Abstract

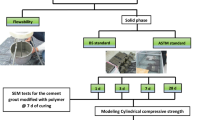

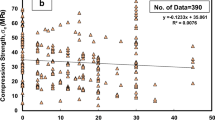

The present article discusses the impact of the different grain sizes of sand on the ultimate stress of hand-mixed cement-grouted sand modified with polycarboxylate ether-based polymer using two different test standards (American Society for Testing and Materials (ASTM) and British Standards (BS)). The fresh and hardened properties of cement-grouted sands modified with polymer up to 0.16% (% wt. of dry cement) were tested and quantified. Five types of sand with different grain sizes were used in this study. Adding polymer decreased the water/cement ratio (\(w/c\)) by 21.9 to 54.1%, and it kept the flow time of the cement-based grout in the range of 18 to 23 s. The highest compression strength was achieved at seven and 28 days for the cement-grouted sand using the coarser-graded sand than finer-graded sand at low w/c varied between 0.50 and 0.53. The highest compression strength was obtained at high w/c ranged between 0.57 and 0.60 for the cement grout mixed with the fine-grained sands compared to coarse-grained sands. Adding polymer enhances the prismatic and cylindrical compressive strength significantly by 113 to 577% and 53 to 459% depending on mix proportion and curing period. Adding polymer creates an amorphous gel that fills the porous between the particles of the cement, which causes a reduction in the voids, porosity and enhanced the dry density of the cement; subsequently, the compression strength of the cement-grouted sands increased significantly. Several approaches such as linear regression, nonlinear regression (NLR), multiple linear regression, artificial neural network (ANN), and M5P-tress were employed to predict the compression strength of cement-grouted sand with a different grain size of sand, w/c, amount of polymer, and curing age. From the scatter index and OBJ assessments and based on training and testing datasets, the compressive strength of the cement-grouted sands can be predicted well by using NLR and ANN models. The compression strength following the BS standard was 71% larger than the compression strength of the same mix using the ASTM standard.

Similar content being viewed by others

References

Ortiz RC (2015) Mechanical behavior of grouted sands

Babcock B (2013) Cement grout vs. chemical grout. Geotech Div World Tunnel, 20–21

Bungey JH, Millard SG (1996) Absorption and permeability tests. Testing of Concrete in Structures, 3rd edn. Chapman & Hall, London, UK

Mohammed MH, Pusch R, Knutsson S, Hellstr G (2014) Rheological properties of cement-based grouts determined by different techniques. Engineering

Houlsby AC (1990) Construction and design of cement grouting: a guide to grouting in rock foundations. John Wiley & Sons, Hoboken

Mahmood W, Mohammed A, Ghafor K (2019) Viscosity, yield stress and compressive strength of cement-based grout modified with polymers. Results Mater 4:100043. https://doi.org/10.1016/j.rinma.2019.100043

Mohammed A, Mahmood W, Ghafor K (2020) TGA, rheological properties with maximum shear stress and compressive strength of cement-based grout modified with polycarboxylate polymers. Constr Build Mater 235:117534

Mohammed A, Mahmood W, Ghafor K (2020) Shear stress limit, rheological properties and compressive strength of cement-based grout modified with polymers. J Build Pathol Rehabil 5(1):3. https://doi.org/10.1007/s41024-019-0069-1

Hussin MW, Lim SK (2007) Engineering properties of high volume slag cement grout in tropical climate. Malaysian J Civil Eng 19(1):42–54

Benyounes K, Benmounah A (2014) Effect of bentonite on the rheological behavior of cement grout in presence of superplasticizer. Int J Civil Architect Struct Constr Eng 8(11):1095–1098

Ghafor K, Qadir S, Mahmood W, Mohammed A (2020) Statistical variations and new correlation models to predict the mechanical behaviour of the cement mortar modified with silica fume. Geomech Geoeng, 1–13

Salih A, Rafiq S, Mahmood W, Hind AD, Noaman R, Ghafor K, Qadir W (2020) Systemic multi-scale approaches to predict the flowability at various temperature and mechanical properties of cement paste modified with nano-calcium carbonate. Constr Build Mater 262:120777

Bowen R (1981) Grouting in engineering practice. Apply Science Pub

Hatem M, Al-Ansari N, Pusch R, Knutsson S, Jonasson JE (2013) Rheological properties of low pH cement-palygorskite injection grout. J Adv Sci Eng Res 3(3):167–192

Lim SK, Tan CS, Chen KP, Lee ML, Lee WP (2013) Effect of different sand grading on strength properties of cement grout. Constr Build Mater 38:348–355

Ghafor K, Mahmood W, Qadir W, Mohammed A (2020) Effect of particle size distribution of sand on mechanical properties of cement mortar modified with Microsilica. ACI Mater J, 117(1)

Reddy BV, Gupta A (2008) Influence of sand grading on the characteristics of mortars and soil–cement block masonry. Constr Build Mater 22(8):1614–1623

Haach VG, Vasconcelos G, Lourenço PB (2011) Influence of aggregates grading and water/cement ratio in workability and hardened properties of mortars. Constr Build Mater 25(6):2980–2987

Westerholm M, Lagerblad B, Silfwerbrand J, Forssberg E (2008) Influence of fine aggregate characteristics on the rheological properties of mortars. Cement Concr Compos 30(4):274–282

Mohammed A, Rafiq S, Sihag P, Kurda R, Mahmood W (2020) Soft computing techniques: systematic multiscale models to predict the compressive strength of HVFA concrete based on mix proportions and curing times. J Build Eng, 101851

Mohammed A, Rafiq S, Mahmood W, Al-Darkazalir H, Noaman R, Qadir W, Ghafor K (2020) Artificial neural network and NLR techniques to predict the rheological properties and compression strength of cement past modified with nanoclay. Ain Shams Eng J

Mohammed A, Rafiq S, Mahmood W, Noaman R, Hind AD, Ghafor K, Qadir W (2020) Microstructure characterizations, thermal properties, yield stress, plastic viscosity and compression strength of cement paste modified with nanosilica. J Market Res 9(5):10941–10956

Mohammed A, Rafiq S, Mahmood W, Noaman R, Ghafor K, Qadir W, Kadhum Q (2020) Characterization and modeling the flow behavior and compression strength of the cement paste modified with silica nano-size at different temperature conditions. Constr Build Mater 257:119590

Mohammed A, Rafiq S, Sihag P, Mahmood W, Ghafor K, Sarwar W (2020) ANN, M5P-tree model, and nonlinear regression approaches to predict the compression strength of cement-based mortar modified by quicklime at various water/cement ratios and curing times. Arab J Geosci 13(22):1–16

Mohammed A, Rafiq S, Sihag P, Kurda R, Mahmood W, Ghafor K, Sarwar W (2020) ANN, M5P-tree and nonlinear regression approaches with statistical evaluations to predict the compressive strength of cement-based mortar modified with fly ash. J Market Res 9(6):12416–12427

Malaikah AS (2005) Effect of specimen size and shape on the compressive strength of high strength concrete. Pertanika J Sci Technol 13(1):87–96

Hamad AJ (2017) Size and shape effect of specimen on the compressive strength of HPLWFC reinforced with glass fibres. J King Saud Univ-Eng Sci 29(4):373–380

Kumari R (2015) Review paper based on the relation between the strength of concrete cubes and cylinders. Int J Eng Res Appl 5(8):52–54

Elwell DJ, Fu G (1995) Compression testing of concrete: cylinders vs. cubes (No. FHWA/NY/SR-95/119)

Sarwar W, Ghafor K, Mohammed A (2019) Modeling the rheological properties with shear stress limit and compressive strength of ordinary Portland cement modified with polymers. J Build Pathol Rehabilit 4(1):25

Mohammed A, Burhan L, Ghafor K, Sarwar W, Mahmood W (2020) Artificial neural network (ANN), M5P-tree, and regression analyses to predict the early age compression strength of concrete modified with DBC-21 and VK-98 polymers. Neural Comput Appl, 1–23

Qadir W, Ghafor K, Mohammed A (2019) Characterizing and modeling the mechanical properties of the cement mortar modified with fly ash for various water-to-cement ratios and curing times. Adv Civil Eng

Burhan L, Ghafor K, Mohammed A (2020) Evaluation and nonlinear quantification of early age strength of concrete containing PCE polymer. MS&E 737(1):012061

Sarwar W, Ghafor K, Mohammed A (2019) Regression analysis and Vipulanandan model to quantify the effect of polymers on the plastic and hardened properties with the tensile bonding strength of the cement mortar. Results Mater 1:100011

Sihag P, Jain P, Kumar M (2018) Modelling of impact of water quality on recharging rate of storm water filter system using various kernel function based regression. Model Earth Syst Environ 4(1):61–68

Mohammed A, Salih A, Raof H (2020) Vipulanandan constitutive models to predict the rheological properties and stress–strain behavior of cement grouts modified with metakaolin. J Test Eval, 48(5)

Mahmood W, Mohammed A (2019) Hydraulic Conductivity, Grain Size Distribution (GSD) and Cement Injectability Limits Predicted of Sandy Soils Using Vipulanandan Models. Geotech Geol Eng, https://doi.org/10.1007/s10706-019-01153-z

Mahmood W, Mohammed A (2020) New Vipulanandan pq model for particle size distribution and groutability limits for sandy soils. J Test Eval, 48(5)

Vipulanandan C, Mohammed A (2019) Smart cement compressive piezoresistive, stress-strain, and strength behavior with nanosilica modification. J Test Eval 47(2):1479–1501

Vipulanandan C, Mohammed A (2015) Smart cement modified with iron oxide nanoparticles to enhance the piezoresistive behavior and compressive strength for oil well applications. Smart Mater Struct 24(12):125020

Mohammed AS (2018) Vipulanandan models to predict the electrical resistivity, rheological properties and compressive stress-strain behavior of oil well cement modified with silica nanoparticles. Egypt J Pet 27(4):1265–1273

Mohammed A, Vipulanandan C (2015) Testing and modeling the short-term behavior of lime and fly ash treated sulfate contaminated CL soil. Geotech Geol Eng 33(4):1099–1114

Mohammed A, Mahmood W (2018) Vipulanandan failure models to predict the tensile strength, compressive modulus, fracture toughness and ultimate shear strength of calcium rocks. Int J Geotech Eng, 1–11

Mohammed A, Mahmood W (2018) Statistical variations and new correlation models to predict the mechanical behavior and ultimate shear strength of gypsum rock. Open Eng 8(1):213–226

Emad W, Salih A, Kurda R (2021) Stress-stain behavior, elastic modulus, and toughness of the soilcrete modified with powder polymers. Constr Build Mater 295:123621

Mawlood Y, Mohammed A, Hummadi R, Hasan A, Ibrahim H, Modeling and statistical evaluations of unconfined compressive strength and compression index of the clay soils at various ranges of liquid limit, J Test Eval, https://doi.org/10.1520/JTE20200505

Quinlan JR (1992) Learning with continuous classes. In 5th Australian joint conference on artificial intelligence (Vol. 92, pp. 343–348)

Faraj RH, Mohammed AA, Mohammed A, Omer KM, Ahmed HU (2021) Systematic multiscale models to predict the compressive strength of self-compacting concretes modified with nanosilica at different curing ages. Eng Comput, 1–24

Zeng F, Amar MN, Mohammed AS, Motahari MR, Hasanipanah M (2021) Improving the performance of LSSVM model in predicting the safety factor for circular failure slope through optimization algorithms. Eng Comput, 1–12

Funding

No fund was received.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Data availability statement

No data, models, or code were generated or used during the study.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mahmood, W., Mohammed, A. Performance of ANN and M5P-tree to forecast the compressive strength of hand-mix cement-grouted sands modified with polymer using ASTM and BS standards and evaluate the outcomes using SI with OBJ assessments. Neural Comput & Applic 34, 15031–15051 (2022). https://doi.org/10.1007/s00521-022-07349-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00521-022-07349-4