Abstract

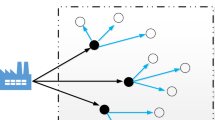

Distribution network planning has attracted the attention of many studies during last decades. Just-in-time (JIT) distribution has a key role in efficient delivery of products within distribution networks. In modeling of JIT distribution networks, the most frequently applied objectives are related to cost and service level. However, evaluating the impact of simultaneously minimizing total costs and balance between distribution network entities in different echelons still rarely complies with the current literature. To remedy this shortcoming and model reality more accurately, this paper develops a multi-objective mixed-integer nonlinear optimization model for a JIT distribution in three-echelon distribution network. The aims are minimization of total logistics cost along with maximization of capacity utilization balance for distribution centers and manufacturing plants. A non-dominated sorting genetic algorithm-II (NSGA-II) with three different mutation operators namely swap, reversion and insertion is employed to provide a set of near-optimal Pareto solutions. Then, the provided solutions are verified with non-dominated ranked genetic algorithm (NRGA) as well. The Taguchi method in design of experiments tunes the parameters of both algorithms, and their performances are then compared in terms of some multi-objective performance measures. In addition, a genetic algorithm is used to assess Pareto optimal solutions of NSGA-II. Different problems with different sizes are considered to compare the performance of the suggested algorithms. The results show that the proposed solution approach performs efficiently. Finally, the conclusion and some directions for future research are proposed.

Similar content being viewed by others

Explore related subjects

Discover the latest articles and news from researchers in related subjects, suggested using machine learning.References

Amiri A (2006) Designing a distribution network in a supply chain system: formulation and efficient solution procedure. Eur J Oper Res 171(2):567–576

Sadeghi J et al (2013) Optimizing a multi-vendor multi-retailer vendor managed inventory problem: two tuned meta-heuristic algorithms. Knowl Based Syst 50:159–170

Memari A, Rahim ARBA, Ahmad RB (2014) Production planning and inventory control in automotive supply chain networks. In: Ali M, Pan J-S, Chen S-M, Horng M-F (eds) Modern advances in applied intelligence. Springer, pp 430–439

Lalmazloumian M et al (2013) A robust optimization model for agile and build-to-order supply chain planning under uncertainties. Ann Oper Res. doi:10.1007/s10479-013-1421-5

Pasandideh SHR, Niaki STA, Asadi K (2015) Bi-objective optimization of a multi-product multi-period three-echelon supply chain problem under uncertain environments: NSGA-II and NRGA. Inf Sci 292:57–74

Memari A, Rahim ARA, Ahmad RB (2015) An integrated production-distribution planning in green supply chain: a multi-objective evolutionary approach. Procedia CIRP 26:700–705

Memari A, Rahim ARA, Ahmad R (2014) Multi-objective genetic algorithm in green just-in-time logistics. In: 2014 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM). IEEE

Sabri EH, Beamon BM (2000) A multi-objective approach to simultaneous strategic and operational planning in supply chain design. Omega 28(5):581–598

Chan FT, Chung S, Wadhwa S (2005) A hybrid genetic algorithm for production and distribution. Omega 33(4):345–355

Che Z, Chiang C-J (2010) A modified Pareto genetic algorithm for multi-objective build-to-order supply chain planning with product assembly. Adv Eng Softw 41(7):1011–1022

Nasiri GR, Zolfaghari R, Davoudpour H (2014) An integrated supply chain production–distribution planning with stochastic demands. Comput Ind Eng 77:35–45

Abbasian-Hosseini SA, Nikakhtar A, Ghoddousi P (2014) Verification of lean construction benefits through simulation modeling: a case study of bricklaying process. KSCE J Civ Eng 18(5):1248–1260

Nikakhtar A et al (2015) Application of lean construction principles to reduce construction process waste using computer simulation: a case study. Int J Serv Oper Manag 20(4):461–480

Wang W, Fung RY, Chai Y (2004) Approach of just-in-time distribution requirements planning for supply chain management. Int J Prod Econ 91(2):101–107

Farahani RZ, Elahipanah M (2008) A genetic algorithm to optimize the total cost and service level for just-in-time distribution in a supply chain. Int J Prod Econ 111(2):229–243

Ding H, Benyoucef L, Xie X (2009) Stochastic multi-objective production-distribution network design using simulation-based optimization. Int J Prod Res 47(2):479–505

Ghasimi SA, Ramli R, Saibani N (2014) A genetic algorithm for optimizing defective goods supply chain costs using JIT logistics and each-cycle lengths. Appl Math Model 38(4):1534–1547

Talbi E-G (2009) Metaheuristics: from design to implementation, vol 74. Wiley, Hoboken

Absi N et al (2016) A relax-and-repair heuristic for the Swap-Body Vehicle Routing Problem. Ann Oper Res. doi:10.1007/s10479-015-2098-8

Deb K et al (2000) A fast elitist non-dominated sorting genetic algorithm for multi-objective optimization: NSGA-II. In: Lecture notes in computer science, vol 1917, pp 849–858

Deb K (2001) Multi-objective optimization using evolutionary algorithms, vol 16. Wiley, Hoboken

Al Jadaan O, Rajamani L, Rao CR (2008) Non-dominated ranked genetic algorithm for solving multiobjective optimization problems: NRGA. J Theor Appl Inf Technol 2:60–67

Jayaraman V, Pirkul H (2001) Planning and coordination of production and distribution facilities for multiple commodities. Eur J Oper Res 133(2):394–408

Zarei M et al (2012).Identifying significant factors of brick laying process through design of experiment and computer simulation: a case study. In: Proceedings of World Academy of Science, Engineering and Technology. World Academy of Science, Engineering and Technology (WASET)

Taguchi G, Clausing D, Watanabe LT (1987) System of experimental design: engineering methods to optimize quality and minimize costs, vol 1. UNIPUB/Kraus International Publications White Plains, NY

Roy RK (1990) A primer on the Taguchi method. Society of Manufacturing Engineers, Dearborn

Taguchi G, Chowdhury S, Wu Y (2005) Taguchi’s quality engineering handbook. Wiley, Hoboken

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Memari, A., Abdul Rahim, A.R., Hassan, A. et al. A tuned NSGA-II to optimize the total cost and service level for a just-in-time distribution network. Neural Comput & Applic 28, 3413–3427 (2017). https://doi.org/10.1007/s00521-016-2249-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00521-016-2249-0