Abstract

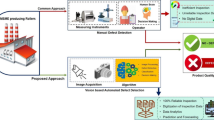

In this paper, a deep learning-based machine vision approach is proposed to automatically detect and classify defective tiles in the production assembly line of a tile manufacturing industry. The deep learning model used in this methodology is trained with 30,000 real-time images of cement/ceramic tiles, and the features of the image samples are extracted using the convolutional layers in the model. The defective tiles are identified and classified using an optimized activation function that acts as the decision-making layer or output layer of the deep learning model. The performance of this deep learning technique is evaluated using various metrics like accuracy, precision, recall and f1-score which is further compared with state-of-the-art activation functions like Relu, sigmoid, tanh and softmax. To further enhance the performance metrics, the feature extraction is done using various pre-trained models like VGG-16, Resnet50 and InceptionV3 and was further evaluated using metrics like K (Kappa statistic), OA (overall accuracy) and AA (average accuracy). The obtained experimental results with an accuracy of 99.96% under a favorable learning rate prove the robustness and efficiency of the proposed methodology to enhance industrial quality control in any tile manufacturing industry.

Similar content being viewed by others

Data availability

The data associated with this work will be made available on reasonable request.

References

Fernando G, Maria S, Anna M, Marco C (2020) Sustainability transition in industry 4.0 and smart manufacturing with the triple-layered business model canvas. Sustainability. 12(6):1–19. https://doi.org/10.3390/su12062364

Qiwo L, Xiaoxin F, Chunhua Y, Yichuang S (2020) Automated visual defect detection for flat steel surface: a survey. IEEE Trans Instrum Meas 69(3):626–644. https://doi.org/10.1109/TIM.2019.2963555

Jing Y, Shaobo L, Zheng W, Hao D, Jun W, Shihao T (2020) Using deep learning to detect defects in manufacturing: a comprehensive survey and current challenges. Materials 13(24):1–23. https://doi.org/10.3390/ma13245755

Mallari S, Veeresh U, Chakrapani T, Sudhakar K (2018) Detection of defects and classification using image processing both for plain and textured ceramic tile images. Int J Adv Technol Innov Res (IJATIR) 10(4):0465–0470

Luofeng X, Xiao X, Huining X, Ling W, Lijun L, Guofu Y (2021) FFCNN: a deep neural network for surface defect detection of magnetic tile. IEEE Trans Industr Electron 68(4):3506–3516. https://doi.org/10.1109/TIE.2020.2982115

Huang Y, Qiu C, Yuan K (2020) Surface defect saliency of magnetic tile. Vis Comput 36:85–96. https://doi.org/10.1007/s00371-018-1588-5

Elias M, Euripides P, Michalis Z (2003) A survey on industrial vision systems, applications and tools. Image Vis Comput 21(2):171–188. https://doi.org/10.1016/S0262-8856(02)00152-X

Baig M, Sumesh N, Siva P (2016) Identification and rejection of defective ceramic tiles using image processing. Int J Modern Trends Sci Technol 2(4):57–60

Marco R, Bastian W, Bodo R (2020) Same same but DifferNet: semi-supervised defect detection with normalizing flows. In: Proceedings of the IEEE/CVF winter conference on applications of computer vision, 1907–1916

Li D, Niu Z, Peng D (2019) Magnetic tile surface defect detection based on texture feature clustering. J Shanghai Jiaotong Univ Sci. 24:663–670. https://doi.org/10.1007/s12204-019-2101-7

Tamás C, Gastone C, Mario M, Marcello C, Stefano R, Calogero M, Paolo D (2020) Visual-based defect detection and classification approaches for industrial applications—a survey. Sensors 20(5):1–25. https://doi.org/10.3390/s20051459

Wenzhe L, Jiehua ZS, Zhongzhu Z, Li L (2021) Binary neural network for automated visual surface defect detection. Sensors 21(20):1–16. https://doi.org/10.3390/s21206868

Zhao Z (2021) Review of non-destructive testing methods for defect detection of ceramics. Ceram Int 47(4):4389–4397. https://doi.org/10.1016/j.ceramint.2020.10.065

Liang W, Sun Y (2022) ELCNN: a deep neural network for small object defect detection of magnetic tile. IEEE Trans Instrum Meas 71:1–10. https://doi.org/10.1109/TIM.2022.3193175

Andrzej S (2020) Automated control of surface defects on ceramic tiles using 3D image analysis. Materials 13(5):1–13. https://doi.org/10.3390/ma13051250

Bin X, Wenbo Y, Yurong W (2018) Design of machine vision defect detecting system based on halcon. Adv Eng Res 154:351–354. https://doi.org/10.2991/meees-18.2018.61

Qi S, Yang J, Zhong Z (2020) A review on industrial surface defect detection based on deep learning technology. In: 2020 the 3rd international conference on machine learning and machine intelligence, pp 24–30

Riza A, Ade W (2019) Rafie: defect detection of ceramic tiles using median filtering, morphological techniques, gray level co-occurrence matrix and k-nearest neighbor method. Sci Res J 7(4):41–45

Huailiang Z, Ling P, Sheng Y, Wei Q (2021) Detection of surface defects in ceramic tiles with complex texture. IEEE Access 9:92788–92797. https://doi.org/10.1109/ACCESS.2021.3093090

Lu Q, Lin J, Luo L, Zhang Y, Zhu W (2022) A supervised approach for automated surface defect detection in ceramic tile quality control. Adv Eng Inform 53:101692. https://doi.org/10.1016/j.aei.2022.101692

Quentin B, Nicolas V, Matthew T, Philippe B (2020) Detecting defects in materials using deep convolutional neural networks. In: Campilho A, Karray F, Wang Z (eds) Image analysis and recognition. Springer International Publishing, pp 293–306

Cui L, Jiang X, Xu M, Li W, Lv P, Zhou B (2021) SDDNet: a fast and accurate network for surface defect detection. IEEE Trans Instrum Meas 70:1–13. https://doi.org/10.1109/TIM.2021.3056744

Changsheng L, Yanjiang H, Hai L, Xianmin Z (2020) A weak supervision machine vision detection method based on artificial defect simulation. Knowl Based Syst. https://doi.org/10.1016/j.knosys.2020.106466

Ohemu MF, Tijani SA, Ohunene ZZ, Ezefosie N (2021) Development of automated ceramic tiles surface defect detection and classification system. Development 8

Marcelino P (2018) Transfer learning from pre-trained models. Towards Data Science

Jogin M, Mohana M, Madhulika G, Divya R, Meghana K, Apoorva S (2018) Feature extraction using convolution neural networks (CNN) and deep learning. In 23rd IEEE international conference on recent trends in electronics, information and communication technology (RTEICT), pp 2319–2323

Yu Han L (2018) Feature extraction and image recognition with convolutional neural networks. IOP Conf Series J Phys Conf Series 1087

Brownlee J (2019) Deep learning for computer vision: image classification, object detection, and face recognition in python. Machine learning mastery

Rolan H (2021) Extract features, visualize filters and feature maps in VGG16 and VGG19 CNN models. Towards Data Science

Krishna S, Kalluri H (2019) Deep learning and transfer learning approaches for image classification. Int J Recent Technol Eng (IJRTE) 7(5S4):427–432

Hussain M, Bird J, Faria R (2018) A study on cnn transfer learning for image classification.UK Workshop on computational Intelligence. Springer. pp 191–202

Huang Y, Qiu C, Wang X, Wang S, Yuan K (2020) A compact convolutional neural network for surface defect inspection. Sensors. https://doi.org/10.3390/s20071974

Sharma S, Sharma S, Athaiya A (2017) Activation functions in neural networks. Towards data science

Daqi G, Yan J (2005) Classification methodologies of multilayer perceptrons with sigmoid activation functions. Pattern Recogn 38(10):1469–1482. https://doi.org/10.1016/j.patcog.2005.03.024

Ruder S (2016) An overview of gradient descent optimization algorithms. https://arxiv.org/abs/1609.04747

Bera S, Shrivastava V (2020) Analysis of various optimizers on deep convolutional neural network model in the application of hyperspectral remote sensing image classification. Int J Remote Sens 41(7):2664–2683. https://doi.org/10.1080/01431161.2019.1694725

Dogo EM, Afolabi O, Nwulu N, Twala B, Aigbavboa C (2018) A comparative analysis of gradient descent-based optimization algorithms on convolutional neural networks. In: 2018 International conference on computational techniques, electronics and mechanical systems (CTEMS), pp 92–99

Kandel I, Castelli M, Popovič A (2020) Comparative study of first order optimizers for image classification using convolutional neural networks on histopathology images. J Imaging. https://doi.org/10.3390/jimaging6090092

Zhang Z (2018) Improved adam optimizer for deep neural networks.IEEE/ACM 26th International Symposium on Quality of Service-IWQoS

Bock S, Weiß M (2019) A proof of local convergence for the Adam optimizer. In International Joint Conference on Neural Networks-IJCNN

Li L, Xu W, Yu H (2020) Character-level neural network model based on Nadam optimization and its application in clinical concept extraction. Neurocomputing. https://doi.org/10.1016/j.neucom.2020.07.027

Shung K (2018) Accuracy, precision, recall or F1. Towards data science

Joshi R (2018) Accuracy, precision, recall and f1 score: Interpretation of performance measures

Brownlee J (2020) How to Calculate Precision, Recall, and F-Measure for Imbalanced Classification-Machine Learning Mastery

Sokolova M, Japkowicz N, Szpakowicz S (2006) Beyond accuracy, F-score and ROC: a family of discriminant measures for performance evaluation. In Australasian joint conference on artificial intelligence. Springer, Heidelberg

Acknowledgements

We express our gratitude to Mr. S. Sarone Thomas, Director of R.M.S.T Tiles Factory, Tamilnadu, India, who supported the research by allowing us to study, acquire data and analyze the quality control procedures and manufacturing process.

Funding

There are no funding associated with this research publication.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kovilpillai, J.J.A., Jayanthy, S. An optimized deep learning approach to detect and classify defective tiles in production line for efficient industrial quality control. Neural Comput & Applic 35, 11089–11108 (2023). https://doi.org/10.1007/s00521-023-08283-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00521-023-08283-9