Abstract

In this paper, an automotive spring factory is studied to optimize its hardening process. The assignment of items to the hardening furnace is treated as a one-dimensional cutting stock problem, an approach not found in the literature. To make a feasible decision in this assignment, the activity that follows the furnace, i.e. the bending of the items, is also analyzed. In order to consider practical constraints of the company, as the position of items on the furnace, the proposed mathematical model is based on an arc flow formulation and it is validated through instances with real and random data. A heuristic approach was developed to simulate the company's decision, and to compare the random instances results. Results with real data demonstrate that the model found, in viable computational time, a solution significantly better than that of current company practice, increasing the production by 51.2%. This increase was mainly made possible by a 71.5% reduction in wasted space in the furnace and by a 26.2% reduction of time spent on setups. In random instances, the mathematical model also far outperformed the company's practice, finding the optimal solution in 98.9% of the cases. It was identified that computational time is the most sensitive criterion to the variation in the parameters and the length of the items is the parameter that most influences the results.

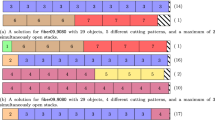

Source: Mecânica Torno e Solda 3 M (2021)

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Data availability

Detailed data, both from the company's actual data instance and from instances with randomly generated data, are available online on the GitHub platform, through the following link. https://github.com/prochavetz/Mathematical-modeling-to-optimize-the-hardening-process-in-a-factory.

References

Aggarwal ML, Agrawal VP, Khan RA (2006) A stress approach model for predictions of fatigue life by shot peening of EN45A spring steel. Int J Fatigue 28(12):1845–1853. https://doi.org/10.1016/j.ijfatigue.2005.12.004

Al-Qureshi HA (2001) Automobile leaf springs from composite materials. J Mater Process Technol 118(1–3):58–61. https://doi.org/10.1016/S0924-0136(01)00863-9

Andrade PRL, de Araujo SA, Cherri AC, Lemos FK (2021) The integrated lot sizing and cutting stock problem in an automotive spring factory. Appl Math Model 91:1023–1036. https://doi.org/10.1016/j.apm.2020.10.033

Ashrafizadeh A, Mehdipour R, Aghanajafi C (2012) A hybrid optimization algorithm for the thermal design of radiant paint cure ovens. Appl Therm Eng 40:56–63. https://doi.org/10.1016/j.applthermaleng.2012.01.062

Banooni S, Hosseinalipour SM, Mujumdar AS, Taherkhani P, Bahiraei M (2009) Baking of flat bread in an impingement oven: modeling and optimization. Drying Technol 27(1):103–112. https://doi.org/10.1080/07373930802565954

Cruz GM, Santos AA, Santos DB (2013) Avaliação das variáveis de processamento de normalização e têmpera dos aços ASTM-516-70N e USI-AR360Q no forno de tratamento térmico 2 da Usiminas. Tecnologia Em Metalurgia, Materiais e Mineração 1(4):6–10. https://doi.org/10.4322/tmm.00104002

Cui Y (2007) Exact algorithm for generating two-segment cutting patterns of punched strips. Appl Math Model 31(9):1865–1873. https://doi.org/10.1016/j.apm.2006.06.010

de Araujo SA, Clark AR (2013) A priori reformulations for joint rolling-horizon scheduling of materials processing and lot-sizing problem. Comput Ind Eng 65(4):577–585. https://doi.org/10.1016/j.cie.2013.04.003

De Souza Amorim FM, Da Silva AM, De Souza Ferreira MP, Toledo CFM (2021) MILP formulation and hybrid evolutionary algorithms for the glass container industry problem with multiple furnaces. Comput Ind Eng 158:107398. https://doi.org/10.1016/j.cie.2021.107398

Furian N, Vössner S (2013) Constrained order packing: comparison of heuristic approaches for a new bin packing problem. CEJOR 21(1):237–264. https://doi.org/10.1007/s10100-011-0228-1

Gilmore PC, Gomory RE (1961) A linear programming approach to the cutting stock problem. Oper Res 9(6):849–859. https://doi.org/10.1287/opre.9.6.849

Gilmore PC, Gomory RE (1963) A linear programming approach to the cutting stock problem–Part II. Oper Res 11(6):863–888. https://doi.org/10.1287/opre.11.6.863

Glick N, Shareef I (2019) Optimization of electrostatic powder coat cure oven process: a capstone senior design research project. Procedia Manufacturing 34:1018–1029. https://doi.org/10.1016/j.promfg.2019.06.093

Gramani MCN, França PM, Arenales MN (2009) A Lagrangian relaxation approach to a coupled lot-sizing and cutting stock problem. Int J Prod Econ 119(2):219–227. https://doi.org/10.1016/j.ijpe.2009.02.011

Gramani MCN, França PM, Arenales MN (2011) A linear optimization approach to the combined production planning model. J Franklin Inst 348(7):1523–1536. https://doi.org/10.1016/j.jfranklin.2010.05.010

Han S, Kim S, Kim YT, Kwak G, Kim J (2019) Optimization-based assessment framework for carbon utilization strategies: Energy production from coke oven gas. Energy Convers Manage 187:1–14. https://doi.org/10.1016/j.enconman.2019.03.007

Hinxman AI (1980) The trim-loss and assortment problems: a survey. Eur J Oper Res 5(1):8–18. https://doi.org/10.1016/0377-2217(80)90068-5

Johnson DS (1974) Fast algorithms for bin packing. J Comput Syst Sci 8(3):272–314. https://doi.org/10.1016/S0022-0000(74)80026-7

Kaiser B, Pyttel B, Berger C (2011) VHCF-behavior of helical compression springs made of different materials. Int J Fatigue 33(1):23–32. https://doi.org/10.1016/j.ijfatigue.2010.04.009

Kantorovich LV (1960) Mathematical methods of organizing and planning production. Manage Sci 6(4):366–422. https://doi.org/10.1287/mnsc.6.4.366

Kierkosz I, Luczak M (2014) A hybrid evolutionary algorithm for the two-dimensional packing problem. CEJOR 22(4):729–753. https://doi.org/10.1007/s10100-013-0300-0

Kong KW, Ismail A, Tan CP, Rajab NF (2010) Optimization of oven drying conditions for lycopene content and lipophilic antioxidant capacity in a by-product of the pink guava puree industry using response surface methodology. LWT-Food Sci Technol 43(5):729–735. https://doi.org/10.1016/j.lwt.2009.10.011

Leão AAS, Furlan MM, Toledo FMB (2017) Decomposition methods for the lot-sizing and cutting-stock problems in paper industries. Appl Math Model 48:250–268. https://doi.org/10.1016/j.apm.2017.04.010

Lei Q, Wu M, Liu G (2017) Optimization oriented performance assessment for combustion process of coke oven. IFAC-Papers OnLine 50(1):13778–13783. https://doi.org/10.1016/j.ifacol.2017.08.2573

Luo RK, Wu WX, Mortel WJ (2005) A method to predict the heat generation in a rubber spring used in the railway industry. Procee Inst Mech Eng Part f: J Rail Rapid Transit 219(4):239–244. https://doi.org/10.1243/095440905X8862

Mack D, Bortfeldt A (2012) A heuristic for solving large bin packing problems in two and three dimensions. CEJOR 20(2):337–354. https://doi.org/10.1007/s10100-010-0184-1

Mula J, Bogataj M (2021) OR in the industrial engineering of Industry 4.0: experiences from the Iberian Peninsula mirrored in CJOR. CEJOR 29:1163–1184. https://doi.org/10.1007/s10100-021-00740-x

Omolola AO, Jideani AIO, Kapila PF, Jideani VA (2018) Optimization of oven drying conditions of banana (Musa spp., aaa group, cv ‘Luvhele’and ‘Mabonde’) using response surface methodology. Agrociencia 52(4):539–551

Özden S, Kiliç F (2020) Performance evaluation of GSA, SOS, ABC and ANN algorithms on linear and quadratic modelling of eggplant drying kinetic. Food Sci Technol 40(3):635–643. https://doi.org/10.1590/fst.12719

Pask F, Sadhukhan J, Lake P, Mckenna S, Perez EB, Yang A (2014) Systematic approach to industrial oven optimization for energy saving. Appl Therm Eng 71(1):72–77. https://doi.org/10.1016/j.applthermaleng.2014.06.013

Peng TK, Trappey AJC (1996) CAD-integrated engineering-data-management system for spring design. Robotics Comput-Integr Manuf 12(3):271–281. https://doi.org/10.1016/0736-5845(96)00011-7

Penha RN, Vendramim JC, Canale, LCF (2011) Tensões residuais térmicas obtidas da têmpera a vácuo do aço ferramenta AISI H13. In: X Congresso Ibero-Americano em Engenharia Mecânica (CIBIM 10). Porto, Portugal

Pimenta CD, Silva MB, Salomon VAP, Penteado RB, Gomes FM (2015) Aplicação das metodologias Desirability e Simplex para otimização das propriedades mecânicas em arames de aço temperados. Production 25(3):598–610. https://doi.org/10.1590/0103-6513.094812

Pimenta CD, Silva MB, Costa AFB, Salomon VAP (2016) Otimização e escolha de modelos probabilísticos no processo de tratamento térmico em arames de aço temperados e revenidos. Revista Eletrôn Produção e Eng 8(1):640–652. https://doi.org/10.18407/issn.1983-9952.2016.v8.n1.p640-652

Poldi KC, de Araujo SA (2016) Mathematical models and a heuristic method for the multiperiod one-dimensional cutting stock problem. Ann Oper Res 238(1–2):497–520. https://doi.org/10.1007/s10479-015-2103-2

Poltroniere SC, Poldi KC, Toledo FMB, Arenales MN (2008) A coupling cutting stock-lot sizing problem in the paper industry. Annals Op Res 157(1):91–104. https://doi.org/10.1007/s10479-007-0200-6

Silva EM, Melega GM, Akartunali K, de Araujo SA (2022) Formulations and theoretical analysis of the one-dimensional multi-period cutting stock problem with setup costs. Eur J Op Res (accepted). https://doi.org/10.1016/j.ejor.2022.04.023

Tomat L, Gradišar M (2017) One-dimensional stock cutting: optimization of usable leftovers in consecutive orders. CEJOR 25:473–489. https://doi.org/10.1007/s10100-017-0466-y

Mecânica Torno e Solda 3M (2021) Retrieved from: https://www.agbrasil360.com.br/mecanica3m/49-produto-feixe-de-molas-de-caminhao-juruena-mt. Accessed on: 11/01/2021

Uribetxebarria U, Garmendia A, Elorza U (2021) Does employee participation matter? An empirical study on the effects of participation on well-being and organizational performance. CEJOR 29:1397–1425. https://doi.org/10.1007/s10100-020-00704-7

Valério De Carvalho JM (2002) LP models for bin packing and cutting stock problems. Eur J Oper Res 141:253–273. https://doi.org/10.1016/S0377-2217(02)00124-8

Vanzela M, Melega GM, Rangel S, de Araujo SA (2017) The integrated lot sizing and cutting stock problem with saw cycle constraints applied to furniture production. Comput Oper Res 79:148–160. https://doi.org/10.1016/j.cor.2016.10.015

Wascher G, Gau T (1996) Heuristics for the integer one-dimensional cutting stock problem: a computational study. Op-Res-Spektrum 18(3):131–144

Wolsey LA (1977) Valid inequalities, covering problems and discrete dynamic programs. Ann Discrete Math 1:527–538. https://doi.org/10.1016/S0167-5060(08)70758-1

Yang Z, Naeem W, Menary G, Deng J, Li K (2014) Advanced modelling and optimization of infared oven in injection stretch blow-moulding for energy saving. IFAC Proc Vol 47(3):766–771. https://doi.org/10.3182/20140824-6-ZA-1003.01191

Acknowledgements

The autors would like to thank Universidade Tecnológica Federal do Paraná (UTFPR), Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPq) (Process numbers 421130/2018-0, 305261/2018-5, 306558/2018-1 and 406335/2018-4) and Fundação de Amparo a Pesquisa do Estado de São Paulo (FAPESP) (Process numbers 2013/07375-0 and 2016/01860-1) for the support on this work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no competing interests to declare that are relevant to the content of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

de Lara Andrade, P.R., de Araujo, S.A., Cherri, A.C. et al. The cutting stock problem applied to the hardening process in an automotive spring factory. Cent Eur J Oper Res 31, 637–664 (2023). https://doi.org/10.1007/s10100-022-00826-0

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10100-022-00826-0