Abstract

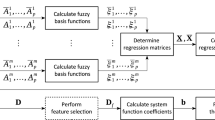

This paper addresses the fault detection and isolation problem in manufacturing systems. Some of these systems can be affected by several faults, a first way of determining them is to use classification and rule-based reasoning methods. In the present work, a new hybrid algorithm, based on fuzzy Levenberg–Marquardt and genetic algorithm for both training and fault isolation in the high-dimensional setting, is developed. The genetic algorithm-based approach aims at selecting an optimal number of production rules. The developed approach consists then to minimize training time and to find accurate and interpretable fuzzy systems with an appropriate production rules subset. It is put into practice for a real manufacturing system for binary classes and also its advantage is demonstrated on multi-class system. Obtained results show that the approach can be more accurate and fast to make fault diagnosis for binary and multi-class problems compared to those reported in the literature.

Similar content being viewed by others

References

Zhang Z, Wang Y, Wang K (2013) Intelligent fault diagnosis and prognosis approach for rotating machinery integrating wavelet transform, principal component analysis, and artificial neural networks. Int J Adv Manuf Technol 68:763–773

Isermann R (2011) Fault-diagnosis applications: model-based condition monitoring: actuators, drives, machinery, plants, sensors, and fault-tolerant systems. Springer, London

Kadri O, Mouss LH, Mouss MD (2012) Fault diagnosis of rotary kiln using SVM and binary ACO. J Mech Sci Technol 26:601–608

Wang H, Chen P (2009) Intelligent diagnosis method for a centrifugal pump using features of vibration signals. Neural Comput Appl 18:397–405

Li Y, Wang Z, Han X, Li Y (2009) High-voltage equipment condition monitoring and diagnosis system based on information fusion. Neural Comput Appl 18:447–453

Ertunc HM, Ocak H, Aliustaoglu C (2013) ANN- and ANFIS-based multi-staged decision algorithm for the detection and diagnosis of bearing faults. Neural Comput Appl 22(Suppl 1):435–446

Fouladirad M, Grall A (2013) Monitoring and condition-based maintenance with abrupt change in a system’s deterioration rate. Int J Syst Sci 46:2183–2194

Djelloul I, Souier M, Sari Z (2015) fault diagnosis problem integrated with condition based maintenance strategy. Electroteh Electron Autom (EEA) 63:102–109

Peng H, Wang J, Perez-Jimenez MJ, Wang H, Shao J, Wang T (2013) Fuzzy reasoning spiking neural P system for fault diagnosis. Inf Sci 235:106–116

Filippetti F, Franceschini G, Tassoni C (2000) Recent developments of induction motor drives fault diagnosis using AI techniques. IEEE Trans Ind Electron 47:994–1003

Ruano A, Cabrita C, Oliveira J, Tikk D, Koczy L (2001) Supervised training algorithms for b-spline neural networks and fuzzy systems. In: IFSA world congress and 20th NAFIPS international conference, vol 5, pp 2830–2835

Yong P, Guo-Hua L (2009) A fuzzy optimization neural network model using second order information. Fuzzy Syst Knowl Discov 4:221–227

Islam RU, Hossain MS, Andersson K (2016) A novel anomaly detection algorithm for sensor data under uncertainty. Soft Comput. doi:10.1007/s00500-016-2425-2

Wang X, Du H, Tan J (2016) Online fault diagnosis for biochemical process based on FCM and SVM. Interdiscip Sci Comput Life Sci. doi:10.1007/s12539-016-0172-9

Wang L, Chan CY (2012) Formulation of a novel production line monitoring technique. Int J Prod Res 50:6612–6623

Zhou E, Khotanzad A (2007) Fuzzy classifier design using genetic algorithms. Pattern Recogn 40:3401–3414

Ishibuchi H, Nozaki K, Yamamoto N, Tanaka H (1995) Selecting fuzzy if-then rules for classification problems using genetic algorithms. IEEE Trans Fuzzy Syst 3:260–270

Huang ML, Hung YH, Chen WY (2010) Neural network classifier with entropy based feature selection on breast cancer diagnosis. J Med Syst 34:865–873

Barani F, Mirhosseini M, Nezamabadi-Pour H (2017) Application of binary quantum-inspired gravitational search algorithm in feature subset selection. Appl Intell. doi:10.1007/s10489-017-0894-3

At-Kadi D, Simeu-Abazi Z, Arous A (2015) Fault isolation by test scheduling for embedded systems using a probabilistic approach. J Intell Manuf. doi:10.1007/s10845-015-1088-7

Holland JH (1992) Adaptation in natural and artificial systems: an introductory analysis with applications to biology, control and artificial intelligence. MIT Press, Cambridge

Sanghamitra B, Sankar KP (2007) Classification and learning using genetic algorithms: application in bioinformatics and web intelligence. Natural Computing Series, New Delhi

Ishibuchi H, Murata T, Turksen IB (1997) Single-objective and two objective genetic algorithms for selecting linguistic rules for pattern classification problems. Fuzzy Sets Syst 89:135–150

Ishibuchi H, Murata T (2004) Comparison of heuristic criteria for Fuzzy rule selection in classification problems. Fuzzy Optim Decis Making 3:119–139

Nojima Y, Ishibuchi H (2009) Incorporation of user preference into multi-objective genetic fuzzy rule selection for pattern classifi cation problems. Artif Life Robot 14:418–421

Alcalá R, Nojima Y, Herrera F, Ishibuchi H (2010) Multiobjective genetic fuzzy rule selection of single granularity-based fuzzy classification rules and its interaction with the lateral tuning of membership functions. Soft Comput. doi:10.1007/s00500-010-0671-2

Djelloul I, Souier M, Sari Z (2013) Neuro-fuzzy genetic algorithms for monitoring in a production system. In: IEEE international conference on systems and control, pp 12–17

Asuncion A, Newman DJ (2007) UCI machine learning repository. http://mlearn.ics.uci.edu/MLRepository.html

Acknowledgements

The authors would like to thank the referees for their valuable comments which helped to improve the manuscript.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

All authors declare that they have no conflict of interest.

Appendix: Bayes’ maximum likelihood formula

Appendix: Bayes’ maximum likelihood formula

Consider a set of n patterns of known classes \(\{x_{1}, x_{2},\ldots , x_{n},\}\) in N dimensional feature space, where it is assumed that each pattern corresponds to one of the possible classes.

We denote \(P_i\) as the priori probability, while \(p_i(x)\) is the class conditional density corresponding to the class \(C_i (i = 1, 2, \ldots , M)\). If the classifier decides x to be from the class \(C_i\), when it currently comes from unknown class (unknown fault) called \(C_l\), it incurs a loss equal to \(L_{li}\). The conditional average loss incurred in assigning a pattern x to the fault \(C_i\) is presented according to the following equation:

where \(P(C_{l}/x)\) gives the probability that pattern x is from \(C_l\). Based on the formula of Bayes, Eq. 19 can be expressed as:

where

For each dataset, the pattern x is affected to the class with the minimum probability of misclassification.

Rights and permissions

About this article

Cite this article

Djelloul, I., Sari, Z. & Souier, M. Fault isolation in manufacturing systems based on learning algorithm and fuzzy rule selection. Neural Comput & Applic 31, 3211–3225 (2019). https://doi.org/10.1007/s00521-017-3169-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00521-017-3169-3