Abstract

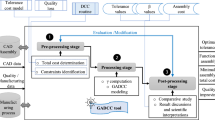

Recently, process capabilities for machining and measurement in manufacturing industries have been increasing in response to customer demand for improved product performance, and these requirements will continue to grow as technology advances. To satisfy this consumer demand, we have studied a tolerance method using statistical tolerance indices to specify the limitation of process capability indices. In this paper, we propose a method of allocating statistical tolerance indices using genetic algorithms. The proposed method is applied to a product model comprising five parts, assembled in linear combination, to confirm its effectiveness.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.References

V Srinivasan., “Dimensioning and tolerancing handbook,” McGraw-Hill, Chapter 8, 1999.

Srinivasan V, O’connor MA, Scholz FW (1997) Techniques for Composing a Class of Statistical Tolerance Zones. Advanced Tolerancing Techniques, Wiley, Chapter 6:201–219

A Otsuka (2012) “Advanced tolerancing based on product performance by using statistical tolerance index Cpk and Cc,” Emerging Technology in Precision Engineering XIV, pp 781–786

Shan A, Roth RN (2003) Genetic algorithms in statistical tolerancing. Mathematical and computer modelling 38:1427–1436

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Otsuka, A., Nagata, F. Optimal allocation of statistical tolerance indices by genetic algorithms. Artif Life Robotics 19, 227–232 (2014). https://doi.org/10.1007/s10015-014-0157-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10015-014-0157-x