Abstract

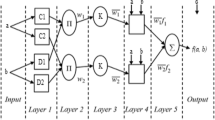

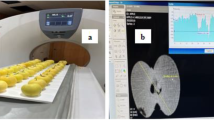

In this research, the main goal is to develop and apply a robust adaptive fuzzy inference system (ANFIS) and Analysis of Variance (ANOVA) models to predict the mass transfer during osmotically treated zucchini samples as a heat-sensitive product. Maltose, fructose, lactose, and fructo-oligosaccharide (FoS), as osmotic agents at various concentrations and at constant temperature, were applied. In this study, the investigated concentrations were 30%, 40%, and 50% and the temperature was at 26 °C. Three performance outputs were considered: Dimensionless Moisture Content (DMC), Water Loss (WL), and Solid Gain (SG). Using the dataset obtained from the experiments, both ANFIS and ANOVA models were proposed to describe osmotic dehydration behavior. The inputs to the models are the time (min), the concentrations (%) and the osmotic agents. During the training and testing phases, the ANFIS showed significant modeling performances relative to the ANOVA in terms of the coefficient-of-determination (R2) and the RMSE values. In particular, for the whole dataset, the RMSE values are improved using ANFIS compared to the ANOVA where they are decreased by 99.03%, 93.5% and 79.08%, for the DMC, SG and WL, respectively. On the other hand, the coefficient-of-determination showed significant increases for the ANFIS models over the ANOVA models for both training and testing phases. The comparison between the two modeling techniques revealed that the ANFIS is found more suitable for predicting all three performance outputs during the Osmotic Dehydration (OD) process of the zucchini food product. The results showed that the maltose, as an osmotic agent, with a concentration of 30% is the most suitable solution among the four osmotic agents that produced the best performance for the three performance outputs. In sum, the obtained results demonstrated the superiority of ANFIS modeling of the DMC, SG, and WL in comparison with ANOVA. Accordingly, the prediction from the ANFIS model has an excellent agreement with the experimental dataset. This confirms the accuracy of the ANFIS model.

Similar content being viewed by others

Explore related subjects

Discover the latest articles and news from researchers in related subjects, suggested using machine learning.Abbreviations

- M o :

-

Initial mass of the material (g)

- M d :

-

Initial bone-dry mass of the sample material (g)

- M t :

-

Mass of the sample at t time (g)

- M td :

-

Bone-dry mass of the sample at time t (g) during the osmotic dehydration process (g)

- m ds :

-

Mass of dry solid (g)

- M e :

-

Equilibrium moisture content (dry basis) (kg/kg)

- M o :

-

Initial moisture content (dry basis) (kg/kg)

- Mt :

-

Moisture content at time t (dry basis) (kg/kg)

- D eff :

-

Effective moisture diffusivity (m2/s)

- K:

-

Thermal diffusivity (m2/s)

- r :

-

Radius (m)

- t :

-

Time (s)

- dt :

-

Change in time

- MR:

-

Moisture ratio

- R 2 :

-

Coefficient of determination

- T :

-

Temperature (oC)

- WL:

-

Water loss

- COG:

-

Center of gravity

- FL:

-

Fuzzy logic

- MF:

-

Membership function

- MSE:

-

Mean square error

- RMSE:

-

Root-mean-square error

- SC:

-

Subtractive clustering

- TSK:

-

Takagi–Sugeno–Kang

References

Nimmanpipug N, Therdthai N, Dhamvithee P (2013) Characterisation of osmotically dehydrated papaya with further hot air drying and microwave vacuum drying. Int J Food Sci Technol 48:1193–1200

Gomes Alves D, Lucena Barbosa JJ, ColatoAntonio G, Xidieh Murr FE (2005) Osmotic dehydration of acerola fruit (Malpighia punicifolia L). J food Eng 68:99–103

Mujica-Paz H, Valdez-Fragoso A, López-Malo A, Palou E, Welti-Chanes J (2003) Impregnation and osmotic dehydration of some fruits: effect of the vacuum pressure and syrup concentration. J Food Eng 57:305–314

Sacchetti G, Gianotti A, Dalla Rosa M (2001) Sucrose–salt combined effects on mass transfer kinetics and product acceptability. study on apple osmotic treatments. J Food Eng 49:163–173

Azoubel PM, Murr FEX (2004) Mass transfer kinetics of osmotic dehydration of cherry tomato. J Food Eng 61:291–295

Ahmed I, Qazi IM, Jamal S (2016) Developments in osmotic dehydration technique for the preservation of fruits and vegetables. Innov Food Sci Emerg Technol 34:29–43

Bakalis S, Karathanos VT (2005) Study of rehydration of osmotically pretreated dried fruit samples. Drying Technol 23:533–549

Uddin MB, Ainsworth P, İbanoğlu Ş (2004) Evaluation of mass exchange during osmotic dehydration of carrots using response surface methodology. J Food Eng 65:473–477

Md Atiqure Rahman S, Enamul Hoque M, Rahman S, Mahbubur Rahman M (2017) A novel vortex tube-assisted atmospheric freeze-drying system: effect of osmotic pretreatment on biological products. J Food Process Eng 40:e12449

Salazar-López EI, Jiménez M, Salazar R, Azuara E (2015) Incorporation of microcapsules in pineapple intercellular tissue using osmotic dehydration and microencapsulation method. Food Bioprocess Technol 8:1699–1706

Corrêa JL, Pereira LM, Vieira GS, Hubinger MD (2010) Mass transfer kinetics of pulsed vacuum osmotic dehydration of guavas. J Food Eng 96:498–504

Falade KO, Igbeka JC, Ayanwuyi FA (2007) Kinetics of mass transfer, and colour changes during osmotic dehydration of watermelon. J Food Eng 80:979–985

Hu Q-G, Zhang M, Mujumdar AS, Xiao G-N, Jin-cai S (2006) Drying of edamames by hot air and vacuum microwave combination. J Food Eng 77:977–982

Mandala I, Anagnostaras E, Oikonomou C (2005) Influence of osmotic dehydration conditions on apple air-drying kinetics and their quality characteristics. J Food Eng 69:307–316

Lewicki PP, Porzecka-Pawlak R (2005) Effect of osmotic dewatering on apple tissue structure. J Food Eng 66:43–50

Kanagaratnam S, Hoque ME, Sahri MM, Spowage A (2013) Investigating the effect of deforming temperature on the oil-binding capacity of palm oil based shortening. J Food Eng 118:90–99

Deng Y, Zhao Y (2008) Effect of pulsed vacuum and ultrasound osmopretreatments on glass transition temperature, texture, microstructure and calcium penetration of dried apples (Fuji). LWT-Food Sci Technol 41:1575–1585

Kowalski S, Mierzwa D (2013) Influence of osmotic pretreatment on kinetics of convective drying and quality of apples. Drying Technol 31:1849–1855

Kek S, Chin N, Yusof Y (2013) Direct and indirect power ultrasound assisted pre-osmotic treatments in convective drying of guava slices. Food Bioprod Process 91:495–506

Garcia-Noguera J, Oliveira FI, Gallão MI, Weller CL, Rodrigues S, Fernandes FA (2010) Ultrasound-assisted osmotic dehydration of strawberries: effect of pretreatment time and ultrasonic frequency. Drying Technol 28:294–303

Segui L, Fito P, Albors A, Fito P (2006) Mass transfer phenomena during the osmotic dehydration of apple isolated protoplasts (Malus domestica var. Fuji). J Food Eng 77:179–187

Nassef AM, Fathy A, Sayed ET, Abdelkareem MA, Rezk H, Tanveer WH, Olabi A (2019) Maximizing SOFC performance through optimal parameters identification by modern optimization algorithms. Renew Energy 138:458–464

Özdemir MB, Aktaş M, Şevik S, Khanlari A (2017) Modeling of a convective-infrared kiwifruit drying process. Int J Hydrogen Energy 42:18005–18013

Nassef AM, Rahman SMA, Rezk H, Said Z (2020) ANFIS-based modelling and optimal operating parameter determination to enhance cocoa beans drying-rate. IEEE Access 8:45964–45973

Boukezzi L, Bessissa L, Boubakeur A, Mahi D (2017) Neural networks and fuzzy logic approaches to predict mechanical properties of XLPE insulation cables under thermal aging. Neural Comput Appl 28:3557–3570

Entchev E, Yang L (2007) Application of adaptive neuro-fuzzy inference system techniques and artificial neural networks to predict solid oxide fuel cell performance in residential microgeneration installation. J Power Sources 170:122–129

Tarasov V, Tan H, Jarfors AE, Seifeddine S (2020) Fuzzy logic-based modelling of yield strength of as-cast A356 alloy. Neural Comput Appl 32:5833–5844

Nassef AM, Sayed ET, Rezk H, Abdelkareem MA, Rodriguez C, Olabi A (2019) Fuzzy-modeling with particle swarm optimization for enhancing the production of biodiesel from Microalga. Energy Sour Part A 41:2094–2103

Jansen J, Hoefsloot H, van der Greef J, Timmerman ME, Smilde AK (2005) Multilevel component analysis of time-resolved metabolic fingerprint data. Anal Chim Acta 530:173–183

Jansen JJ, Hoefsloot HC, van der Greef J, Timmerman ME, Westerhuis JA, Smilde AK (2005) ASCA: analysis of multivariate data obtained from an experimental design. J Chemom 19:469–481

Smilde AK, Jansen JJ, Hoefsloot HC, Lamers R-JA, Van Der Greef J, Timmerman ME (2005) ANOVA-simultaneous component analysis (ASCA): a new tool for analyzing designed metabolomics data. Bioinformatics 21:3043–3048

Khakimov B, Gürdeniz G, Engelsen SB (2015) Trends in the application of chemometrics to foodomics studies. Acta Aliment 44:4–31

Kuitche A, Edoun M, Takamte G (2007) Influence of pre-treatment on drying on the drying kinetic of a local Okro (Hibiscus ersculentus) variety. World J Dairy Food Sci 2:83–88

Yousef BA, Rezk H, Abdelkareem MA, Olabi AG, Nassef AM (2020) Fuzzy modeling and particle swarm optimization for determining the optimal operating parameters to enhance the bio-methanol production from sugar cane bagasse. Int J Energy Res 44:8964–8973

Rahman SA, Nassef AM, Rezk H, Assad MEH, Hoque ME (2021) Experimental investigations and modeling of vacuum oven process using several semi-empirical models and a fuzzy model of cocoa beans. Heat Mass Transf 57:175–188

Dritsa V, Rigas F, Doulia D, Avramides E, Hatzianestis I (2009) Optimization of culture conditions for the biodegradation of lindane by the polypore fungus Ganoderma australe. Water Air Soil Pollut 204:19–27

Acknowledgements

Our heartiest appreciation to Eng. Salah Yousry Elsayed Issa Elsayed for the helpful assistance on preparing this research. We would also like to thank Mrs. Fatima Al-Suwaidi, Mrs. Mayyas Al-Salman, and Mrs. Suzan Al-Sanea for their assistance.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Rahman, S.M.A., Rezk, H., Shaikh, B. et al. Prediction of mass transfer during osmotically treated zucchini fruit product using advanced fuzzy inference system. Neural Comput & Applic 35, 3125–3141 (2023). https://doi.org/10.1007/s00521-022-07870-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00521-022-07870-6