio2 particles. Constr Build Mater 21(6):1351–1355. https://doi.org/10.1016/j.conbuildmat.2005.12.020. https://www.sciencedirect.com/science/article/pii/S095006180600136X

Li H, Hua Zhang M, Ping Ou J (2007) Flexural fatigue performance of concrete containing nano-particles for pavement. Int J Fatigue 29(7):1292–1301. https://doi.org/10.1016/j.ijfatigue.2006.10.004. https://www.sciencedirect.com/science/article/pii/S0142112306002994

Li Z, Wang H, He S, Lu Y, Wang M (2006) Investigations on the preparation and mechanical properties of the nano-alumina reinforced cement composite. Mater Lett 60(3):356–359. https://doi.org/10.1016/j.matlet.2005.08.061. https://www.sciencedirect.com/science/article/pii/S0167577X05008463

Chang TP, Shih JY, Yang KM, Hsiao TC (2007) Material properties of portland cement paste with nano-montmorillonite. J Mater Sci 42(17):7478–7487. https://doi.org/10.1007/s10853-006-1462-0

Irshidat MR, Al-Saleh MH, Sanad SH (2015) Effect of nanoclay on expansive potential of cement mortar due to alkali-silica reaction. ACI Mater J 112:801–808

Li GY, Wang PM, Zhao X (2005) Mechanical behavior and microstructure of cement composites incorporating surface-treated multi-walled carbon nanotubes. Carbon 43(6):1239–1245. https://doi.org/10.1016/j.carbon.2004.12.017. https://www.sciencedirect.com/science/article/pii/S0008622305000199

Nochaiya T, Chaipanich A (2011) Behavior of multi-walled carbon nanotubes on the porosity and microstructure of cement-based materials. Appl Surf Sci 257(6):1941–1945. https://doi.org/10.1016/j.apsusc.2010.09.030. https://www.sciencedirect.com/science/article/pii/S0169433210012626

Xu S, Liu J, Li Q (2015) Mechanical properties and microstructure of multi-walled carbon nanotube-reinforced cement paste. Constr Build Mater 76:16–23. https://doi.org/10.1016/j.conbuildmat.2014.11.049. https://www.sciencedirect.com/science/article/pii/S0950061814012689

Treacy M, Ebbesen T, Gibson J (1996) Exceptionally high young’s modulus observed for individual carbon nanotubes. Nature 381(6584):678–680. https://doi.org/10.1038/381678a0

Berber S, Kwon YK, Tománek D (2000) Unusually high thermal conductivity of carbon nanotubes. Phys Rev Lett 84:4613–4616. https://doi.org/10.1103/PhysRevLett.84.4613. https://link.aps.org/doi/10.1103/PhysRevLett.84.4613

Ebbesen TW, Lezec HJ, Hiura H, Bennett JW, Ghaemi HF, Thio T (1996) Electrical conductivity of individual carbon nanotubes. Nature 382:54–56

Thostenson ET, Ren Z, Chou TW (2001) Advances in the science and technology of carbon nanotubes and their composites: a review. Compos Sci Technol 61(13):1899–1912. https://doi.org/10.1016/S0266-3538(01)00094-X. https://www.sciencedirect.com/science/article/pii/S026635380100094X

Mousavi MA, Sadeghi-Nik A, Bahari A, Jin C, Ahmed R, Ozbakkaloglu T, de Brito J (2021) Strength optimization of cementitious composites reinforced by carbon nanotubes and titania nanoparticles. Constr Build Mater 303(124):510. https://doi.org/10.1016/j.conbuildmat.2021.124510. https://www.sciencedirect.com/science/article/pii/S0950061821022662

Naji HF, Khalid NN, Alsaraj WK, Habouh MI, Marchetty S (2021) Experimental investigation of flexural enhancement of rc beams with multi-walled carbon nanotubes. Case Stud Constr Mater14(e00):480. https://doi.org/10.1016/j.cscm.2020.e00480. https://www.sciencedirect.com/science/article/pii/S2214509520301522

Alian A, El-Borgi S, Meguid S (2016) Multiscale modeling of the effect of waviness and agglomeration of cnts on the elastic properties of nanocomposites. Comput Mater Sci 117:195–204. https://doi.org/10.1016/j.commatsci.2016.01.029. https://www.sciencedirect.com/science/article/pii/S0927025616300027

Peng (2012) Modeling of nano-reinforced polymer composites: microstructure effect on young’s modulus. Comput Mater Sci 60:19–31. https://doi.org/10.1016/j.commatsci.2012.03.010

Parvin SA, Ahmed NA, Fattahi AM (2020) Numerical prediction of elastic properties for carbon nanotubes reinforced composites using a multi-scale method. Eng Comput pp 1–12

Wang J, Jivkov AP, Li Q, Engelberg DL (2020) Experimental and numerical investigation of mortar and itz parameters in meso-scale models of concrete. Theor Appl Fract Mech 109(102):722. https://doi.org/10.1016/j.tafmec.2020.102722. https://www.sciencedirect.com/science/article/pii/S0167844220302986

Feyel F (2003) A multilevel finite element method (fe2) to describe the response of highly non-linear structures using generalized continua. Comput Methods Appl Mech Eng 192(28):3233–3244

Schröder J (2014) A numerical two-scale homogenization scheme: the FE2-method, Springer, Vienna, pp 1–64. https://doi.org/10.1007/978-3-7091-1625-8_1

Erbatur F, Hasancebi O, Tutuncu I, Kilic H (2000) Optimal design of planar and space structures with genetic algorithms. Comput Struct 75(2):209–224. https://doi.org/10.1016/S0045-7949(99)00084-X. https://www.sciencedirect.com/science/article/pii/S004579499900084X

Ganzerli S, Pantelides CP, Reaveley LD (2000) Performance-based design using structural optimization. Earthq Eng Struct Dyn 29(11):1677–1690

Möller O, Foschi RO, Quiroz LM, Rubinstein M (2009) Structural optimization for performance-based design in earthquake engineering: Applications of neural networks. Struct Saf 31(6):490–499. https://doi.org/10.1016/j.strusafe.2009.06.007. https://www.sciencedirect.com/science/article/pii/S0167473009000551, optimization under Uncertainty with Emphasis on Structural Applications

Degertekin S, Tutar H, Lamberti L (2021) School-based optimization for performance-based optimum seismic design of steel frames. Eng Comput 37(4):3283–3297

Wang J, Zhang L, Liew K (2017) Multiscale simulation of mechanical properties and microstructure of cnt-reinforced cement-based composites. Comput Methods Appl Mech Eng 319:393–413. https://doi.org/10.1016/j.cma.2017.02.026. https://www.sciencedirect.com/science/article/pii/S0045782516318485

Hansen N, Kern S (2004) Evaluating the cma evolution strategy on multimodal test functions. In: Yao X, Burke EK, Lozano JA, Smith J, Merelo-Guervós JJ, Bullinaria JA, Rowe JE, Tiňo P, Kabán A, Schwefel HP (eds) Parallel Problem Solving from Nature - PPSN VIII. Springer, Berlin, pp 282–291

Hansen N (2006) The CMA evolution strategy: a comparing review. Springer, Berlin, pp 75–102. https://doi.org/10.1007/3-540-32494-1_4

Ba Anh L, Yvonnet J, He Q (2015) Computational homogenization of nonlinear elastic materials using neural networks: neural networks-based computational homogenization. Int J Numer Methods Eng 104

Lu X, Yvonnet J, Papadopoulos L, Kalogeris I, Papadopoulos V (2021) A stochastic fe2 data-driven method for nonlinear multiscale modeling. Materials 14(11). https://doi.org/10.3390/ma14112875. https://www.mdpi.com/1996-1944/14/11/2875

Liu X, Tian S, Tao F, Yu W (2021) A review of artificial neural networks in the constitutive modeling of composite materials. Compos Part B: Eng 224(109):152. https://doi.org/10.1016/j.compositesb.2021.109152. https://www.sciencedirect.com/science/article/pii/S1359836821005321

Wu L, Nguyen VD, Kilingar NG, Noels L (2020) A recurrent neural network-accelerated multi-scale model for elasto-plastic heterogeneous materials subjected to random cyclic and non-proportional loading paths. Computer Methods in Applied Mechanics and Engineering 369(113):234. https://doi.org/10.1016/j.cma.2020.113234https://www.sciencedirect.com/science/article/pii/S0045782520304199

Sorini A, Pineda EJ, Stuckner J, Gustafson PA (2021) A convolutional neural network for multiscale modeling of composite materials. AIAA Scitech 2021 Forum. https://doi.org/10.2514/6.2021-0310. https://arc.aiaa.org/doi/abs/10.2514/6.2021-0310

Sengodan GA (2021) Prediction of two-phase composite microstructure properties through deep learning of reduced dimensional structure-response data. Compos Part B: Eng 225(109):282. https://doi.org/10.1016/j.compositesb.2021.109282. https://www.sciencedirect.com/science/article/pii/S1359836821006582

Milad A, Hussein SH, Khekan A, Rashid M, Al-Masri H, Tran T (2021) Development of ensemble machine learning approaches for designing fiber-reinforced polymer composite strain prediction model. Eng Comput. https://doi.org/10.1007/s00366-021-01398-4

Pyrialakos S, Kalogeris I, Sotiropoulos G, Papadopoulos V (2021) A neural network-aided bayesian identification framework for multiscale modeling of nanocomposites. Comput Methods Appl Mech Eng 384(113):937. https://doi.org/10.1016/j.cma.2021.113937. https://www.sciencedirect.com/science/article/pii/S0045782521002747

Chen WH, Cheng HC, Liu YL (2010) Radial mechanical properties of single-walled carbon nanotubes using modified molecular structure mechanics. Comput Mater Sci 47(4):985–993

Savvas D, Papadopoulos V, Papadrakakis M (2012) The effect of interfacial shear strength on damping behavior of carbon nanotube reinforced composites. Int J Solids Struct 49(26):3823–3837

Savvas D, Papadopoulos V (2014) Nonlinear multiscale homogenization of carbon nanotube reinforced composites with interfacial slippage. Int J Multiscale Comput Eng 12(4):271–289

Feenstra PH, De Borst R (1996) A composite plasticity model for concrete. Int J Solids Struct 33(5):707–730

Vu G, Diewald F, Timothy JJ, Gehlen C, Meschke G (2021) Reduced order multiscale simulation of diffuse damage in concrete. Materials 14(14). https://doi.org/10.3390/ma14143830. https://www.mdpi.com/1996-1944/14/14/3830

Miehe C, Koch A (2002) Computational micro-to-macro transitions of discretized microstructures undergoing small strains. Arch Appl Mech 72:300–317

Geers M, Kouznetsova V, Brekelmans W (2010) Multi-scale computational homogenization: trends and challenges. J Comput Appl Math 234(7):2175–2182

Mei CC, Vernescu B (2010) Homogenization methods for multiscale mechanics. World Sci. https://doi.org/10.1142/7427. https://www.worldscientific.com/doi/abs/10.1142/7427

Baydin AG, Pearlmutter BA, Radul AA, Siskind JM (2017) Automatic differentiation in machine learning: a survey. J Mach Learn Res 18(1):5595–5637

Monteiro E, Yvonnet J, He Q (2008) Computational homogenization for nonlinear conduction in heterogeneous materials using model reduction. Comput Mater Sci 42(4):704–712. https://doi.org/10.1016/j.commatsci.2007.11.001

Mckay MD, Beckman RJ, Conover WJ (2000) A comparison of three methods for selecting values of input variables in the analysis of output from a computer code. Technometrics 42(1):55–61

Hansen N (2016) The CMA evolution strategy: a tutorial. arXiv:1604.00772

Marquardt DW (1963) An algorithm for least-squares estimation of nonlinear parameters. J Soc Ind Appl Math 11(2):431–441. http://www.jstor.org/stable/2098941

Acknowledgements

This research is co-financed by Greece and the European Union (European Social Fund- ESF) through the Operational Programme \(\ll \) Human Resources Development, Education and Lifelong Learning 2014–2020 \(\gg \) in the context of the project “Design of Hyperconcrete reinforced with nanomaterials” (MIS 5049082).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kalogeris, I., Pyrialakos, S., Kokkinos, O. et al. Stochastic optimization of carbon nanotube reinforced concrete for enhanced structural performance. Engineering with Computers 39, 2927–2943 (2023). https://doi.org/10.1007/s00366-022-01693-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00366-022-01693-8