Abstract

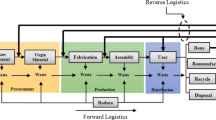

Considering the influence of carbon emissions trading, the fuzzy stochastic programming model was established to cut back the total cost of carbon trading balance. Modeling this chain is carried out by accounting for carbon cap-and-trade considerations and total cost optimization. In this paper, we analyze the low-carbon integrated forward/reverse logistics network and made relevant simulation tests. The results show that the changes of the confidence level and carbon emission limits have obvious influences on logistics costs. If the emission limit is large, carbon trading mechanism has little effect on the total logistics cost in the same scenario. Therefore, the government needs to use the appropriate emission limits to guide enterprises to reduce carbon emissions, and enterprises can make coping strategies according to the different limit at the same time. Therefore, the fuzzy random programming model proposed in this paper is practical. Its decision making applying the proposed algorithm is reasonable and applicable and could provide decision basis for enterprise managers.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.References

IPCC (2007) The physical science basis. Contribution of working group I to the fourth assessment report of the Intergovernmental Panel on Climate Change. Cambridge University Press, Cambridge

Carbon, Trust (2006) Carbon Footprint in the supply chain: the next step for business. Report No. CTC616, Carbon Trust London

Daskin MS, Benjaafar S (2010) National science foundation symposium on low carbon supply chain final. NSF Symposium report, USA

Guo J, Wang X, Fan S et al (2017) Forward and reverse logistics network and route planning under the environment of low-carbon emissions: a case study of shanghai fresh food E-commerce enterprises. Comput Ind Eng 106(C):351–360

Daryanto Y, Wee HM, Astanti RD (2019) Three-echelon supply chain model considering carbon emission and item deterioration. Transp Res Part E Logist Transp Rev 122:368–383

Wang J, Lim MK, Tseng M, Yang Y (2019) Promoting low carbon agenda in the urban logistics network distribution system. J Clean Prod 211:146–160

Jabbarzadeh A, Haughton M, Khosrojerdi A (2018) Closed-loop supply chain network design under disruption risks: a robust approach with real world application. Comput Ind Eng 116:178–191

Liao TY (2018) Reverse logistics network design for product recovery and remanufacturing. Appl Math Model 60:145–163

Schiffer M, Walther G (2018) Strategic planning of electric logistics fleet networks: a robust location-routing approach. Omega 80:31–42

Amin S, Ramezanian R (2018) An efficient hybrid genetic algorithm for multi-product competitive supply chain network design with price-dependent demand. Appl Soft Comput 71:872–893

Mahdi PM, Marjan O (2018) Designing and solving a reverse logistics network for polyethylene terephthalate bottles. J Clean Prod 195:605–617

Jing L, Zhong Y, Futao Z et al (2018) A novel method to solve supplier selection problem: hybrid algorithm of genetic algorithm and ant colony optimization. Math Comput Simul 156:294–309

Penkuhn T, Spengler T, Puchert H, Rentz O (1997) Environmental integrated production planning for ammonia synthesis. Eur J Oper Res 97(2):327–336

Cherrafi A, Garza-Reyes JA, Kumar V et al (2018) Lean, green practices and process innovation: a model for green supply chain performance. Int J Prod Econ 206:79–92

Mtalaa W, Aggoune R, Schaefers J (2009) CO2 emission calculation models for green supply chain management . http://coba.georgiasouthern.edu/hanna/FullPapers/Fullpaper.htm. Accessed 05 April 2010

Wong EYC, Tai AH, Emma Z (2018) Optimizing truckload operations in third-party logistics: a carbon footprint perspective in volatile supply chain. Transp Res Part D Transp Environ 63:649–661

Chen JX, Chen J (2017) Supply chain carbon foot printing and responsibility allocation under emission regulations. J Environ Manag 188:255–267

Zhang D, Zhan Q, Chen Y et al (2018) Joint optimization of logistics infrastructure investments and subsidies in a regional logistics network with CO2 emission reduction targets. Transp Res Part D Transp Environ 60:174–190

Ding H, Liu Q, Zheng L (2016) Assessing the economic performance of an environmental sustainable supply chain in reducing environmental externalities. Eur J Oper Res 255(2):463–480

Ding H, Zhao Q, An Z et al (2016) Collaborative mechanism of a sustainable supply chain with environmental constraints and carbon caps. Int J Prod Econ 181:191–207

Li F, Haasis HD (2017) Imposing emission trading scheme on supply chain: separate- and joint implementation. J Clean Prod 142:2288–2295

Bai Q, Gong Y, Jin M, Xu X (2019) Effects of carbon emission reduction on supply chain coordination with vendor-managed deteriorating product inventory. Int J Prod Econ 208:83–99

Mohan MN, Peter K (2019) Managing a dual-channel supply chain under price and delivery-time dependent stochastic demand. Eur J Oper Res 272(1):147–161

Xiao Z, Sun J, Shu W, Wang T (2019) Location-allocation problem of reverse logistics for end-of-life vehicles based on the measurement of carbon emissions. Comput Ind Eng 127:169–181

Zaid AA, Jaaron AAM, Abdul TB (2018) The impact of green human resource management and green supply chain management practices on sustainable performance: an empirical study. J Clean Prod 204:965–979

Ruiz-Benitez R, López C, Juan C, Real JC (2017) Environmental benefits of lean, green and resilient supply chain management: the case of the aerospace sector. J Clean Prod 167:850–862

Fahimnia B, Jabbarzadeh A, Sarkis J (2018) Greening versus resilience: a supply chain design perspective. Transp Res Part E Logist Transp Rev 119:129–148

Chang X, Xia H, Zhu H et al (2015) Production decisions in a hybrid manufacturing–remanufacturing system with carbon cap and trade mechanism. Int J Prod Econ 162:160–173

Lang X, Chuanxu W, Junjie Z (2018) Decision and coordination in the dual-channel supply chain considering cap-and-trade regulation. J Clean Prod 197:551–561

Comasmarti J, Tancrez JS, Seifert RW (2015) Carbon footprint and responsiveness trade-offs in supply chain network design. Int J Prod Econ 166:129–142

Abbassi A, Elhilali Alaoui A, Boukachour J (2019) Robust optimization of the intermodal freight transport problem: modeling and solving with an efficient hybrid approach. J Comput Sci 30:127–142

Asim Z, Jalil SA, Javaid S (2019) An uncertain model for integrated production-transportation closed-loop supply chain network with cost reliability. Sustain Prod Consum 17:298–310

Andres G, Laurence D, Nacima L et al (2018) A multi-population algorithm to solve the VRP with stochastic service and travel times. Comput Ind Eng 125:144–156

Langroodi RRP, Amiri M (2016) A system dynamics modeling approach for a multi-level, multi-product, multi-region supply chain under demand uncertainty. Expert Syst Appl 51:231–244

Noh J, Kim JS (2016) Cooperative green supply chain management with greenhouse gas emissions and fuzzy demand. J Clean Prod 208:1421–1435

He F, Yang J, Li M (2018) Vehicle scheduling under stochastic trip times: an approximate dynamic programming approach. Transp Res Part C Emerg Technol 96:144–159

Wei M, Chen X, Sun B, Zhu YY (2015) Model and algorithm for resolving regional bus scheduling problems with fuzzy travel times. J Intell Fuzzy Syst 29(6):2689–2696

Wang C, Matthies HG, Xu M et al (2018) Hybrid reliability analysis and optimization for spacecraft structural system with random and fuzzy parameters. Aerosp Sci Technol 77:353–361

John H (1992) Adaptation in natural and artificial systems. MIT Press, Cambridge

Khanduzi R, Sangaiah AK (2019) A fast genetic algorithm for a critical protection problem in biomedical supply chain networks. Appl Soft Comput 75:162–179

Senoussi A, Dauzère-Pérès S, Brahimi N et al (2018) Heuristics based on genetic algorithms for the capacitated multi vehicle production distribution problem. Comput Op Res 96:108–199

Cui YY, Guan Z, Saif U et al (2017) Close loop supply chain network problem with uncertainty in demand and returned products: genetic artificial bee colony algorithm approach. J Clean Prod 162:717–742

Woo YB, Kim BS (2018) A genetic algorithm-based metaheuristic for hydrogen supply chain network problem with two transportation modes and replenishment cycles. Comput Ind Eng (In press)

Mitsuo G, Lin L, Youngsu Y et al (2018) Recent advances in hybrid priority-based genetic algorithms for logistics and SCM network design. Comput Ind Eng 125:394–412

Dai Z, Aqlan F, Zheng X et al (2018) A location-inventory supply chain network model using two heuristic algorithms for perishable products with fuzzy constraints. Comput Ind Eng 119:338–352

Afrouzy ZA, Nasseri SH, Mahdavi I (2016) A genetic algorithm for supply chain configuration with new product development. Comput Ind Eng 101:440–454

Chakraborty D, Jana DK, Roy TK (2015) Multi-item integrated supply chain model for deteriorating items with stock dependent demand under fuzzy random and bifuzzy environments. Comput Ind Eng 88:166–180

Liu B (2001) Fuzzy random chance-constrained programming. IEEE Trans Fuzzy Syst 9(5):713–720

Ma Y, Yan F, Kang K et al (2016) A novel integrated production-distribution planning model with conflict and coordination in a supply chain network. Knowl-Based Syst 105:119–133

Acknowledgements

This research is supported by the National Nature Science Foundation of China (Project No: 71373157).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ren, Y., Wang, C., Li, B. et al. A genetic algorithm for fuzzy random and low-carbon integrated forward/reverse logistics network design. Neural Comput & Applic 32, 2005–2025 (2020). https://doi.org/10.1007/s00521-019-04340-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00521-019-04340-4