Abstract

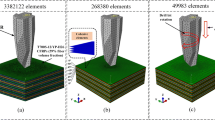

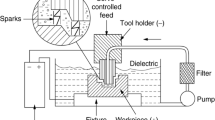

The Equal Channel Angular Pressing-Conform (ECAP-C) process is one of the Severe Plastic Deformation (SPD) methods used to create the ultrafine-grained structure. The current study investigates an optimized artificial neural network for modeling the ECAP-C process based on experimental tests and finite element methods. The ECAP-C process of AA 7075 was performed for validation of the finite element model. After validating, the design of experiments was carried out using the response surface method. The process parameters include the rotary wheel radius, the rod contact angle, the die channel angle, outer corner angle of die, the friction coefficient (between rod and roller, and between rod and die), and the aspect ratio of the die channel. Moreover, the responses are the required torque, yield strength, output rod curvature, and strain non-uniformity at the rod cross section. For modeling with the neural network, a Multi-Layer Perceptron (MLP) network is considered, while its structure is optimized using two metaheuristic methods, i.e., Particle Swarm Optimization (PSO) and Whale Optimization Algorithm (WOA). It was found that the MLP network with two hidden layers can efficiently predict the process outputs, with 40 and 7 neurons in its first and second hidden layers, respectively. Furthermore, the comparison of experimental and numerical results has an acceptable agreement.

Similar content being viewed by others

Explore related subjects

Discover the latest articles and news from researchers in related subjects, suggested using machine learning.References

Wei W, Zhang W, Wei KX et al (2009) Finite element analysis of deformation behavior in continuous ECAP process. Mater Sci Eng A 516:111–118. https://doi.org/10.1016/j.msea.2009.03.001

Horita Z, Nemoto M, Langdon TG (1997) An investigation of microstructural evolution during equal-channel angular pressing. Acta Mater 45:4733–4741

Raab GJ, Valiev RZ, Lowe TC, Zhu YT (2004) Continuous processing of ultrafine grained Al by ECAP-Conform. Mater Sci Eng A 382:30–34. https://doi.org/10.1016/j.msea.2004.04.021

Prell M, Xu C, Langdon TG (2008) The evolution of homogeneity on longitudinal sections during processing by ECAP. Mater Sci Eng A 480:449–455. https://doi.org/10.1016/j.msea.2007.08.011

Etherington C (1974) Conform—A new concept for the continuous extrusion forming of metals. J Eng Ind 96:893–900. https://doi.org/10.1115/1.3438458

Xu C, Schroeder S, Berbon PB, Langdon TG (2010) Principles of ECAP-Conform as a continuous process for achieving grain refinement: application to an aluminum alloy. Acta Mater 58:1379–1386. https://doi.org/10.1016/j.actamat.2009.10.044

Murashkin M, Medvedev A, Kazykhanov V et al (2015) Enhanced mechanical properties and electrical conductivity in ultrafine-grained Al 6101 alloy processed via ECAP-conform. Metals (Basel) 5:2148–2164

Derakhshan JF, Parsa MH, Jafarian HR (2019) Microstructure and mechanical properties variations of pure aluminum subjected to one pass of ECAP-conform process. Mater Sci Eng A 747:120–129. https://doi.org/10.1016/j.msea.2019.01.058

Shahab AR, Akbari Mousavi SAA, Ranjbar Bahadori S, Ebrahimi SM (2012) The comparison between continuous confined strip shearing (C2S2) and ECAP conform in regard to equivalent plastic strain distribution for Al 1100. Int J Mod Phys Conf Ser 05:400–409. https://doi.org/10.1142/S2010194512002280

Gholami J, Pourbashiri M, Sedighi M (2015) Effect of channel angle and friction in modified ECAP-CONFORM process of Al-6061: a numerical study. Iran J Mater Sci Eng 12:71–76. https://doi.org/10.22068/ijmse.12.4.71

Ghaforian Nosrati H, Khalili K, Gerdooei M (2020) Theoretical and numerical investigation of required torque in ECAP-Conform process. Metall Mater Trans B 51:519–528. https://doi.org/10.1007/s11663-020-01797-w

Nosrati HG, Khalili K, Gerdooei M (2021) Theoretical and experimental evaluation of no-slip feeding condition in ECAP-Conform of a square-section metallic rod. Int J Adv Manuf Technol 112:375–385. https://doi.org/10.1007/s00170-020-06395-3

Esmailzadeh M, Aghaie-Khafri M (2012) Finite element and artificial neural network analysis of ECAP. Comput Mater Sci 63:127–133

Irfan OM, Omar HM (2019) Influence of grain refinement by ECAP on mechanical and erosion corrosion properties of AISI 4130 steel: experimental and prediction approach. Metall Mater Trans A 50:4232–4244

Salcedo D, Luis CJ, Puertas I et al (2014) FEM modelling and experimental analysis of an AA5083 turbine blade from ECAP processed material. Mater Manuf Process 29:434–441

Salcedo D, Luis CJ, Leon J et al (2015) Simulation and analysis of isothermal forging of AA6063 obtained from material processed by equal channel angular pressing severe plastic deformation. Proc Inst Mech Eng Part B J Eng Manuf 229:727–743

Mahmoodi M, Naderi A (2016) Applicability of artificial neural network and nonlinear regression to predict mechanical properties of equal channel angular rolled Al5083 sheets. Lat Am J Solids Struct 13:1515–1525

Djavanroodi F, Omranpour B, Sedighi M (2013) Artificial neural network modeling of ECAP process. Mater Manuf Process 28:276–281

Samaniego E, Anitescu C, Goswami S et al (2020) An energy approach to the solution of partial differential equations in computational mechanics via machine learning: concepts, implementation and applications. Comput Methods Appl Mech Eng 362:112790. https://doi.org/10.1016/j.cma.2019.112790

Zhuang X, Guo H, Alajlan N et al (2021) Deep autoencoder based energy method for the bending, vibration, and buckling analysis of Kirchhoff plates with transfer learning. Eur J Mech A/Solids 87:104225. https://doi.org/10.1016/j.euromechsol.2021.104225

Nguyen-Thanh VM, Anitescu C, Alajlan N et al (2021) Parametric deep energy approach for elasticity accounting for strain gradient effects. Comput Methods Appl Mech Eng 386:114096. https://doi.org/10.1016/j.cma.2021.114096

Rao SS (2019) Engineering optimization: theory and practice. Wiley, Hoboken

Rahmati A, Varedi-Koulaei SM, Ahmadi MH, Ahmadi H (2022) Dynamic synthesis of the alpha-type stirling engine based on reducing the output velocity fluctuations using metaheuristic algorithms. Energy 238:121686. https://doi.org/10.1016/j.energy.2021.121686

Poli R, Kennedy J, Blackwell T (2007) Particle swarm optimization. Swarm Intell 1:33–57. https://doi.org/10.1007/s11721-007-0002-0

Mirjalili S, Lewis A (2016) The whale optimization algorithm. Adv Eng Softw 95:51–67. https://doi.org/10.1016/j.advengsoft.2016.01.008

Foroutan K, Varedi-Koulaei SM, Duc ND, Ahmadi H (2021) Non-linear static and dynamic buckling analysis of laminated composite cylindrical shell embedded in non-linear elastic foundation using the swarm-based metaheuristic algorithms. Eur J Mech 91:104420

Hosford WF, Caddell RM (2007) Metal forming: mechanics and metallurgy. Cambridge University Press, Cambridge

Funding

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper. Also, all authors read and approved the final manuscript.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Moradi, S., Gerdooei, M., Varedi-Koulaei, S.M. et al. MLP neural network with an optimal architecture for modeling the ECAP-C process. Neural Comput & Applic 35, 2701–2715 (2023). https://doi.org/10.1007/s00521-022-07685-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00521-022-07685-5