Abstract

The authors are studying to control the locomotion of the microrobot system using hardware neural networks (HNN). In previous research, a waveform generator was used to drive the electrostatic actuators of the microrobot. Once the driving circuit is constructed using HNN, the controlling circuit and the driving circuit can be integrated into a single chip. In this paper, the authors will propose the driving circuit using HNN. The HNN consists of two self-oscillating cell body models, six separately-excited cell body models, four excitatory-synaptic models, and six inhibitory-synaptic models. The single self-oscillating cell body model outputs the electrical oscillated square waveform as 3 MHz of frequency. The proposed HNN generates a long delay without using large capacitors. As a result, the proposed HNN can generate the driving waveform of electrostatic actuators with variable frequency. The frequency of the driving waveform could vary from 50 to 100 Hz. Also, the proposed HNN connected to the Central Pattern Generator (CPG) model. The CPG model with proposed HNN outputs the driving waveform of the electrostatic actuator which can perform the tripod gait pattern of the microrobot.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.References

Saito K, Takato M, Sekine Y (2012) Biomimetics micro robot with active hardware neural networks locomotion control and insect-like switching behaviour. In: Proceedings of the 2009 international joint conference on neural networks, Atlanta, Georgia, USA, pp 2748–2755

Kuroki J, Shinshi T, LichuanLi L et al (2006) Micro-magnetic bearing motor (in Japanese). J Jpn Soc Precis Eng 72–5(2006):662–667

Zeng Z, Jin H, Zhang L et al (2014) Low-voltage and high-performance electrothermal actuator based on multi-walled carbon nanotube/polymer composites. Carbon 84(2015):327–334

Maeda H, Tani K, Suzuki M, Suzuki Y et al (1998) Development of piezoelectric micromotor (in Japenese). Horolog Inst Jpn 42–4(1998):31–39

Sakata M, Komura Y, Seki T et al (1999) Micromachined relay which utilizes single crystal silicon electrostatic actuator, technical digest. In: IEEE international MEMS 99 conference. Twelfth IEEE international conference on micro electro mechanical systems, Orlando, FL, USA, 21 Jan 1999

Fujita H, Actuators M (1988) J Jpn Soc Precis Eng 54–9:13–18

Higuchi T (2002) Prospect of micro actuators. J Jpn Soc Precis Eng 68–5:629–632

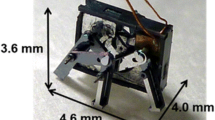

Kawamura S, Tanaka D, Tanaka T et al (2018) Neural networks IC controlled multi-legged walking MEMS robot with independent leg mechanism. Art Life Robot 23(3):380–386

Ken S, Contreras DS, Takeshiro Y et al (2018) Study on silicon device of microrobot system for heterogeneous integration. In: International conference on electronics packaging and iMAPS all Asia conference (ICEP-IAAC), Mie, Japan, 17–21 April 2018

Someya K, Shinozaki H, Sekine Y (1999) Pulse type hardware chaotic neuron model and its bifurcation phenomena. Neural Networks 12:153–161

Saeki K, Nihei D, Tatebe T, Sekine Y (2014) IC implementation of an interstitial cell-based CPG model. Analog Integr Circ Sig Process 81:551–559

Ohara M, Kurosawa M, Sasaki T et al (2019) Development of hardware neural networks ic with switchable gait pattern for insect-type microrobot, 2019 IEEE/SICE international symposium on system integration. Sorbonne Université, Paris, France, pp 663–668

Acknowledgement

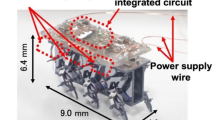

This work was supported by JSPS KAKENHI Grant Number JP18K04060. Also, the part of this research supported by Amano Institute of Technology Public Interest Incorporated Foundation. The fabrication of the microrobot was supported by Research Center for Micro Functional Devices, Nihon University. The VLSI chip (Fig. 1) in this study has been fabricated by Digian Technology, Inc. This work is supported by VLSI Design and Education Center (VDEC), the University of Tokyo in collaboration with Synopsys, Inc., Cadence Design Systems, Inc. and Mentor Graphics, Inc. The VLSI chip in this study has been fabricated in the chip fabrication program of VLSI Design and Education Center (VDEC), the University of Tokyo in collaboration with On-Semiconductor Niigata, and Toppan Printing Corporation. Fabrication of the inchworm motors was supported by the UC Berkeley Marvell Nanofabrication Laboratory. The authors would like to acknowledge the Berkeley Sensor and Actuator Center and the UC Berkeley Swarm Lab for their continued support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

About this article

Cite this article

Sasaki, T., Kurosawa, M., Ohara, M. et al. Development of hardware neural networks generating driving waveform for electrostatic actuator. Artif Life Robotics 25, 446–452 (2020). https://doi.org/10.1007/s10015-020-00608-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10015-020-00608-4