Abstract

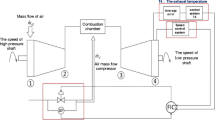

This research article corroborates the working of a model reference adaptive model (MRAS) with fractional-order proportional-integral (FOPI\(^\lambda \))-based encoderless speed control approach for ventilation system drive using recurrent neural network (RNN) for the low- and medium-range operation. The purpose of this study is to minimize the energy loss due to fluctuations and variation in the rotor speed and also find the optimum values of FOPI\(^\lambda \) by using a recurrent neural network to enhance the overall implementation of the system. In this perspective, the low-speed execution of MRAS is poor due to the existence of a pure integral and derivative parameter. Towards enhancement of the performance at speed region, a MRAS method with RNN is used. The network is trained using the Levenberg–Marquardt (LM) algorithm, and FOPI\(^\lambda \) control method is used for tuning the gain of proportional-integral of speed and current controller of the encoderless speed control of the ventilation drive. The presented RNN speed estimator with FOPI\(^\lambda \) controller has shown better performance and stability in transitory and stable operation as well as it also provides an enhancement in the overall efficiency of the ventilation drive. The validation of the presented algorithm is detailed experiments on a fully digitized 5.5 kW ventilation system using the Lab VIEW interface.

Similar content being viewed by others

References

Bose BK et al (2002) Modern power electronics and AC drives, vol 123. Prentice Hall Upper Saddle River, NJ

Ogasawara S, Akagi H, Nabae A (1988) The generalized theory of indirect vector control for AC machines. IEEE Trans Ind Appl 24(3):470–478

Peng F-Z, Fukao T (1994) Robust speed identification for speed-sensorless vector control of induction motors. IEEE Trans Ind Appl 30(5):1234–1240

Babu V, Maity T, Prasad H (2015) Energy saving techniques for ventilation fans used in underground coal mines—a survey. J. Min Sci 51(5):1001–1008

Vas P (1998) Sensorless vector and direct torque control. Oxford Univ Press, USA

Jafarzadeh S, Lascu C, Fadali MS (2012) Square root unscented kalman filters for state estimation of induction motor drives. IEEE Trans Ind Appl 49(1):92–99

Guo H, Chen H, Xu F, Wang F, Lu G (2012) Implementation of EKF for vehicle velocities estimation on FPGA. IEEE Trans Ind Electron 60(9):3823–3835

Roshany-Yamchi S, Cychowski M, Negenborn RR, De Schutter B, Delaney K, Connell J (2011) Kalman filter-based distributed predictive control of large-scale multi-rate systems: application to power networks. IEEE Trans Control Syst Technol 21(1):27–39

Demir R, Barut M (2018) Novel hybrid estimator based on model reference adaptive system and extended kalman filter for speed-sensorless induction motor control. Trans Inst Meas Control 40(13):3884–3898

Auger F, Hilairet M, Guerrero JM, Monmasson E, Orlowska-Kowalska T, Katsura S (2013) Industrial applications of the kalman filter: a review. IEEE Trans Ind Electron 60(12):5458–5471

Syamkumar U, Jayanand B (2020) Real-time implementation of sensorless indirect field-oriented control of three-phase induction motor using a kalman smoothing-based observer. Int Trans Electr Energy Syst 30(2):e12242

Wang H, Ge X, Liu Y-C (2018) Second-order sliding-mode mras observer-based sensorless vector control of linear induction motor drives for medium-low speed maglev applications. IEEE Trans Ind Electron 65(12):9938–9952

Salis V, Chiappinelli N, Costabeber A, Zanchetta P, Bifaretti S, Tomei P, Verrelli CM (2018) Learning position controls for hybrid step motors: from current-fed to full-order models. IEEE Trans Ind Electron 65(8):6120–6130

Harnefors L, Hinkkanen M (2013) Stabilization of sensorless induction motor drives: a survey. In: (2013) IEEE workshop on electrical machines design, control and diagnosis (WEMDCD), IEEE, pp 183–192

Chen B, Yao W, Chen F, Lu Z (2015) Parameter sensitivity in sensorless induction motor drives with the adaptive full-order observer. IEEE Trans Ind Electron 62(7):4307–4318

Orlowska-Kowalska T, Korzonek M, Tarchala G (2019) Stability improvement methods of adaptive full-order observer for sensorless induction motor drive—comparative study. IEEE Trans Ind Inf 15(11):6114–6126. https://doi.org/10.1109/TII.2019.2930465

Comanescu M (2016) Design and implementation of a highly robust sensorless sliding mode observer for the flux magnitude of the induction motor. IEEE Trans Energy Convers 31(2):649–657

Kommuri SK, Rath JJ, Veluvolu KC, Defoort M, Soh YC (2015) Decoupled current control and sensor fault detection with second-order sliding mode for induction motor. IET Control Theory Appl 9(4):608–617

Ammar A, Bourek A, Benakcha A (2017) Nonlinear SVM-DTC for induction motor drive using input–output feedback linearization and high order sliding mode control. ISA Trans 67:428–442

Ilten E, Demirtas M (2019) Fractional order super-twisting sliding mode observer for sensorless control of induction motor. COMPEL Int J Comput Math Electr Electron Eng 38(2):878–892

Cherifi D, Miloud Y (2019) Online stator and rotor resistance estimation scheme using sliding mode observer for indirect vector controlled speed sensorless induction motor. Am J Comput Sci Technol 2(1):1–8

Morawiec M, Lewicki A, Wilczyński F (2020) Speed observer of induction machine based on backstepping and sliding mode for low-speed operation. Asian J Control. https://doi.org/10.1002/asjc.2244

Schauder C (1992) Adaptive speed identification for vector control of induction motors without rotational transducers. IEEE Trans Ind Appl 28(5):1054–1061

Kumar R, Das S, Bhaumik A (2019) Speed sensorless model predictive current control of doubly-fed induction machine drive using model reference adaptive system. ISA Trans 86:215–226

Bahloul M, Vargas AN, Chrifi-Alaoui L, Drid S, Chaabane M (2019) Modified robust model reference adaptive system scheme for a speed sensorless vector control of induction motor. In: 2019 19th international conference on sciences and techniques of automatic control and computer engineering (STA), IEEE, pp 473–478

Korzonek M, Tarchala G, Orlowska-Kowalska T (2019) A review on MRAS-type speed estimators for reliable and efficient induction motor drives. ISA Trans 93:1–13

Tarchała G, Orłowska-Kowalska T (2018) Equivalent-signal-based sliding mode speed mras-type estimator for induction motor drive stable in the regenerating mode. IEEE Trans Ind Electron 65(9):6936–6947

Pal A, Das S (2020) Development of energy efficient scheme for speed sensorless induction motor drive. Int Trans Electr Energy Syst. https://doi.org/10.1002/2050-7038.12448

Kumar R, Das S, Syam P, Chattopadhyay AK (2015) Review on model reference adaptive system for sensorless vector control of induction motor drives. IET Electric Power Appl 9(7):496–511

Padmanaban S, Febin Daya JL, Blaabjerg F, Mir-Nasiri N, Ertas AH (2016) Numerical implementation of wavelet and fuzzy transform ifoc for three-phase induction motor. Eng Sci Technol Int J 19(1):96–100

Ali JA, Hannan M, Mohamed A, Abdolrasol MG (2016) Fuzzy logic speed controller optimization approach for induction motor drive using backtracking search algorithm. Measurement 78:49–62

Rao VV, Kumar AA (2018) Artificial neural network and adaptive neuro fuzzy control of direct torque control of induction motor for speed and torque ripple control. In: 2018 2nd international conference on trends in electronics and informatics (ICOEI), IEEE, pp 1416–1422

Sudheer H, Kodad S, Sarvesh B (2018) Improvements in direct torque control of induction motor for wide range of speed operation using fuzzy logic. J Electr Syst Inf Technol 5(3):813–828

Gopal BV, Shivakumar E (2019) Design and simulation of neuro-fuzzy controller for indirect vector-controlled induction motor drive. Data analytics and learning. Springer, Singapore, pp 155–167

Montero ER, Vogelsberger M, Fallmann F,Fahrner W, Wolbank TM (2018) Comparison of different signal processing methods for saliency-based sensorless control of induction machine using optimized excitation sequence. In: 2018 XIII international conference on electrical machines (ICEM), IEEE, pp 1413–1418

Montero ER, Vogelsberger M, Ertl H, Wolbank T, (2019) Combination of SVPWM switching states as transient excitation for saliency-based induction machine control. In: PCIM Europe, international exhibition and conference for power electronics, intelligent motion, renewable energy and energy management, VDE, pp 1–7

Chen J-Y, Yang S-C, Tu K-H (2018) Comparative evaluation of a permanent magnet machine saliency-based drive with sine-wave and square-wave voltage injection. Energies 11(9):2189

Metwaly MK, Elkalashy NI, Zaky MS, Wolbank TM (2017) Slotting saliency extraction for sensorless torque control of standard induction machines. IEEE Trans Energy Convers 33(1):68–77

Zhang Y, Yang H, Xia B (2016) Model-predictive control of induction motor drives: torque control versus flux control. IEEE Trans Ind Appl 52(5):4050–4060

Wang F, Zhang Z, Mei X, Rodríguez J, Kennel R (2018) Advanced control strategies of induction machine: field oriented control, direct torque control and model predictive control. Energies 11(1):120

Wang J, Wang F, Wang G, Li S, Yu L (2018) Generalized proportional integral observer based robust finite control set predictive current control for induction motor systems with time-varying disturbances. IEEE Trans Ind Inf 14(9):4159–4168

Rubino S, Bojoi R, Odhano SA, Zanchetta P (2018) Model predictive direct flux vector control of multi-three-phase induction motor drives. IEEE Trans Ind Appl 54(5):4394–4404

Celikel R, Gundogdu A (2020) System identification-based MPPT algorithm for PV systems under variable atmosphere conditions using current sensorless approach. Int Trans Electr Energy Syst 30(8):e12433

Kim S-H, Park T-S, Yoo J-Y, Park G-T (2001) Speed-sensorless vector control of an induction motor using neural network speed estimation. IEEE Trans Ind Electron 48(3):609–614

Morawiec M (2014) Z-type observer backstepping for induction machines. IEEE Trans Ind Electron 62(4):2090–2102

Vangipuram L et al (1990) Practical stability of nonlinear systems. World Scientific, Singapore

Narendra K, Valavani L (1980) A comparison of Lyapunov and hyperstability approaches to adaptive control of continuous systems. IEEE Trans Autom Control 25(2):243–247

Khan Y, Faraz N, Yildirim A, Wu Q (2011) Fractional variational iteration method for fractional initial-boundary value problems arising in the application of nonlinear science. Comput Math Appl 62(5):2273–2278

Khan Y, Wu Q, Faraz N, Yildirim A, Madani M (2012) A new fractional analytical approach via a modified Riemann–Liouville derivative. Appl Math Lett 25(10):1340–1346

Abdeljawad T (2015) On conformable fractional calculus. J Comput Appl Math 279:57–66

Morales-Delgado VF, Gómez-Aguilar JF, Yépez-Martínez H, Baleanu D, Escobar-Jimenez RF, Olivares-Peregrino VH (2016) Laplace homotopy analysis method for solving linear partial differential equations using a fractional derivative with and without kernel singular. Adv Differ Equ 2016(1):164

Khan Y, Fardi M, Sayevand K, Ghasemi M (2014) Solution of nonlinear fractional differential equations using an efficient approach. Neural Comput Appl 24(1):187–192

Baleanu D, Machado JAT, Luo AC (2011) Fractional dynamics and control. Springer, USA

Khan Y, Ali Beik SP, Sayevand K, Shayganmanesh A (2015) A numerical scheme for solving differential equations with space and time-fractional coordinate derivatives. Quaest Math 38(1):41–55

Khan Y, Faraz N, Smarda Z (2016) Difference kernel iterative method for linear and nonlinear partial differential equations. Neural Comput Appl 27(3):671–675

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

MOTOR PARAMETERS

Three-phase 5.5 kW 415-V, 50-Hz four-pole, star equivalent parameters are as follows: \(R_s = 0.7767\,\Omega \), \(R_r = 0.703\,\Omega ,\) \(L_s = 0.10773\) H, \(L_r = 0.10773\) H, \(L_m = 0.10322\) H, and \(J = 0.22\) kg\(\cdot \)m\(^2\).

Rights and permissions

About this article

Cite this article

Prince, Hati, A.S., Chakrabarti, P. et al. Development of energy efficient drive for ventilation system using recurrent neural network. Neural Comput & Applic 33, 8659–8668 (2021). https://doi.org/10.1007/s00521-020-05615-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00521-020-05615-x