Abstract

Based on the traditional boring bar, a boring bar with friction damper is proposed in the paper. Firstly, the frequency response under different pressures is computed primarily based on the theory, which shows that the proposed boring bar has a certain vibration reduction effect. Secondly, the finite element model of the boring bar is built, and the first 6-order modes are computed, whose results are compared with the experimental value. As a result, the virtual reality of the boring bar is achieved. They are consistent with each other, which show that the finite element model is reliable. Then, the experimental cutting process of the boring bar is researched, which is compared with the simulation model with good coincidence. It is found from the result that the cutting simulation model of the boring bar is effective. Later, based on the verified simulation model, the positive pressure between the friction vibrator and boring bar, cutting speed, feed rate, back cutting depth and other parameters are changed to study the vibration reduction effects of the boring bar with friction damper. PSO (particle swarm optimization)-BP (backpropagation) neural network is then used to optimize the cutting process of the boring bar, and the optimal cutting parameters can be obtained. Finally, these optimized parameters are applied in the boring bar, the vibration reduction effect of the boring bar is verified by means of experiments, and the corresponding result shows that the proposed optimization in this paper is feasible. We can obtain higher quality work piece when we use this boring bar in the actual engineering.

Similar content being viewed by others

References

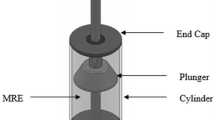

Mei D, Kong T, Shih AJ et al (2009) Magnetorheological fluid-controlled boring bar for chatter suppression. J Mater Process Technol 209(4):1861–1870

Moradi H, Bakhtiari-Nejad F, Movahhedy MR (2008) Tuneable vibration absorber design to suppress vibrations: an application in boring manufacturing process. J Sound Vib 318(1):93–108

Miguelez MH, Rubio L, Loya JA et al (2010) Improvement of chatter stability in boring operations with passive vibration absorbers. Int J Mech Sci 52(10):1376–1384

Sims ND (2007) Vibration absorbers for chatter suppression: a new analytical tuning methodology. J Sound Vib 301(3):592–607

Yao Z, Chen Z, Mei D (2011) Chatter suppression by parametric excitation: model and experiments. J Sound Vib 330(13):2995–3005

Andrén L, Håkansson L, Brandt A et al (2004) Identification of motion of cutting tool vibration in a continuous boring operation—correlation to structural properties. Mech Syst Signal Process 18(4):903–927

Zhai P, Zhang CR, Liu SY, Wang HT (2006) Dynamic design of a high frequency response servo bar used for boring. Manuf Technol Mach Tool 8:103–106

Mei D, Yao Z, Kong T et al (2010) Parameter optimization of time-varying stiffness method for chatter suppression based on magnetorheological fluid-controlled boring bar. Int J Adv Manuf Technol 46(9–12):1071–1083

Al-Wedyan HM, Bhat RB, Demirli K (2007) Whirling vibrations in boring trepanning association deep hole boring process: analytical and experimental investigations. J Manuf Sci Eng 129(1):48–62

Yi J, Wang Q, Zhao D et al (2007) BP neural network prediction-based variable-period sampling approach for networked control systems. Appl Math Comput 185(2):976–988

Zhang JH, Xie AG, Shen FM (2007) Multi-objective optimization and analysis model of sintering process based on BP neural network. J Iron Steel Res Int 14(2):1–5

Assarzadeh S, Ghoreishi M (2008) Neural-network-based modeling and optimization of the electro-discharge machining process. Int J Adv Manuf Technol 39(5–6):488–500

Park JB, Lee KS, Shin JR et al (2005) A particle swarm optimization for economic dispatch with nonsmooth cost functions. IEEE Trans Power Syst 20(1):34–42

Del Valle Y, Venayagamoorthy GK, Mohagheghi S et al (2008) Particle swarm optimization: basic concepts, variants and applications in power systems. IEEE Trans Evolut Comput 12(2):171–195

Jiang M, Luo YP, Yang SY (2007) Stochastic convergence analysis and parameter selection of the standard particle swarm optimization algorithm. Inf Process Lett 102(1):8–16

Chatterjee A, Siarry P (2006) Nonlinear inertia weight variation for dynamic adaptation in particle swarm optimization. Comput Oper Res 33(3):859–871

Khan K, Sahai A (2012) A comparison of BA, GA, PSO, BP and LM for training feed forward neural networks in e-learning context. Int J Intell Syst Appl 4(7):23

Ping W, Huang Z, Zhang M et al (2008) Mechanical property prediction of strip model based on PSO-BP neural network. J Iron Steel Res Int 15(3):87–91

Taormina R et al (2015) Data-driven input variable selection for rainfall-runoff modeling using binary-coded particle swarm optimization and Extreme Learning Machines. J Hydrol 529(3):1617–1632

Zhang J et al (2009) Multilayer ensemble pruning via novel multi-sub-swarm particle swarm optimization. J Univers Comput Sci 15(4):840–858

Wang WC et al (2015) Improving forecasting accuracy of annual runoff time series using ARIMA based on EEMD decomposition. Water Resour Manag 29(8):2655–2675

Zhang SW et al (2009) Dimension reduction using semi-supervised locally linear embedding for plant leaf classification. Lect Notes Comput Sci 5754:948–955

Wu CL et al (2009) Methods to improve neural network performance in daily flows prediction. J Hydrol 372(1–4):80–93

Chau KW et al (2010) A hybrid model coupled with singular spectrum analysis for daily rainfall prediction. J Hydroinform 12(4):458–473

Illias HA, Chai XR, Mokhlis H (2015) Transformer incipient fault prediction using combined artificial neural network and various particle swarm optimisation techniques. PLoS ONE 10(6):e0129363

Lv Z, Tek A, Da Silva F et al (2013) Game on, science-how video game technology may help biologists tackle visualization challenges. PLoS ONE 8(3):e57990

Wei W, Xu Q, Wang L et al (2014) GI/Geom/1 queue based on communication model for mesh networks. Int J Commun Syst 27(11):3013–3029

Lv Z, Chen G, Zhong C et al (2012) A framework for multi-dimensional webgis based interactive online virtual community. Adv Sci Lett 7(1):215–219

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

We declared that this manuscript has no any conflict of interest and was not submitted and published in the other journal, and it was only submitted to Neural Computing and Applications.

Rights and permissions

About this article

Cite this article

Sun, Ys., Zhang, Q. Optimization design and reality of the virtual cutting process for the boring bar based on PSO-BP neural networks. Neural Comput & Applic 29, 1357–1367 (2018). https://doi.org/10.1007/s00521-017-2904-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00521-017-2904-0