Abstract

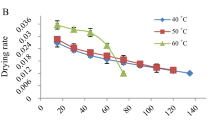

The application of artificial neural networks (ANN) in the freeze-drying of button mushrooms has been investigated. Networks with a single hidden layer, different training algorithms and complexity in terms of the number of neurons were evaluated for identifying the best ANN infrastructure. Moisture content, moisture ratio and drying rate were taken as output drying parameters for which ANN models provided an overall correlation coefficient (R) of 0.994, 0.991 and 0.992, respectively. The predictive efficiency of ANN was compared to semi-empirical models. Coefficients for semi-empirical models of moisture ratio were determined. Logarithm model gave the best fit (R2 = 0.985) for moisture ratio prediction but with larger mean square error and lower correlation than ANN model. The study highlights that ANN models with low complexity can be developed to precisely predict drying behaviour of biological materials while providing comparable and even superior results to that obtained from available semi-empirical drying models.

Similar content being viewed by others

Abbreviations

- a, b, c, k, n, k 0, k 1, k 2 :

-

Model coefficients

- b j, b k :

-

Weight bias of jth and kth neuron

- d.b.:

-

Dry basis

- p :

-

Number of explanatory variables (excluding constants)

- y i :

-

Observed data

- \(\overline{{y_{1} }}\) :

-

Mean of observed data

- \(\widehat{{y_{1} }}\) :

-

Predicted data

- t :

-

Time

- v jk :

-

Weight of connection from jth neuron to kth neuron

- w ij :

-

Weight of connection from ith neuron to jth neuron

- w.b.:

-

Wet basis

- DR:

-

Drying rate

- H I j :

-

Input signal to jth neuron of hidden layer

- H O j :

-

Output signal from jth neuron of hidden layer

- M 0 :

-

Initial moisture content

- M e :

-

Equilibrium moisture content

- MR:

-

Moisture ratio

- M t :

-

Moisture content at time t

- N :

-

Sample size

- O I k :

-

Input signal to kth neuron of output layer

- O O k :

-

Output signal from kth neuron of output layer

- PDT:

-

Primary drying temperature

- R 2 :

-

Coefficient of determination

- R 2adj :

-

Adjusted coefficient of determination

- SDT:

-

Secondary drying temperature

- ST:

-

Sample thickness

- W f :

-

Bone dry sample weight

- W t :

-

Sample weight at time t

References

Argyropoulos D, Heindl A, Joachim M (2011) Assessment of convection, hot-air combined with microwave- vacuum and freeze-drying methods for mushrooms with regard to product quality. Int J Food Sci Technol 46:333–342. https://doi.org/10.1111/j.1365-2621.2010.02500.x

ASABE Standards 2007 S269.4. Cubes, pellets and crumbles—Definitions and methods for determining density, durability and moisture content. St. Joseph, Mich.: ASABE pp 5

Asnaashari M, Farhoosh R, Farahmandfar R (2016) Prediction of oxidation parameters of purified Kilka fish oil including gallic acid and methyl gallate by adaptive neuro-fuzzy inference system (ANFIS) and artificial neural network. J Sci Food Agric 96:4594–4602. https://doi.org/10.1002/jsfa.7677

Basheer IA, Hajmeer M (2016) Artificial neural networks: fundamentals, computing, design, and application. J Microbiol Methods 43:3–31. https://doi.org/10.1016/S0167-7012(00)00201-3

Dorofki M, Elshafie AH, Jaafar O, Karim OA, Mastura S (2012) Comparison of Artificial Neural Network transfer functions abilities to simulate extreme runoff data. In: International conference on environment, energy and biotechnology, IACSIT press, Singapore 33: 39–44

Dragoi EN, Curteanu S, Fissore D (2012) Freeze-drying modeling and monitoring using a new neuro-evolutive technique. Chem Eng Sci 72:195–204. https://doi.org/10.1016/j.ces.2012.01.021

Fellows P (2017) Food processing technology, 4th edn. Woodhead publications Ltd., England

Giri SK, Prasad S (2006) Modeling shrinkage and density changes during microwave-vacuum drying of button mushroom. Int J Food Prop 9:409–419. https://doi.org/10.1080/10942910600596472

Giri SK, Prasad S (2007) Drying kinetics and rehydration characteristics of microwave-vacuum and convective hot-air dried mushrooms. J Food Eng 78:512–521. https://doi.org/10.1016/j.jfoodeng.2005.10.021

Gomes V, Fernandes A, Martins-Lopes P, Periera L, Faia AM, Melo-Pinto P (2017) Characterization of neural network generalization in the determination of pH and anthocyanin content of wine grape in new vintages and varieties. Food Chem 218:40–46. https://doi.org/10.1016/j.foodchem.2016.09.024

Hernández-Pérez JA, Garcia-Alvarado MA, Trystram G, Heyd B (2002) Application of an artificial neural network for moisture transfer prediction considering shrinkage during drying of foodstuffs. In: Welti-Chanes J, Velez-Ruiz JF (eds) Transport phenomena in food processing. CRC Press, Florida, pp 183–196

Jafari SM, Ganje M, Dehnad D, Ghanbari V (2016) Mathematical, fuzzy logic and artificial neural network modeling techniques to predict drying kinetics of onion. J Food Process Pres 40:329–339. https://doi.org/10.1111/jfpp.12610

Jagadish LK, Krishnan VV, Shenbhagaraman R, Kaviyarasan V (2009) Comparitive study on the antioxidant, anticancer and antimicrobial property of Agaricus bisporus (J. E. Lange) Imbach before and after boiling. Afr J Biotechnol 8(4):654–661

Jena S, Sahoo A (2013) ANN modeling for diffusivity of mushroom and vegetables using a fluidized bed dryer. Particuology 11(5):607–613. https://doi.org/10.1016/j.partic.2012.07.015

Kulshreshtha M, Singh A, Deepti Vipul (2009) Effect of drying conditions on mushroom quality. J Eng Sci Technol 4:90–98

Liu J, Jiya L, Kan J, Jin C (2013) In vitro and in vivo antioxidant activity of ethanolic extact of white button mushroom (Agaricus bisporus). Food Chem Toxicol 51:310–316. https://doi.org/10.1016/j.fct.2012.10.014

Matilla P, Konko K, Eurola M, Pihlava JM, Astola J, Vahteristo L, Hietaniemi V, Kumpulainen J, Valtonen M, Piironen V (2001) Contents of vitamins, mineral elements, and some phenolic compounds in cultivated mushrooms. J Agric Food Chem 49:2343–2348. https://doi.org/10.1021/jf001525d

Menlik T, Kirmaci V, Usta H (2009) Modeling of freeze drying behaviours of strawberries by using artificial neural network. J Thermal Sci Technol 29(2):11–21

Menlik T, Kirmaci V, Usta H (2010) Determination of freeze-drying behaviours of apples using artificial neural network. Expert Syst Appl 37:7669–7677. https://doi.org/10.1016/j.eswa.2010.04.075

Onwude DI, Hashim N, Janius RB, Nawi NM, Abdan K (2016) Modeling the thin-layer drying of fruits and vegetables: a review. Compr Rev Food Sci Food Saf 15:599–618. https://doi.org/10.1111/1541-4337.12196

Pan L, Zhang Q, Zhang W, Sun Y, Hu P, Tu K (2016) Detection of cold injury in peaches by hyperspectral reflectance imaging and artificial neural network. Food Chem 192:134–141. https://doi.org/10.1016/j.foodchem.2015.06.106

Pei F, Shi Y, Mariga AM, Yang W, Tang X, Zhao L, An X, Hu Q (2014) Comparison of freeze-drying and freeze-drying combined with microwave vacuum drying methods on drying kinetics and rehydration characteristics of button mushroom (Agaricus bisporus) slices. Food Bioprocess Technol 7(6):1629–1639

Pikal MJ, Cardon S, Bhugra C, Jameel F, Rambhatla S, Mascarenhas WJ, Akay HU (2005) The non-steady state modeling of freeze drying: in-process product temperature and moisture content mapping and pharmaceutical product quality applications. Pharm Dev Technol 10(1):17–32. https://doi.org/10.1081/PDT-35869

Sadikoglu H, Liapis AI (1997) Mathematical modelling of the primary and secondary drying stages of bulk solution freeze-drying in trays: parameter estimation and model discrimination by comparison of theoretical results with experimental data. Dry Technol 15(3&4):791–810

Salehi F, Kashaninejad M, Jafarianlari A (2017) Drying kinetics and characteristics of combined infrared-vacuum drying of button mushroom slices. Heat Mass Transf 53(5):1751–1759. https://doi.org/10.1007/s00231-016-1931-1

Tarafdar A, Shahi NC, Singh A, Sirohi R (2017) Optimization of freeze-drying process parameters for qualitative evaluation of button mushroom (Agaricus bisporus) using response surface methodology. J Food Qual. https://doi.org/10.1155/2017/5043612

Tarafdar A, Shahi NC, Singh A, Sirohi R (2018) Artificial neural network modeling of water activity: a low energy approach to freeze drying. Food Bioprocess Technol 11:164–171. https://doi.org/10.1007/s11947-017-2002-4

Wang J, Yue H, Zhou Z (2017) An improved traceability system for food quality assurance and evaluation based on fuzzy classification and neural network. Food Control 79:363–370. https://doi.org/10.1016/j.foodcont.2017.04.013

Xu D, Wei L, Guangyue R, Wenchao L, Yunhong L (2015) Comparative study on the effects and efficiencies of three sublimation drying methods for mushrooms. Int J Agric Biol Eng 8(1):91–97. https://doi.org/10.3965/j.ijabe.20150801.012

Acknowledgements

The authors wish to thank Ms. Ranjna Sirohi, Mr. Mohd. Ishfaq Bhat, Mr. Anurag Kushwaha, Department of Post-Harvest Process and Food Engineering and Ms. Himani Joshi, College of Home Science, G.B. Pant University of Agriculture and Technology, Pantnagar, Uttarakhand, for their valuable assistance and suggestions for carrying out this study. The authors extend their gratitude to MRC, G.B. Pant University of Agriculture and Technology, Pantnagar, Uttarakhand, for growing and providing fresh button mushrooms for conducting the research work. Finally, the first author expresses admiration for the constant support of Ms. Ranjna Sirohi throughout the work and would like to ask her: Will you marry me?

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest.

Rights and permissions

About this article

Cite this article

Tarafdar, A., Shahi, N.C. & Singh, A. Freeze-drying behaviour prediction of button mushrooms using artificial neural network and comparison with semi-empirical models. Neural Comput & Applic 31, 7257–7268 (2019). https://doi.org/10.1007/s00521-018-3567-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00521-018-3567-1