Abstract

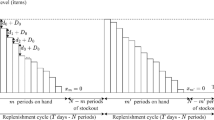

In general, production quantities and goods delivered are changed randomly, and then the total stock is also changed randomly. This article deals with the production and inventory control of an automobile production parts line using a dynamic Bayesian network. A Bayesian network indicates the quantitative relations between individual variables by conditional probability. The probabilistic distribution of the total stock is calculated through the propagation of the probability on the network. Moreover, an adjusting rule for the production quantities to maintain the probability of the lower and upper bound values of the total stock at certain values is shown.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.References

Seferlis P, Giannelos NF (2004) A two-layered optimization-based control strategy for multi-echelon supply chain networks. Comput Chem Eng 28:799–809

Suguro T, Kuroda M (2004) Safety stock and reorder point for reordering point system with variable lead times. J Jpn Indust Manag Assoc 55:89–94

Siver EA, et al (1998) Inventory management and production planning and scheduling. Wiley, New York

Biedermann A, Taron F (2006) Bayesian networks and probabilistic reasoning about scientific evidence when there is a lack of data. Forensic Sci Int 157:163–167

Neapolitan RE (2003) Learning Bayesian networks. Prentice Hall, Englewood Cliffs

Kazuo T (1995) Model dynamics and function of a complex system. Syst Control Inform 39:29–34

Kao H-Y, Huang S-H, Li H-L (2005) Supply chain diagnostics with dynamic Bayesian networks. Comput Indust Eng 49:339–347

Author information

Authors and Affiliations

Corresponding author

Additional information

This work was presented in part at the 14th International Symposium on Artificial Life and Robotics, Oita, Japan, February 5–7, 2009

About this article

Cite this article

Park, YH., Shin, JS., Woo, KY. et al. Production adjusting method based on the predicted distribution of production and inventory using a dynamic Bayesian network. Artif Life Robotics 14, 138–143 (2009). https://doi.org/10.1007/s10015-009-0727-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10015-009-0727-5