Abstract

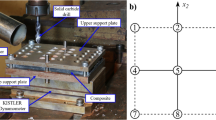

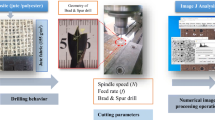

Biocomposites are increasingly being applied in the automotive industry. For assembly purpose, drilling process is often performed in these biocomposites parts to produce holes. The machining behavior of biocomposites is affected by the matrix, the reinforcements (nature and size), by the cutting conditions and the mechanical properties of biocomposites. Some of the newly developed biocomposites are made of a polypropylene/polyolefin blend matrix, which has low thermal conductivity and low softening temperature. Therefore, the selection of cutting parameters should be done with care to avoid thermal-induced damages occurred during drilling biocomposites. Also, due to the heterogeneous and anisotropic properties of biocomposites, it is essential to develop models for predicting the effects of these factors on the machining process performance indicators. In this research work, a full factorial design is used to investigate the effects of machining parameters (feed rate, drill diameter, spindle speed, and reinforcement type) on machinability indicators during the drilling of the three new biocomposites: Polypropylene/Polyolefin matrix reinforced with biocarbon particles and/or miscanthus fibers. The regression and ANFIS-based models are established for predicting thrust force (Ft) and surface roughness (Ra) based on empirical data. The results obtained show that, for each tested biocomposite, the proposed ANFIS models have better predictive accuracy for thrust force and surface roughness than the regression-based models. Furthermore, the drilling parameters and reinforcements used in these biocomposites considerably affect their machinability.

Similar content being viewed by others

Explore related subjects

Discover the latest articles and news from researchers in related subjects, suggested using machine learning.References

Koronis G, Silva A, Fontul M (2013) Erratum: green composites: a review of adequate materials for automotive applications (Composites Part B: Engineering (2013) 44 120–127) (Composites Part B: Engineering (2013) 47 391)). Compos Part B Eng, 49: 93. https://doi.org/10.1016/j.compositesb.2013.02.011

Peças P, Carvalho H, Salman H, Leite M (2018) Natural fibre composites and their applications: a review. J Compos Sci 2(4):66. https://doi.org/10.3390/jcs2040066

Nassar MMA, Arunachalam R, Alzebdeh KI (2017) Machinability of natural fiber reinforced composites: a review. Int J Adv Manuf Technol 88(9–12):2985–3004. https://doi.org/10.1007/s00170-016-9010-9

Tran DS et al (2020) Experimental investigation on machinability of polypropylene reinforced with miscanthus fibers and biochar. Materials. https://doi.org/10.3390/ma13051181

Abilash N, Sivapragash M (2016) Optimizing the delamination failure in bamboo fiber reinforced polyester composite. J King Saud Univ-Eng Sci 28(1):92–102. https://doi.org/10.1016/j.jksues.2013.09.004

Manickam R, Gopinath A (2017) Measurement and analysis of thrust force in drilling sisal-glass fiber reinforced polymer composites. IOP Conf Ser Mater Sci Eng. https://doi.org/10.1088/1757-899X/197/1/012056

Roy Choudhury M, Srinivas MS, Debnath K (2018) Experimental investigations on drilling of lignocellulosic fiber reinforced composite laminates. J Manuf Process 34:51–61. https://doi.org/10.1016/j.jmapro.2018.05.032

Rezghi Maleki H, Hamedi M, Kubouchi M, Arao Y (2019) Experimental study on drilling of jute fiber reinforced polymer composites. J Compos Mater 53(3):283–295. https://doi.org/10.1177/0021998318782376

Pailoor S, Murthy HNN, Sreenivasa TN (2019) Drilling of in-line compression molded Jute/Polypropylene composites. J Nat Fibers. https://doi.org/10.1080/15440478.2019.1612309

Tran DS, Songmene V, Ngo AD, Kouam J (2020) Effects of reinforcements and cutting parameters on machinability of polypropylene-based biocomposite reinforced with biocarbon particles and chopped miscanthus fibers. Int J Adv Manuf Technol. https://doi.org/10.1007/s00170-020-06070-7

Jayabal S, Natarajan U, Sekar U (2011) Regression modeling and optimization of machinability behavior of glass-coir-polyester hybrid composite using factorial design methodology. Int J Adv Manuf Technol 55(1–4):263–273. https://doi.org/10.1007/s00170-010-3030-7

Bajpai PK, Singh I (2013) Drilling behavior of sisal fiber-reinforced polypropylene composite laminates. J Reinf Plast Compos 32(20):1569–1576. https://doi.org/10.1177/0731684413492866

Mata F, Beamud E, Hanafi I, Khamlichi A, Jabbouri A, Bezzazi M (2010) Multiple regression prediction model for cutting forces in turning carbon-reinforced PEEK CF30. Adv Mater Sci Eng. https://doi.org/10.1155/2010/824098

Zain AM, Haron H, Sharif S (2010) Application of GA to optimize cutting conditions for minimizing surface roughness in end milling machining process. Expert Syst Appl 37(6):4650–4659. https://doi.org/10.1016/j.eswa.2009.12.043

Kumar R, Hynes NRJ (2019) Prediction and optimization of surface roughness in thermal drilling using integrated ANFIS and GA approach. Eng Sci Technol Int J 23:30–41. https://doi.org/10.1016/j.jestch.2019.04.011

Krishnaraj V et al (2012) Optimization of machining parameters at high speed drilling of carbon fiber reinforced plastic (CFRP) laminates. Compos Part B Eng 43(4):1791–1799. https://doi.org/10.1016/j.compositesb.2012.01.007

Subramanian M, Sakthivel M, Sooryaprakash K, Sudhakaran R (2013) Optimization of cutting parameters for cutting force in shoulder milling of Al7075-T6 using response surface methodology and genetic algorithm. Procedia Eng 64:690–700. https://doi.org/10.1016/j.proeng.2013.09.144

Karaboga D, Kaya E (2019) Adaptive network based fuzzy inference system (ANFIS) training approaches: a comprehensive survey. Artif Intell Rev 52(4):2263–2293. https://doi.org/10.1007/s10462-017-9610-2

Marani M, Songmene V, Zeinali M, Kouam J, Zedan Y (2019) Neuro-fuzzy predictive model for surface roughness and cutting force of machined Al–20 Mg2Si–2Cu metal matrix composite using additives. Neural Comput Appl. https://doi.org/10.1007/s00521-019-04314-6

Savkovic B, Kovac P, Dudic B, Rodic D, Taric M, Gregus M (2019) Application of an adaptive ‘neuro-fuzzy’ inference system in modeling cutting temperature during hard turning. Appl Sci. https://doi.org/10.3390/app9183739

Shivakoti I, Kibria G, Pradhan PM, Pradhan BB, Sharma A (2019) ANFIS based prediction and parametric analysis during turning operation of stainless steel 202. Mater Manuf Process 34(1):112–121. https://doi.org/10.1080/10426914.2018.1512134

Abbas AT, Alata M, Ragab AE, El Rayes MM, El Danaf EA (2017) Prediction model of cutting parameters for turning high strength steel grade-H: comparative study of regression model versus ANFIS. Adv Mater Sci Eng. https://doi.org/10.1155/2017/2759020

Behazin E, Misra M, Mohanty AK (2017) Sustainable biocomposites from pyrolyzed grass and toughened polypropylene: structure-property relationships. ACS Omega 2(5):2191–2199. https://doi.org/10.1021/acsomega.7b00122

T Dhaouadi (2018) Caractérisation et modélisation des propriétés mécaniques des biocomposites à fibres courtes aléatoires. Mémoire de maîtrise électronique, Montréal, École de technologie supérieure [Online] Available: http://espace.etsmtl.ca/id/eprint/2187

Savas V, Ozay C (2008) The optimization of the surface roughness in the process of tangential turn-milling using genetic algorithm. Int J Adv Manuf Technol 37(3–4):335–340. https://doi.org/10.1007/s00170-007-0984-1

Imani L, Rahmani Henzaki A, Hamzeloo R, Davoodi B (2020) Modeling and optimizing of cutting force and surface roughness in milling process of Inconel 738 using hybrid ANN and GA. Proc Inst Mech Eng Part B J Eng Manuf 234(5):920–932. https://doi.org/10.1177/0954405419889204

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Tran, D.S., Songmene, V. & Ngo, A.D. Regression and ANFIS-based models for predicting of surface roughness and thrust force during drilling of biocomposites. Neural Comput & Applic 33, 11721–11738 (2021). https://doi.org/10.1007/s00521-021-05869-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00521-021-05869-z