Abstract

Within the modified couple stress elasticity, a novel nonconforming 3-node triangular plate element is derived from the d’Alembert–Lagrange principle for simulating the size-dependent static and dynamic bending behaviors of thin microplates and studying the effects of micro-inertia. This is accomplished via two main steps. First, the Trefftz functions that are derived from the governing equations of the problem concerned are adopted as the basis functions for constructing the element’s displacement interpolation. Second, according to the generalized conforming theory, the SemiLoof constraints are used to enforce the C1 compatibility requirement for guaranteeing the computation convergence. The benchmark tests are carried out and the results reveal that the new element exhibits satisfactory numerical accuracy and captures the size dependences effectively in the static, free vibration and forced vibration analyses. Moreover, the findings also show that the micro-inertia affects the dynamic response of the plate mainly through the natural frequency. In general, the influences on higher order modes are more obvious than that on lower order modes.

Similar content being viewed by others

Explore related subjects

Discover the latest articles and news from researchers in related subjects, suggested using machine learning.Data availability

Data are available on request from the authors.

References

Roudbari MA, Jorshari TD, Lü C, Ansari R, Kouzani AZ, Amabili M (2022) A review of size-dependent continuum mechanics models for micro- and nano-structures. Thin Wall Struct 170:108562

Fleck NA, Hutchinson JW (1993) A phenomenological theory for strain gradient effects in plasticity. J Mech Phys Solids 41(12):1825–1857

Altan BS, Aifantis EC (1997) On some aspects in the special theory of gradient elasticity. J Mech Behav Mater 8(3):231–282

Fleck NA, Muller GM, Ashby MF, Hutchinson JW (1994) Strain gradient plasticity: theory and experiment. Acta Metall Mater 42(2):475–487

Zozulya VV (2018) Higher order couple stress theory of plates and shells. ZAMM J Appl Math Mech/Zeitschrift für Angewandte Mathematik und Mechanik 98(10):1834–1863

Toupin RA (1962) Elastic materials with couple-stresses. Arch Ration Mech Anal 11(1):385–414

Mindlin RD, Tiersten HF (1962) Effects of couple-stresses in linear elasticity. Arch Ration Mech Anal 11(1):415–448

Eringen AC, Edelen DGB (1972) On nonlocal elasticity. Int J Eng Sci 10(3):233–248

Shaat M, Ghavanloo E, Fazelzadeh SA (2020) Review on nonlocal continuum mechanics: Physics, material applicability, and mathematics. Mech Mater 150:103587

Eringen AC (1972) Linear theory of nonlocal elasticity and dispersion of plane waves. Int J Eng Sci 10(5):425–435

Yang F, Chong ACM, Lam DCC, Tong P (2002) Couple stress based strain gradient theory for elasticity. Int J Solids Struct 39(10):2731–2743

Tsiatas GC (2009) A new Kirchhoff plate model based on a modified couple stress theory. Int J Solids Struct 46(13):2757–2764

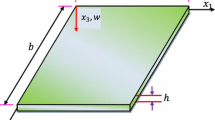

Tsiatas GC, Yiotis AJ (2015) Size effect on the static, dynamic and buckling analysis of orthotropic Kirchhoff-type skew micro-plates based on a modified couple stress theory: comparison with the nonlocal elasticity theory. Acta Mech 226(4):1267–1281

Wang YG, Lin WH, Zhou CL (2014) Nonlinear bending of size-dependent circular microplates based on the modified couple stress theory. Arch Appl Mech 84(3):391–400

Akgöz B, Civalek Ö (2013) Modeling and analysis of micro-sized plates resting on elastic medium using the modified couple stress theory. Meccanica 48(4):863–873

Zhang GY, Gao XL, Guo ZY (2017) A non-classical model for an orthotropic Kirchhoff plate embedded in a viscoelastic medium. Acta Mech 228(11):3811–3825

Rahaeifard M, Mojahedi M (2017) On the mechanics of laminated microplates. Int J Eng Sci 119:180–188

Kim J, Żur KK, Reddy JN (2019) Bending, free vibration, and buckling of modified couples stress-based functionally graded porous micro-plates. Compos Struct 209:879–888

Fang JS, Wang HW, Zhang XP (2019) On size-dependent dynamic behavior of rotating functionally graded Kirchhoff microplates. Int J Mech Sci 152:34–50

Farokhi H, Ghayesh MH, Gholipour A, Tavallaeinejad M (2018) Stability and nonlinear dynamical analysis of functionally graded microplates. Microsyst Technol 24(5):2109–2121

Kong SL (2021) A review on the size-dependent models of micro-beam and micro-plate based on the modified couple stress theory. Arch Comput Methods Eng 29(1):1–31

Thai HT, Vo TP, Nguyen TK, Kim SE (2017) A review of continuum mechanics models for size-dependent analysis of beams and plates. Compos Struct 177:196–219

Georgiadis HG, Velgaki EG (2003) High-frequency Rayleigh waves in materials with micro-structure and couple-stress effects. Int J Solids Struct 40(10):2501–2520

Wang CS, Zhang XK, Hu P (2016) A 4-node quasi-conforming quadrilateral element for couple stress theory immune to distorted mesh. Comput Struct 175:52–64

Choi JH, Lee BC (2018) A 3-node C0 triangular element for the modified couple stress theory based on the smoothed finite element method. Int J Numer Meth Eng 114(12):1245–1261

Kwon YR, Lee BC (2018) Three dimensional elements with Lagrange multipliers for the modified couple stress theory. Comput Mech 62(1):97–110

Shang Y, Li CF, Jia KY (2020) 8-node hexahedral unsymmetric element with rotation DOFs for modified couple stress elasticity. Int J Numer Meth Eng 121(12):2683–2700

Choi JH, Lee BC, Sim GD (2021) A 10-node tetrahedral element with condensed Lagrange multipliers for the modified couple stress theory. Comput Struct 246:106476

Ansari R, Shojaei MF, Mohammadi V, Bazdid-Vahdati M, Rouhi H (2015) Triangular Mindlin microplate element. Comput Methods Appl Mech Eng 295:56–76

Zhang B, He YM, Liu DB, Gan ZP, Shen L (2013) A non-classical Mindlin plate finite element based on a modified couple stress theory. Eur J Mech A Solids 42:63–80

Reddy JN, Romanoff J, Antonio Loya J (2016) Nonlinear finite element analysis of functionally graded circular plates with modified couple stress theory. Eur J Mech A/Solids 56:92–104

Soleimani I, Beni YT, Mehralian F (2018) A new size-dependent cylindrical shell element based on modified couple stress theory. Adv Appl Math Mech 10(4):819–844

Shang Y, Mao YH, Cen S, Li CF (2021) Generalized conforming Trefftz element for size-dependent analysis of thin microplates based on the modified couple stress theory. Eng Anal Boundary Elem 125:46–58

Teixeira de Freitas JA, Tiago C (2020) Hybrid-Trefftz stress elements for plate bending. Int J Numer Meth Eng 121(9):1946–1976

Long YQ, Cen S, Long ZF (2009) Advanced finite element method in structural engineering. Springer and Tsinghua University Press, Beijing

Hughes TJR, Cottrell JA, Bazilevs Y (2005) Isogeometric analysis: CAD, finite elements, NURBS, exact geometry and mesh refinement. Comput Methods Appl Mech Eng 194(39):4135–4195

Thai CH, Ferreira AJM, Tran TD, Phung-Van P (2020) A size-dependent quasi-3D isogeometric model for functionally graded graphene platelet-reinforced composite microplates based on the modified couple stress theory. Compos Struct 234:111695

Fan F, Xu YB, Sahmani S, Safaei B (2020) Modified couple stress-based geometrically nonlinear oscillations of porous functionally graded microplates using NURBS-based isogeometric approach. Comput Methods Appl Mech Eng 372:113400

Schulte J, Dittmann M, Eugster SR, Hesch S, Reinicke T, dell’Isola F, Hesch C (2020) Isogeometric analysis of fiber reinforced composites using Kirchhoff-Love shell elements. Comput Methods Appl Mech Eng 362:112845

Thanh CL, Tran LV, Vu-Huu T, Abdel-Wahab M (2019) The size-dependent thermal bending and buckling analyses of composite laminate microplate based on new modified couple stress theory and isogeometric analysis. Comput Methods Appl Mech Eng 350:337–361

Long ZF (1993) Two generalized conforming plate elements based on Semiloof constraints. Comput Struct 47(2):299–304

Akbarzadeh Khorshidi M, Soltani D (2020) Nanostructure-dependent dispersion of carbon nanostructures: new insights into the modified couple stress theory. Math Methods Appl Sci. https://doi.org/10.1002/mma.6748

Nobili A (2021) Asymptotically consistent size-dependent plate models based on the couple-stress theory with micro-inertia. Eur J Mech A Solids 89:104316

de Borst R, Sluys LJ (1991) Localisation in a Cosserat continuum under static and dynamic loading conditions. Comput Methods Appl Mech Eng 90(1):805–827

Pian THH, Sumihara K (1984) Hybrid Semiloof elements for plates and shells based upon a modified Hu–Washizu principle. Comput Struct 19(1):165–173

Chen YL, Cen S, Yao ZH, Long YQ, Long ZF (2003) Development of triangular flat-shell element using a new thin-thick plate bending element based on SemiLoof constrains. Struct Eng Mech 15(1):83–114

ABAQUS (2016) ABAQUS 2016 documentation Dassault systems, Providence

Xu Z, Zienkiewicz OC, Zeng LF (1994) Linked interpolation for reissner-mindlin plate elements. An alternative quadrilateral. Int J Numer Methods Eng 37(9):1437–1443

Cen S, Long YQ, Yao ZH, Chiew SP (2006) Application of the quadrilateral area co-ordinate method: a new element for Mindlin-Reissner plate. Int J Numer Meth Eng 66(1):1–45

Nguyen KD, Nguyen-Xuan H (2015) An isogeometric finite element approach for three-dimensional static and dynamic analysis of functionally graded material plate structures. Comput Struct 132:423–439

Askari AR, Tahani M (2015) Analytical determination of size-dependent natural frequencies of fully clamped rectangular microplates based on the modified couple stress theory. J Mech Sci Technol 29(5):2135–2145

Akgöz B, Civalek Ö (2012) Free vibration analysis for single-layered graphene sheets in an elastic matrix via modified couple stress theory. Mater Des 42:164–171

Wang YG, Lin WH, Liu N (2013) Large amplitude free vibration of size-dependent circular microplates based on the modified couple stress theory. Int J Mech Sci 71:51–57

Leissa AW (1969) “Vibration of Plates”, NASA SP-160. Scientific and Technical Information Division, Washington, DC

Acknowledgements

The work is financially supported by the National Natural Science Foundation of China (Grant numbers 12072154) and the Fundamental Research Funds for the Central Universities (ns2022006, xcxjh20210102).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors state that there is no potential conflict of interest in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix A

The detailed expression of the matrix \({\mathbf{U}}\) in Eq. (21) is

in which \(w_{i}^{0} ,\;\left( {i = 1\sim 12} \right)\) are the 12 functions given in Table 1, while \(\psi_{xi}^{0}\) and \(\psi_{yi}^{0}\) are the deduced plate rotations in accordance with Eq. (2).

Appendix B

The matrix \({{\varvec{\Lambda}}}\) in Eq. (30) takes the following form:

in which \({{\varvec{\Lambda}}}^{w}\) is given by

with

meanwhile \({{\varvec{\Lambda}}}^{\psi }\) is given by

with

Besides, the matrix \({{\varvec{\uplambda}}}\) in Eq. (30) can be calculated by

where \({{\varvec{\uplambda}}}^{w}\) is described as

and \({{\varvec{\uplambda}}}^{\psi }\) is determined by

with

Appendix C

The matrices \({\mathbf{N}}_{\theta }\), \({\mathbf{B}}_{\varepsilon }\) and \({\mathbf{B}}_{\chi }\) in Eq. (33) take the following forms, respectively:

where

in which the components of the matrices \({\mathbf{\rm M}}\), \({\mathbf{E}}\) and \({\mathbf{\rm X}}\) are calculated, respectively, by substituting the deflection \(w_{i}^{0} ,\;\left( {i = 1\sim 12} \right)\) listed in Table 1 into Eqs. (3) to (5).

Rights and permissions

About this article

Cite this article

Mao, YH., Shang, Y., Cen, S. et al. An efficient 3-node triangular plate element for static and dynamic analyses of microplates based on modified couple stress theory with micro-inertia. Engineering with Computers 39, 3061–3084 (2023). https://doi.org/10.1007/s00366-022-01715-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00366-022-01715-5

Keywords

Profiles

- Yan Shang View author profile