Abstract

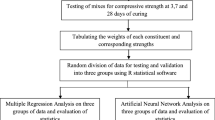

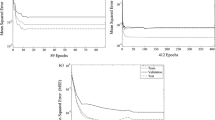

The present study aims at developing an artificial neural network (ANN) to predict the compressive strength of concrete. A data set containing a total of 72 concrete samples was used in the study. The following constituted the concrete mixture parameters: two distinct w/c ratios (0.63 and 0.70), three different types of cements and three different cure conditions. Measurement of compressive strengths was performed at 3, 7, 28 and 90 days. Two different ANN models were developed, one with 4 input and 1 output layers, 9 neurons and 1 hidden layer, and the other with 5, 6 neurons, 2 hidden layers. For the training of the developed models, 60 experimental data sets obtained prior to the process were used. The 12 experimental data not used in the training stage were utilized to test ANN models. The researchers have reached the conclusion that ANN provides a good alternative to the existing compressive strength prediction methods, where different cements, ages and cure conditions were used as input parameters.

Similar content being viewed by others

References

European Construction in Service of Society ECOserve NETWORK Cluster 2: production and application of blended cements. http://www.eco-serve.net/uploads/0032_Cluster2_argumentation_paper_final.pdf

Pipilikaki P, Katsioti M, Gallias JL (2009) Performance of limestone cement mortars in a high sulfates environment. Construct Build Mater 23:1042–1049

Kenai S, Soboyejo W, Soboyejo A (2004) Some engineering properties of limestone concrete. Mater Manuf Process 19(5):949–961

Gruskovnjak A, Lothenbach B, Winnefeld F, Figi R, Ko SC, Adler M, Mäder U (2008) Hydration mechanisms of super sulphated slag cement. Cement Concrete Res 38:983–992

Hadj-sadok A, Kenai S, Luc Courard, Darimont A (2011) Microstructure and durability of mortars modified with medium active blast furnace slag. Construct Build Mater 25:1018–1025

Rahhal V, Tolero R (2005) Early hydration of Portland cement with crystalline mineral additions. Cement Concrete Res 35(7):1285–1291

Bentz DP (2006) Modeling the influence of limestone filler on cement hydration using CEMHYD3D. Cement Concrete Compos 28(2):124–129

Dhir RK, Limbachiya MC, McCarthy MJ, Chaipanich A (2007) Evaluation of Portland limestone cements for use in concrete construction. Mater Struct 40(5):459–473

Lothenbach B, Le Saout G, Gallucci E, Scrivener K (2008) Influence of limestone on the hydration of Portland cements. Cement Concrete Res 38:848–860

Guemmadi Z, Houari H (2002) Influence de l’ajout de fines calcaires sur les performance des bétons dans l’Est Algérien. Annales du Bâtiment et des Travaux Publics 6:23–32

Bonavetti VL, Donza HA, Menendez G, Cabrera OA, Irassar EF (2003) Limestone filler cement in low w/c concrete a rational use of energy. Cement Concrete Res 33(6):865–871

Cyr M, Lawrence P, Ringot E (2006) Efficiency of mineral admixtures in mortars: quantification of the physical and chemical effects of fine admixtures in relation with compressive strength. Cement Concrete Res 36(2):264–277

Chidiac SE, Panesar DK (2008) Evolution of mechanical properties of concrete containing ground granulated blast furnace slag and effects on the scaling resistance test at 28 days. Cement Concrete Compos 30(2):63–71

Song HW, Saraswathy V (2006) Studies on the corrosion resistance of reinforced steel in concrete with ground granulated blast-furnace slag–an overview. J Hazard Mater 138(2):226–233

Ramezanianpour AA (1995) Effect of curing on the compressive strength, resistance to chloride-ion penetration and porosity of concrete incorporating slag, fly ash or silica fume. Cement Concrete Compos 80(1):125–133

Elmas Ç (2007) Yapay Zeka Uygulamaları. Seçkin Yayıncılık, Ankara (in Turkish)

Sarıdemir M (2009) Prediction of compressive strength of concretes containing metakaolin and silica fume by artificial neural networks. Adv Eng Softw 40:350–355

Lee SC (2003) Prediction of concrete strength using artificial neural networks. Eng Struct 25:849–857

Hertz J, Krogh A, Palmer R (1991) Introduction to the theory of neural networks. Addison-Wesley, Redwood City

Öztaş A (2006) Predicting the compressive strength and slump of high strength concrete using neural network. Construct Build Mater 20:769–775

Begg R (ed) (2006) Computational Intelligence for movement sciences: neural networks and other emerging techniques. Idea Group Publishing, Hershey, PA, p 220

Kewalramani AM, Gupta R (2006) Concrete compressive strength prediction using ultrasonic pulse velocity through artificial neural networks. Auto Constr 15(15):374–379

Demir F (2008) Prediction of elastic modulus of normal and high strength concrete by artificial neural networks. Construct Build Mater 22:1428–1435

Mansour MY, Dicleli M, Lee JY, Zhang J (2004) Predicting the shear strength of reinforced concrete beams using artificial neural network. Eng Struct 26(6):781–799

Yuhong Z, Wenxin H (2009) Application of artificial neural network to predict the friction factor of open channel flow. Commun Nonlinear Sci Numer Simulat 14:2373–2378

Topçu İB, Sarıdemir M (2007) Prediction of properties of waste AAC aggregate concrete using artificial neural network. Comput Mater Sci 41(1):117–125

Dombaycı ÖA, Gölcü M (2009) Daily means ambient temperature prediction using artificial neural network method: a case study of Turkey. Renew Energy 34:1158–1161

Alam S, Kaushik SC, Garg SN (2009) Assessment of diffuse solar energy under general sky condition using artificial neural network. Appl Energy 86:554–564

Keleşoğlu Ö (2008) Silis Dumanı Katkılı Betonların Çarpma Dayanımının Yapay Sinir Ağı ile Belirlenmesi. e-J New World Sci Acad 3(1):30–38 (in Turkish)

Smith K (ed) (2002) Neural networks in business: techniques and applications. Idea Group Publishing, Hershey, p 2

Tortum A, Yayla N, Çelik C, Gökdağ M (2007) The investigation of model selection criteria in artificial neural networks by the Taguchi method. Physica A 386:446–468

Lehmann EL, Casella G (1998) Theory of Point Estimation, 2nd edn. Springer, New York

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yaprak, H., Karacı, A. & Demir, İ. Prediction of the effect of varying cure conditions and w/c ratio on the compressive strength of concrete using artificial neural networks. Neural Comput & Applic 22, 133–141 (2013). https://doi.org/10.1007/s00521-011-0671-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00521-011-0671-x