Abstract

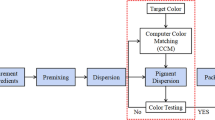

With the extensive application of machine vision in the manufacturing industry, target region recognition in complex industrial scenes is becoming a vital research territory. In the automatic polishing of molds, polishing red lead, as an auxiliary tool for polishing positioning, can intuitively determine the areas to be polished. Its bright color information are very suitable for vision-based recognition. Due to the interference of the near color in the polishing environment, the traditional color recognition method has the appearance of over-segmentation. In this paper, we propose a novel near-color recognition method via SVM based on threshold and feature transform (TFTSVM) to improve the identification accuracy of polishing red lead. Specifically, this method adopts a threshold-based color recognition algorithm to extract two kinds of color features of red lead color and its near color in HSV color space and skillfully finds it is distinguishable in three dimensions. To reduce the computational complexity, a machine learning segmentation model is constructed, which realizes dimension reduction by integrating the feature transformation method of sample transformation and projection transformation to achieve the best segmentation effect. Experimental results on self-established dataset demonstrate that the proposed method has an excellent identification effect on the red lead area in the field polishing environment and also shows good robustness under the condition that there are reflections on the mold surface. It meets the requirements of mechanical arm polishing and improves the safety and reliability of automatic polishing. In addition, we also compare different machine learning algorithms and advanced studies to verify the correctness of the algorithm. This method also provides a reference for realizing near-color recognition in complex industrial environments.

Similar content being viewed by others

References

Wu, B.H., Wang, J.J.J.: A neuro-fuzzy approach to generating mold/die polishing sequences. J. Mater. Process Technol. 209(7), 3241–3250 (2009). https://doi.org/10.1016/j.jmatprotec.2008.07.031

Wang, K., Dailami, F., Matthews, J.: Towards collaborative robotic polishing of mould and die sets. Procedia Manuf. 38, 1499–1507 (2019). https://doi.org/10.1016/j.promfg.2020.01.137

Xv, Z.Q., Wang, Q.L., Zhang, G.F., et al.: Controllable flexible surface polishing. Surf. Technol. 46(10), 99–107 (2017). https://doi.org/10.16490/j.cnki.issn.1001-3660.2017.10.014

Chang, G., Pan, R., Xie, Y., et al.: Research on constant force polishing method of curved mold based on position adaptive impedance control. Int. J. Adv. Manuf. Technol. 122(2), 697–709 (2022). https://doi.org/10.1007/s00170-022-09943-1

Zhang, H., Li, L., Zhao, J., et al.: Theoretical investigation and implementation of nonlinear material removal depth strategy for robot automatic grinding aviation blade. J. Manuf. Process. 74, 441–455 (2022). https://doi.org/10.1016/j.jmapro.2021.12.028

Segreto, T., Karam, S., Teti, R., et al.: Feature extraction and pattern recognition in acoustic emission monitoring of robot assisted polishing. Procedia CIRP. 28, 22–27 (2015). https://doi.org/10.1016/j.procir.2015.04.005

Segreto, T., Karam, S., Teti, R., et al.: Cognitive decision making in multiple sensor monitoring of robot assisted polishing. Procedia CIRP. 33, 333–338 (2015). https://doi.org/10.1016/j.procir.2015.06.075

Ferraguti, F., Pini, F., Gale, T., et al.: Augmented reality based approach for on-line quality assessment of polished surfaces. Rob. Comput. Integr. Manuf. 59, 158–167 (2019). https://doi.org/10.1016/j.rcim.2019.04.007

Long, K., Xie, Q., Lu, D., et al.: Aircraft skin gap and flush measurement based on seam region extraction from 3D point cloud. Measurement 176, 109169 (2021). https://doi.org/10.1016/j.measurement.2021.109169

Tang, W., He, F., Liu, Y.: YDTR: Infrared and visible image fusion via Y-shape dynamic transformer. IEEE Trans. Multimedia, pp. 1–16. IEEE (2022). https://doi.org/10.1109/TMM.2022.3192661

Zhang, S., He, F.: DRCDN: learning deep residual convolutional dehazing networks. Vis. Comput. 36(9), 1797–1808 (2020). https://doi.org/10.1007/s00371-019-01774-8

Amirkhani, A., Karimi, M.P., Banitalebi-Dehkordi, A.: A survey on adversarial attacks and defenses for object detection and their applications in autonomous vehicles. Vis. Comput. (2022). https://doi.org/10.1007/s00371-022-02660-6

Mou, T., Li, X.: Adaptive arc area inpainting and image enhancement method based on AI-DLC model. Vis. Comput. (2022). https://doi.org/10.1007/s00371-022-02718-5

Byrne, G., Sheahan, C.: Inline color vision for specific electroplating defect identification. J. Manuf. Process. 8(2), 133–143 (2006). https://doi.org/10.1016/S1526-6125(06)80008-3

Liu, Y.J., Zheng, Y.F., Lv, L., et al.: 3D model retrieval based on color + geometry signatures. Vis. Comput. 28(1), 75–86 (2012). https://doi.org/10.1007/s00371-011-0605-8

Ma, J., Lv, Q., Yan, H., et al.: Color-saliency-aware correlation filters with approximate affine transform for visual tracking. Vis. Comput. (2022). https://doi.org/10.1007/s00371-022-02573-4

Mehmet, S., Bülent, S.: Survey over image thresholding techniques and quantitative performance evaluation. J. Electron. Imaging. 13(1), 146–165 (2004). https://doi.org/10.1117/1.1631315

Upadhyay, P., Chhabra, J.K.: Kapur’s entropy based optimal multilevel image segmentation using Crow Search Algorithm. Appl. Soft Comput. 97, 105522 (2020). https://doi.org/10.1016/j.asoc.2019.105522

Chiu, C.-C.: A novel approach based on computerized image analysis for traditional Chinese medical diagnosis of the tongue. Comput. Methods Programs Biomed. 61(2), 77–89 (2000). https://doi.org/10.1016/S0169-2607(99)00031-0

Wang, Y.-G., Yang, J., Zhou, Y., et al.: Region partition and feature matching based color recognition of tongue image. Pattern Recognit. Lett. 28(1), 11–19 (2007). https://doi.org/10.1016/j.patrec.2006.06.004

Yin, Y., Shao, Y., Wang, K., et al.: Segmentation of workpiece surfaces with tool marks based on high definition metrology. J. Manuf. Process. 57, 268–287 (2020). https://doi.org/10.1016/j.jmapro.2020.06.035

Castillo-Martínez, M.Á., Gallegos-Funes, F.J., Carvajal-Gámez, B.E., et al.: Color index based thresholding method for background and foreground segmentation of plant images. Comput. Electron. Agric. 178, 105783 (2020). https://doi.org/10.1016/j.compag.2020.105783

Suh, H.K., Hofstee, J.W., van Henten, E.J.: Investigation on combinations of colour indices and threshold techniques in vegetation segmentation for volunteer potato control in sugar beet. Comput. Electron. Agric. 179, 105819 (2020). https://doi.org/10.1016/j.compag.2020.105819

Chouksey, M., Jha, R.K., Sharma, R.: A fast technique for image segmentation based on two Meta-heuristic algorithms. Multimed. Tools Appl. 79(27–28), 19075–19127 (2020). https://doi.org/10.1007/s11042-019-08138-3

Wang, N., Zhang, G., Ren, L., et al.: Vision and sound fusion-based material removal rate monitoring for abrasive belt grinding using improved LightGBM algorithm. J. Manuf. Process. 66, 281–292 (2021). https://doi.org/10.1016/j.jmapro.2021.04.014

Si, T., He, F., Zhang, Z., et al.: Hybrid contrastive learning for unsupervised person re-identification. IEEE Trans. Multim. IEEE (2022). https://doi.org/10.1109/TMM.2022.3174414

Fu, H., Ma, H., Wang, G., et al.: MCFF-CNN: Multiscale comprehensive feature fusion convolutional neural network for vehicle color recognition based on residual learning. Neurocomputing 395, 178–187 (2020). https://doi.org/10.1016/j.neucom.2018.02.111

Lei, L., Ke, C., Xiao, K., et al.: Identification of different bran-fried Atractylodis Rhizoma and prediction of atractylodin content based on multivariate data mining combined with intelligent color recognition and near-infrared spectroscopy. Spectrochim Acta A Mol. Biomol. Spectrosc. 262, 120119 (2021). https://doi.org/10.1016/j.saa.2021.120119

Zhang, H., Wang, X., Jiang, L., et al.: Near color recognition based on residual vector and SVM. Multimed. Tools Appl. 78(24), 35313–35328 (2019). https://doi.org/10.1007/s11042-019-08164-1

Malhotra, J., Jha, S.: Fuzzy c-means clustering based colour image segmentation for tool wear monitoring in micro-milling. Precision Eng. 72, 690–705 (2021). https://doi.org/10.1016/j.precisioneng.2021.07.013

Hanmandlu, M., Verma, O.P., Susan, S., et al.: Color segmentation by fuzzy co-clustering of chrominance color features. Neurocomputing 120, 235–249 (2013). https://doi.org/10.1016/j.neucom.2012.09.043

Yin, H., Yi, W., Hu, D.: Computer vision and machine learning applied in the mushroom industry: a critical review. Comput. Electron. Agric. 198, 107015 (2022). https://doi.org/10.1016/j.compag.2022.107015

Rafael, C.G., Richard, E.W.: Digital Image Processing, 3rd edn. Publishing House of Electronics Industry, Beijing (2017)

Penumuru, D.P., Muthuswamy, S., Karumbu, P.: Identification and classification of materials using machine vision and machine learning in the context of industry 4.0. J. Intell. Manuf. 31(5), 1229–1241 (2020). https://doi.org/10.1007/s10845-019-01508-6

Acknowledgements

This work was supported by the Sichuan Science and Technology Program (2021YFG0194).

Author information

Authors and Affiliations

Contributions

ZL contributed to Writing—Review & Editing, Project administration, Funding acquisition. XL contributed to Methodology, Validation, Writing—Original Draft. YH contributed to Resources, Writing—Review & Editing, Supervision.

Corresponding author

Ethics declarations

Competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liang, X., Luo, Z. & Han, Y. TFTSVM: near color recognition of polishing red lead via SVM based on threshold and feature transform. Vis Comput 40, 717–730 (2024). https://doi.org/10.1007/s00371-023-02811-3

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00371-023-02811-3