Abstract

Inefficient scheduling of a pipeline system may lead to severe degradation and substantial economic losses. Earlier studies mostly focussed on corrosion and statistical analysis. This study presents a novel approach for the prediction of life conditions and the classification of metal loss (ML) faults for a group of five pipeline sections of a pipeline system. An intelligent model is developed using artificial neural networks. The historical reports are grouped from the oil and gas industry located in Sudan. The results obtained by a proposed intelligent model are found to be satisfactory based on the highest coefficient of determination (R2) and the lowest mean squared error (MSE) values. The model developed with 12 number of hidden neurons accurately predicted the pipeline condition with an overall R2 value of 0.98148, 0.99359, 0.9943, 0.99336, and 0.99084 for the pipeline sections S1, S2, S3, S4, and S5, respectively. A sensitivity analysis has been carried out to understand the interrelationship between the factors affecting pipeline conditions for all sections of a pipeline system. The remaining useful life for all the sections of the pipeline system has been estimated, and a comparative analysis has been conducted in this work. The significant advantage of the present work is that the developed model can estimate the type of ML due to which the pipeline condition would mostly deteriorate. The deterioration profiles of the selected factors considered for this study have been generated, and the assessment scale has been designed. The proposed approach is more valuable in oil and gas industries to avoid unnecessary inspection costs and to plan the maintenance schedule. This study is progressively worthwhile to organize pipeline inspections and rehabilitation necessities.

Similar content being viewed by others

Explore related subjects

Discover the latest articles and news from researchers in related subjects, suggested using machine learning.References

Kennedy JL (1993) Oil and gas pipeline fundamentals. Pennwell books, Houston

Guo B, Song S, Ghalambor A, Chacko J (2005) Offshore pipelines. Elsevier, New York

Bai Y, Bai Q (2005) Subsea pipelines and risers. Elsevier, New York

Shahriar A, Sadiq R, Tesfamariam S (2012) Risk analysis for oil & gas pipelines: a sustainability assessment approach using fuzzy based bow-tie analysis. J Loss Prev Process Ind 25(3):505–523

Velazquez J, Caleyo F, Valor A, Hallen J (2009) Predictive model for pitting corrosion in buried oil and gas pipelines. Corrosion 65(5):332–342

Sinha SK, Pandey MD (2002) Probabilistic neural network for reliability assessment of oil and gas pipelines. Comput Aided Civ Infrastruct Eng 17(5):320–329

Papavinasam S, Revie RW, Friesen WI, Doiron A, Panneerselvan T (2006) Review of models to predict internal pitting corrosion of oil and gas pipelines. Corros Rev 24(3–4):173–230

Nešić S (2007) Key issues related to modelling of internal corrosion of oil and gas pipelines–A review. Corros Sci 49(12):4308–4338

Azevedo CR (2007) Failure analysis of a crude oil pipeline. Eng Fail Anal 14(6):978–994

Mahmoodian M, Li CQ (2017) Failure assessment and safe life prediction of corroded oil and gas pipelines. J Petrol Sci Eng 151:434–438

Ahammed M (1997) Prediction of remaining strength of corroded pressurised pipelines. Int J Press Vessels Pip 71(3):213–217

Nyborg R Overview of CO2 corrosion models for wells and pipelines. In: CORROSION 2002, 2002. Nace International

Nyborg R, Dugstad A (2004) Reliability and limitations of corrosion prediction tools for oil and gas pipelines. Eurocorr/2004 (Nice: CEFRACOR, 2004)

Vitse F, Alam K, Gunaltun Y, de Torreben DL, Duchet-Suchaux P (2002) Semi-empirical model for prediction of the Top-Of-the-Line corrosion risk. CORROSION/2002, paper (245)

Al-Alawi S, Al-Badi A, Ellithy K (2005) An artificial neural network model for predicting gas pipeline induced voltage caused by power lines under fault conditions. COMPEL Int J Comput Math Electr Electron Eng 24:69–80

Race JM, Dawson SJ, Stanley L, Kariyawasam S (2006) Predicting corrosion rates for onshore oil and gas pipelines. In: 2006 international pipeline conference, 2006, pp 385–396. https://doi.org/10.1115/ipc2006-10261

Papavinasam S, Doiron A, Revie RW (2010) Model to predict internal pitting corrosion of oil and gas pipelines. Corrosion 66(3):035006–035006–035011

Ren C, Qiao W, Tian X (2012) Natural gas pipeline corrosion rate prediction model based on bp neural network. In: Cao BY, Xie XJ (eds) Fuzzy engineering and operations research. Advances in intelligent and soft computing. Springer, Berlin, Heidelberg, vol 147, pp 449–455. https://doi.org/10.1007/978-3-642-28592-9_47

Zerpa LE, Aman ZM, Joshi S, Rao I, Sloan ED, Koh C, Sum A (2012) Predicting hydrate blockages in oil, gas and water-dominated systems. In: Offshore technology conference, 2012. Offshore Technology Conference,

Thodi P, Khan F, Haddara M (2013) Risk based integrity modeling of offshore process components suffering stochastic degradation. J. Qual Maint Eng 10:375–387

Senouci A, Elabbasy M, Elwakil E, Abdrabou B, Zayed T (2014) A model for predicting failure of oil pipelines. Struct Infrastruct Eng 10(3):375–387

El-Abbasy MS, Senouci A, Zayed T, Mirahadi F, Parvizsedghy L (2014) Artificial neural network models for predicting condition of offshore oil and gas pipelines. Autom Constr 45:50–65

Hillier A, Imtiaz S, Khan F, Thodi P Risk-Based Evaluation of Subsea Pipeline Leak Detection Technologies. In: International conference on offshore mechanics and arctic engineering, 2015. American Society of Mechanical Engineers, p V05BT04A051

Aljaroudi A, Khan F, Akinturk A, Haddara M, Thodi P (2015) Risk assessment of offshore crude oil pipeline failure. J Loss Prev Process Ind 37:101–109

Yang Y, Khan F, Thodi P, Abbassi R (2017) Corrosion induced failure analysis of subsea pipelines. Reliab Eng Syst Saf 159:214–222

Liu H, Khan F, Thodi P (2017) Revised burst model for pipeline integrity assessment. Eng Fail Anal 80:24–38

Wang W, Shen K, Wang B, Dong C, Khan F, Wang Q (2017) Failure probability analysis of the urban buried gas pipelines using Bayesian networks. Process Saf Environ Prot 111:678–686

Li F, Wang W, Dubljevic S, Khan F, Xu J, Yi J (2019) Analysis on accident-causing factors of urban buried gas pipeline network by combining DEMATEL, ISM and BN methods. J Loss Prev Process Ind 61:49–57

Adumene S, Khan F, Adedigba S (2020) Operational safety assessment of offshore pipeline with multiple MIC defects. Comput Chem Eng 138:106819

Shabarchin O, Tesfamariam S (2016) Internal corrosion hazard assessment of oil & gas pipelines using Bayesian belief network model. J Loss Prev Process Ind 40:479–495

Mohamed A, Hamdi MS, Tahar S (2016) A hybrid intelligent approach for metal-loss defect depth prediction in oil and gas pipelines. In: Bi Y, Kapoor S, Bhatia R (eds) Intelligent systems and applications. Studies in computational intelligence. Springer, Cham, vol 650, pp 1–18. https://doi.org/10.1007/978-3-319-33386-1_1

Tee KF, Pesinis K (2017) Reliability prediction for corroding natural gas pipelines. Tunn Undergr Space Technol 65:91–105

Tsai Y-H, Wang J, Chien W-T, Wei C-Y, Wang X, Hsieh S-H (2019) A BIM-based approach for predicting corrosion under insulation. Autom Constr 107:102923

Seghier MEAB, Keshtegar B, Tee KF, Zayed T, Abbassi R, Trung NT (2020) Prediction of maximum pitting corrosion depth in oil and gas pipelines. Eng. Fail Anal 112:104505

Salemi M, Wang H (2020) Fatigue life prediction of pipeline with equivalent initial flaw size using Bayesian inference method. J. Infrastruct Preserv Resil 1(1):1–15

Xiang W, Zhou W (2020) A nonparametric Bayesian network model for predicting corrosion depth on buried pipelines. CORROSION 76(3):235–247. https://doi.org/10.5006/3421

Basha SN, Rao PS (2018) A simulated model for assessing the line condition of onshore pipelines. In: MATEC web of conferences, 2018. EDP Sciences, p 06003

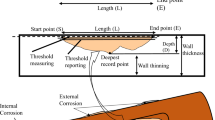

Pipeline Operators Forum (2009) Specifications and requirements for intelligent pig inspection of pipelines.

Burden F, Winkler D (2008) Bayesian regularization of neural networks. In: Livingstone DJ (ed) Artificial neural networks. Methods in Molecular Biology™, Humana Press, vol 458, pp 23–42. https://doi.org/10.1007/978-1-60327-101-1_3

Ahmad Z, Zhang J (2005) Bayesian selective combination of multiple neural networks for improving long-range predictions in nonlinear process modelling. Neural Comput Appl 14(1):78–87

Li Z, Shi K, Dey N, Ashour AS, Wang D, Balas VE, McCauley P, Shi F (2017) Rule-based back propagation neural networks for various precision rough set presented KANSEI knowledge prediction: a case study on shoe product form features extraction. Neural Comput Appl 28(3):613–630

Suliman A, Omaro BS (2018) Applying Bayesian regularization for acceleration of Levenberg–Marquardt based neural network training. IJIMAI 5(1):68–72

Thomas AJ, Petridis M, Walters SD, Gheytassi SM, Morgan RE Two hidden layers are usually better than one. In: International conference on engineering applications of neural networks, 2017. Springer, pp 279-290

Najah A, El-Shafie A, Karim OA, El-Shafie AH (2013) Application of artificial neural networks for water quality prediction. Neural Comput Appl 22(1):187–201

Fei J, Chu Y (2019) Double hidden layer output feedback neural adaptive global sliding mode control of active power filter. IEEE Trans Power Electron 35(3):3069–3084

Shaik NB, Pedapati SR, Abd Dzubir FA (2020) Remaining useful life prediction of crude oil pipeline by means of deterioration curves. Process Saf Prog 39:e12112

Yildiz B, Bilbao JI, Sproul AB (2017) A review and analysis of regression and machine learning models on commercial building electricity load forecasting. Renew Sustain Energy Rev 73:1104–1122

Desboulets LDD (2018) A review on variable selection in regression analysis. Econometrics 6(4):45

El-Abbasy MS, Senouci A, Zayed T, Mirahadi F, Parvizsedghy L (2014) Condition prediction models for oil and gas pipelines using regression analysis. J Constr Eng Manag 140(6):04014013

Senouci A, El-Abbasy MS, Zayed T (2014) Fuzzy-based model for predicting failure of oil pipelines. J Infrastruct Syst 20(4):04014018

Acknowledgements

The authors are grateful to Universiti Teknologi PETRONAS, Malaysia, for the facilities provided to conduct this research.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix: Algorithm

Appendix: Algorithm

The pseudo-code for implementing the proposed algorithm is given in Algorithm 1.

Rights and permissions

About this article

Cite this article

Shaik, N.B., Pedapati, S.R., Othman, A.R. et al. An intelligent model to predict the life condition of crude oil pipelines using artificial neural networks. Neural Comput & Applic 33, 14771–14792 (2021). https://doi.org/10.1007/s00521-021-06116-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00521-021-06116-1