Abstract

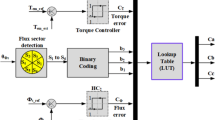

Choosing the appropriate control technique in variable speed drive (VSD) is very important to avoid faults on the hoisting system of molten metal. This paper analyzes the sensitivity of the hoist system in crane applications from the three various control techniques of variable speed drives of induction motors: V/f open-loop control, V/f closed-loop control and closed-loop vector control. It is noticed that stoppages of motor run are usually caused by the wrong selection of control technique, by overload (overcurrent and overvoltage) or by both. On the V/f control (open and closed-loop), when the load is 45 t in low output speed (5–6 Hz), the hook is moving without control downward direction, even if the command was given for lifting (upward direction), therefore we cannot use this control technique on the main hoist 50 T Crane. In the closed-loop vector control, the feedback error information determines the exact voltage vector position and norm to produce exactly what is needed to correct the error, as the result of the number of fault/trip on hoist crane applications will be minimal. For different loads, although the output currents change obviously, motor temperature remains constant.

Zusammenfassung

Die Wahl der geeigneten Regelungsstrategie bei drehzahlvariablen Antrieben ist sehr wichtig, um Schäden am Hebesystem an den geschweißten Verbindungen zu vermeiden. Diese Arbeit analysiert die Empfindlichkeit des Hubsystems bei Krananwendungen mit drei verschiedenen Regelungsverfahren von drehzahlvariablen Asynchronmaschinen: U/f-Regelung, U/f-Regelung mit offener Regelschleife sowie Regelung mit geschlossener Regelschleife. Man hat festgestellt, dass Stillstände des Motorlaufs in der Regel durch die falsche Auswahl der Regelstrategie, durch Überlastung (Überstrom und Überspannung) oder durch beides verursacht werden. Bei der U/f-Regelung (offen und geschlossen), wenn die Last 45 t bei niedriger Ausgangsdrehzahl (5–6 Hz) ist, bewegt sich der Haken ohne Regelung nach unten, auch wenn der Befehl zum Heben gegeben wurde (nach oben gerichtet), daher kann diese Regelungsstrategie nicht am Haupthubwerk mit 50 T verwendet werden. Bei der geschlossenen Vektorregelung bestimmt die Rückkopplungsfehlerinformation die exakte Spannungsvektorposition, um genau das zu generieren, was zur Korrektur des Fehlers erforderlich ist, damit die Anzahl der Fehler-/Auslösungen bei Hubkrananwendungen minimal wird. Für unterschiedliche Lasten, obwohl sich die Ausgangsströme offensichtlich ändern, bleibt die Motortemperatur konstant.

Similar content being viewed by others

References

Niapour, S. M., Garjan, G. S., Shafiei, M., Feyzi, M. R., Danyali, S., Kouhshahi, M. B. (2014): Review of permanent-magnet brushless DC motor basic drives based on analysis and simulation study. Int Rev. Electrical Eng., 9(5), 930–957. https://doi.org/10.15866/iree.v9i5.827.

Holopainen, T. P., Niiranen, J., Jörg, P., Andreo, D. (2013): Electric motors and drives in torsional vibration analysis and design. In Proceedings of the forty-second turbomachinery symposium, Houston, Texas.

Boldea, I. (2008): Control issues in adjustable speed drives. IEEE Ind. Electron. Mag., 2(3), 32–50. https://doi.org/10.1109/mie.2008.928605.

Saidur, R., Mekhilef, S., Ali, M. B., Safari, A., Mohammed, H. A. (2012): Applications of variable speed drive (VSD) in electrical motors energy savings. Renew. Sustain. Energy Rev., 16(1), 543–550. https://doi.org/10.1016/j.rser.2011.08.020.

Kabashi, Q., Limani, M., Caka, N., Zabeli, M. (2017): The impact of sampling frequency and amplitude modulation index on low order harmonics in a 3-phase SV-PVM voltage source inverter. Turk. J. Electr. Eng. Comput. Sci., 25(1), 184–199. https://doi.org/10.3906/elk-1408-34.

Kivelä, T., Markus, G. (2016): Simulation and analysis of an emergency lowering system for crane applications. Log. J. https://doi.org/10.2195/lj_proc_kivelae_en_201605_01.

Gaeid, K. S., Ping, H. W., Khalid, M., Masaoud, A. (2012): Sensor and sensorless fault tolerant control for induction motors using a wavelet index. Sensors, 12, 4031–4050. https://doi.org/10.3390/s120404031.

Yu, Z., Figoli, D. (1998): AC induction motor control using constant V/Hz principle and space vector PWM technique with TMS320c240. Application report. SPRA284A.

Akin, B., Garg, N. (2013): Scalar (V/f) control of 3-phase induction motors. Texas Instruments Application report. SPRABQ8.

Soni, S. K., Gupta, A. (2013): Analysis of SVPWM based speed control of induction motor drive with using V/F control based 3 level inverter. Int. J. Eng. Sci. Technol., 2(9), 932–938.

Peña, J. M., Díaz, E. V. (2016): Implementation of V/f scalar control for speed regulation of a three-phase induction motor. In IEEE conference proceedings, ANDESCON, Arequipa, Peru. https://doi.org/10.1109/andescon.2016.7836196.

Behera, P. K., Behera, M. K., Sahoo, A. K. (2014): Speed control of induction motor using scalar control technique. Int. J. Comput. Appl., 1, 37–39.

Peterson, S. (2014): Choosing the right control method for VFDs. Mach. Des., 86, 38.

Kiran, N. (2014): Indirect vector control of three phase induction motor using PSIM. Bull. Electr. Eng. Inform., 3, 15–24.doi. https://doi.org/10.11591/eei.v3i1.181.

Quang, N. P., Dittrich, J.-A. (2015): Vector Control of Three-Phase AC Machines: System Development in the Practice. 2nd ed. Berlin: Springer.

Trzynadlowski, A. M. (2001): Control of induction motors. San Diego: Academic Press.

Mitrovic, N., Petronijevic, M., Kostic, V., Jeftenic, B. (2012): Electrical drives for crane application. In M. Gokcek (Ed.), Mechanical Engineering. IntechOpen. https://doi.org/10.5772/35560.

Lepka, L., Stekl, P. (2005): 3-Phase AC induction motor vector control using a 56F80x, 6F8100 or 56F8300 device. Application note. Freescale semiconductor.

Siemens (2012): Simovert master drive vector control. User manual.

Author information

Authors and Affiliations

Corresponding author

Additional information

Q. Kabashi is the corresponding author of this paper.

Rights and permissions

About this article

Cite this article

Osmanaj, S., Simnica Aliu, K., Limani, M. et al. The sensitivity of the hoist system in crane applications from speed control methods at induction motor. Elektrotech. Inftech. 135, 195–203 (2018). https://doi.org/10.1007/s00502-018-0606-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00502-018-0606-7

Keywords

- induction motor

- variable speed drive

- crane hoist

- V/f open loop control

- V/f closed-loop control

- closed-loop vector control