Abstract

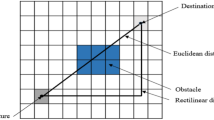

One of the problems encountered in the design and implementation of a flexible transfer line (FTL) is the layout design of the FTL. The layout design of the FTL has an important impact on material handling. In this paper, we develop a LAyout Design system (LAD). LAD can find FTL layout design including the buffer size between each pair of FTL machine tools. LAD divides the goal plant into cells and uses GA to find the efficient FTL layout design. In order to carry out GA, we propose a new encoding method to express GA individual. The new encoding method is called a One by One Encoding Method (OOEM). OOEM generates the elements of the individual one by one with the sequence of relative direction of the FTL components. The sequence of individual elements indicates the sequence of machine tools and conveyer buffer spaces of FTL. The developed LAD based on the proposed OOEM is not limited to a single static environment plant, but is highly flexible within the plant structure. An application example was developed, and after a number of generations based on LAD, an efficient FTL layout design was able to be found.

Similar content being viewed by others

References

Tompkins J, White J, Bozer Y, Frazella E, Tanchoco J (1996) Facilities Planning, 2nd edn, Wiley, New York

Suresh G, Sahu S (1993) Multiobjective facility layout using simulated annealing. Intl J Production Economics 32:39–54

Conway D, Venkataramanan M (1994) Genetic search and dynamic facility layout problem. Computers Operations Res 21(8):955–960

Raoot AD, Rakshit A (1994) Fuzzy’ heuristic for the quadratic assignment formulation to the facility layout problem. Intl J Production Res 32(3):563–581

Heragu SS, Alfa AS (1992) Experimental analysis of simulated annealing based algorithm for the layout problem. Eur J Operational Res 57(2):190–202

Solimanpur M, Vrat P, Shankar R (2005) An ant algorithm for the single row layout problem in flexible manufacturing system. Computers Operations Res 32:583–598

Kumar KR, Hadjinicola GC (1995) A heuristic procedure for the single row facilities layout problem. Eur J Operational Res 87: 65–73

Yang T, Peters B, Tu M (2005) Layout design for flexible manufacturing systems considering single loop directional flow patterns. Eur J Operational Res 146:440–455

Author information

Authors and Affiliations

Corresponding author

Additional information

This work was presented in part at the 13th International Symposium on Artificial Life and Robotics, Oita, Japan, January 31–February 2, 2008

About this article

Cite this article

Yamamoto, H., Abu Qudeiri, J., Yamada, T. et al. Production layout design system by GA with one by one encoding method. Artif Life Robotics 13, 234–237 (2008). https://doi.org/10.1007/s10015-008-0569-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10015-008-0569-6