Abstract

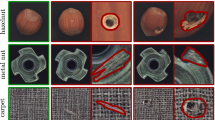

Optical inspection techniques have been widely used in industry as they are non-destructive. Since defect patterns are rooted from the manufacturing processes in semiconductor industry, efficient and effective defect detection and pattern recognition algorithms are in great demand to find out closely related causes. Modifying the manufacturing processes can eliminate defects, and thus to improve the yield. Defect patterns such as rings, semicircles, scratches, and clusters are the most common defects in the semiconductor industry. Conventional methods cannot identify two scale-variant or shift-variant or rotation-variant defect patterns, which in fact belong to the same failure causes. To address these problems, a new approach is proposed in this paper to detect these defect patterns in noisy images. First, a novel scheme is developed to simulate datasets of these 4 patterns for classifiers’ training and testing. Second, for real optical images, a series of image processing operations have been applied in the detection stage of our method. In the identification stage, defects are resized and then identified by the trained support vector machine. Adaptive resonance theory network 1 is also implemented for comparisons. Classification results of both simulated data and real noisy raw data show the effectiveness of our method.

Similar content being viewed by others

References

Chou PB, Rao AR, Struzenbecker MC, Wu FY, Brecher VH (1997) Automatic defect classification for semiconductor manufacturing. Mach Vis Appl 9(4):201–214

Cho H, Park WS (2002) Neural network applications in automated optical inspection: state of the arts, algorithms and systems for optical information processing VI. In: Javidi B, Psaltis D (eds) Proceedings of SPIE, vol 4789

Moganti M, Ercal F (1998) A subpattern level inspection system for printed circuit boards. Comput Vis Underst 70(1):51–62

Ken R, Brain S, Neil H (1991) Using full wafer defect maps as process signatures to monitor and control yield. IEEE/SEMI semiconductor manufacturing science symposium, pp 129–135

Chen FL, Liu SF (2000) A neural-network approach to recognize defect spatial pattern in semiconductor fabrication. IEEE Trans Semicond Manuf 13(3):366–373

Liu SF, Chen FL, Lu WB (2002) Wafer bin map recognition using a neural network approach. Int J Prod Res 40(10):2207–2223

Cunningam SP, MacKinnon S (1998) Statistical methods for visual defect methodology. IEEE Trans Semicond Manuf 11:48–53

Chien CF, Wang WC, Cheng JC (2007) Data mining for yield enhancement in semiconductor manufacturing and an empirical study. Expert Syst Appl 33(1):192–198

Hsieh HW, Chen FL (2004) Recognition of defect spatial patterns in semiconductor fabrication. Int J Prod Res 42(19):4153–4172

Wang CH, Wang SJ, Lee WD (2006) Automatic identification of spatial defect patterns for semiconductor manufacturing. Int J Prod Res 44(23):5169–5185

Jeong Y, Kim S, Jeong MK (2008) Automatic identification of defect patterns in semiconductor wafer maps using spatial correlogram and dynamic time warping. IEEE Trans Semicond Manuf 21(4):625–637

Gu N, Cao Z, Xie L, Tan M, Nahavandi S (2012) Identification of concurrent control chart patterns with singular spectrum analysis and learning vector quantization network. J Intell Manuf. doi:10.1007/s10845-012-0659-0

Hu J, Chen J, Sundararaman S, Chandrashekhara K (2009) Finite element analysis of V-ribbed belt/pulley system with pulley misalignment using a neural network based material model. Neural Comput Appl 18(8):927–938

Zhao D, Wang Y, Lin Z, Sheng S (2013) An effective quality assessment method for small scale resistance spot welding based on process parameters. NDT&E International. doi:10.1016/j.ndteint.2013.01.008

Wang Q, Cao C, Li M, Zu H (2013) A new model based on grey theory and neural network algorithm for evaluation of aids clinical trial. Adv Comput Math Appl 2(3):292–297

Su CT, Yang T, Ke CM (2002) A neural-network for semiconductor wafer post-sawing inspection. IEEE Trans Semicond Manuf 15:260–266

Huang CJ (2007) Clustered defect detection of high quality chips using self-supervised multilayer perceptron. Expert Syst Appl 33:996–1003

Lee JH, Yu SJ, Park SC (2001) A new intelligent SOFM-based sampling plan for advanced process control. Expert Syst Appl 20:133–151

DeNicolao G, Pasquinetti E, Miraglia G, Piccinini F (2003) Unsupervised spatial pattern classification of electrical failures in semiconductor manufacturing, workshop on Artificial Neural Networks in Pattern Recognition, pp 125–131

Palma F, DeNicolao G, Miraglia G, Pasquinetti E, Piccinini F (2005) Unsupervised spatial pattern classification of electrical-wafer-sorting maps in semiconductor manufacturing. Pattern Recogn Lett 26(12):1857–1865

Choi G, Kim SH, Ha C, Bae SJ (2012) Multi-step ART1 algorithm for recognition of defect patterns on semiconductor wafers. Int J Prod Res 50(12):3274–3287

Wang CH (2009) Separation of composite defect patterns on wafer bin map using support vector clustering. Expert Syst Appl I(2):2554–2561

Wang CH (2008) Recognition of semiconductor defect patterns using spatial filtering and spectral clustering. Expert Syst Appl 34(3):1914–1923

Burges CJC (1998) A tutorial on support vector machines for pattern recognition. Data Min Knowl Discovery 2(2):955–974

Xie L, Li D, Simske SJ (2011) Feature dimensionality reduction for example-based image super-resolution. J Pattern Recogn Res 2:130–139

Song H, Choi KK, Lee I, Zhao L, Lamb D (2013) Adaptive virtual support vector machine for the reliability analysis of high-dimensional problems. Struct Multidisciplinary Optim 47(4):479–491

Xie L, Gu N, Li D, Cao Z, Tan M, Nahavandi S (2013) Concurrent control chart patterns recognition with singular spectrum analysis and support vector machine. Comput Ind Eng 64(1):280–289

Li TS, Huang CL (2009) Defect spatial pattern recognition using a hybrid SOM–SVM approach in semiconductor manufacturing. Exp Syst Appl 36(1):374–385

Chao LC, Tong LI (2009) Wafer defect pattern recognition by multi-class support vector machines by using a novel defect cluster index. Exp Syst Appl 36(6):10158–10167

Platt JC, Shawe-Taylor J, Cristianini N (2000) Large Margin DAGs for Multiclass Classification. In: Solla SA, Leen TK, Muller KR (eds). MIT Press, pp 547–553

Weston J, Watkins C (1998) Multi-class support vector machines, Technical report CSD-TR-98-04

Gonzalez RC, Richard E (2001) Woods, digital image processing, 2nd edn. Prentice Hall, Englewood Cliffs

Xie L, Gu N, Cao Z, Li D (2013) A hybrid approach for multiple particle tracking microrhelogy. Int J Adv Robot Syst 10. doi: 10.5772/54364.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xie, L., Huang, R., Gu, N. et al. A novel defect detection and identification method in optical inspection. Neural Comput & Applic 24, 1953–1962 (2014). https://doi.org/10.1007/s00521-013-1442-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00521-013-1442-7