Abstract

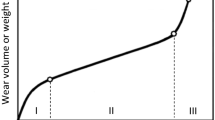

Industrial technology has been significantly developed, and the high performance and precision machines are desired. Friction and wear are the important factors to achieve the development. Mechanical machines consisting of the parts have usually mating surfaces, and friction and wear on the surface affect the product performance and life. Therefore, friction and wear phenomena must be considered at the design stage to design a machine that has long life and high performance. Predicting the surface feature quantitatively and accurately is difficult because the wear phenomena are not cleared yet. There are various methods to predict the worn surfaces, but those methods cannot generate the virtual surfaces randomly. In this study, a generation method of the virtual primary profile curves is proposed in consideration of wear applying wavelet transformation, and the simulated profile curves are verified comparing the actual profiles obtained in actual experiments.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Data availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Bitter JGA (1963) A study of erosion phenomena, part I. Wear 6(3):5–21

Bitter JGA (1963) A study of erosion phenomena, part II. Wear 6(3):169–190

Roco MC, Nair P, Addie GR (1986) Casing headloss in centrifugal slurry pumps. J Fluids Eng ASME 108(4):453–464

Roco MC, Addie GR (1987) Erosion Wear in Slurry Pumps and Pipes. Powder Technol 50(1):35–46

Keng K, Pelow C, Witham L (2008) Analysis of changes in 3D surface texture anisotropy ratio parameter and friction during sheet rolling campaigns. Wear 264:434–438

Wiklund D, Rose BG, Wihlborg A (2009) A friction model evaluated with results from a bending-under-tension test. Tribol Int 42(10):1448–1452

Mezghani S, Zahouani H, Piezanowski JJ (2011) Multiscale characterizations of painted surface appearance by continuous wavelet transform. J Mater Process Technol 211(2):205–211

Wentink DJ, Matthews D, Appelman NM, Toose EM (2015) A generic model for surface texture development, wear and roughness transfer in skin pass rolling. Wear 328–329:167–176

Reizer R, Galda L, Dzierwa A, Pawlus P (2011) Simulation of textured surface topography during a low wear process. Tribol Int 44:1309–1319

Liu L, Yang C, Sheng Y (2018) Wear model based on real-time surface roughness and its effect on lubrication regimes. Tribol Int 126:16–20

ISO 4287 (1997) Geometrical product specifications (GPS)—surface texture: profile method—terms, definitions, and surface texture parameters

ISO 13565-2 (1996) Geometrical product specifications (GPS)—surface texture: profile method; surfaces having stratified functional properties—part 2: height characterization using the linear material ratio curve

Acknowledgements

This study was supported by Japan Society for the Promotion of Science, KAKENHI, Grant Number JP20K04225.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

About this article

Cite this article

Otsuka, A., Hama, R. & Nagata, F. Experimental verification of the wavelet-based surface modeling method considering wear progression process. Artif Life Robotics 28, 618–624 (2023). https://doi.org/10.1007/s10015-023-00876-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10015-023-00876-w