Abstract

With the rapid changes in the global business environment, enterprises face many risks for their supply chains. The development of blockchain technology (BCT), an emerging technology, could transform supply chain activities and provides an opportunity to mitigate supply chain risks (SCRs). However, there is a lack of guidance on this issue. Therefore, this study evaluates and prioritizes the impacts of BCT on reducing SCRs. By applying the analytic hierarchy process (AHP) approach, this study identifies and assesses the nineteen BCT adoption enablers for reducing SCRs in a hierarchical structure. Results show that the sourcing process is the essential enabler when enterprises consider adopting BCT for reducing risks, and the weight of the making process is ranked second. Among the sub-criteria, the top five items are clarity of supply sources, counterfeit and shoddy products, fraud in contract fulfillment, the flexibility of capacity, and sensitivity to demand change. This study's findings may guide practitioners considering the introduction of BCT to reduce SCRs and for scholars who are developing related theories.

Similar content being viewed by others

References

Abeyratne SA, Monfared RP (2016) Blockchain ready manufacturing supply chain using distributed ledger. Int J Res Eng Technol 5(9):1–10. https://doi.org/10.15623/ijret.2016.0509001

Adeseun MA, Anosike AI, Reyes JAG, Al-Talib M (2018) Supply chain risk perception: understanding the gap between theory and practice. IFAC-PapersOnLine 51(11):1701–1706. https://doi.org/10.1016/j.ifacol.2018.08.211

Afzal MA (2011) Managing risk and resilience in supply chain and 3pl: conceptual developments and proposed frameworks. King Fahd University of Petroleum and Minerals, Dhahran

Akarte M, Surendra N, Ravi B, Rangaraj N (2001) Web-based casting supplier evaluation using analytical hierarchy process. J Oper Res Soc 52(5):511–522. https://doi.org/10.1057/palgrave.jors.2601124

Blockgeeks (2017) Smart contracts: the blockchain technology that will replace lawyers. https://blockgeeks.com/guides/smart-contracts/. Retrieved 07 Jan 2021

Casey MJ, Wong P (2017) Global supply chains are about to get better, thanks to blockchain. https://hbr.org/2017/03/global-supply-chains-are-about-to-get-better-thanks-to-blockchain. Retrieved 7 Oct 2018

Cavinato JL (2004) Supply chain logistics risks: from the back room to the board room. Int J Phys Distrib Logist Manag 34(5):383–387. https://doi.org/10.1108/09600030410545427

Chan F, Chan H, Ip R, Lau H (2007) A decision support system for supplier selection in the airline industry. Proc Inst Mech Eng B J Eng Manuf 221(4):741–758. https://doi.org/10.1243/09544054JEM629

Chan FS (2003) Interactive selection model for supplier selection process: an analytical hierarchy process approach. Int J Prod Res 41(15):3549–3579. https://doi.org/10.1080/0020754031000138358

Chan FT, Chan H (2004) Development of the supplier selection model—a case study in the advanced technology industry. Proc Inst Mech Eng B J Eng Manuf 218(12):1807–1824. https://doi.org/10.1177/095440540421801213

Chang SE, Chen Y-C, Lu M-F (2019) Supply chain re-engineering using blockchain technology: a case of smart contract-based tracking process. Technol Forecast Soc Change 144(July):1–11. https://doi.org/10.1016/j.techfore.2019.03.015

Che Z, Wang H, Sha D (2007) A multi-criterion interaction-oriented model with proportional rule for designing supply chain networks. Expert Syst Appl 33(4):1042–1053. https://doi.org/10.1016/j.eswa.2006.08.015

Christopher M (1999) Logistics and supply chain management: strategies for reducing cost and improving service, second edition. Int J Logist Res Appl 2(1):103–104. https://doi.org/10.1080/13675569908901575

Christopher, M., Peck, H., Rutherford, C., & Jüttner, U. (2003). Understanding Supply Chain Risk: A Self-Assessment Workbook. Retrieved 14 May, 2020, from http://hdl.handle.net/1826/4373

Colicchia C, Strozzi F (2012) Supply chain risk management: a new methodology for a systematic literature review. Supply Chain Manag Int J 17(4):403–418. https://doi.org/10.1108/13598541211246558

DHL (2018) Blockchain in logistics: customer solutions & innovation. https://www.logistics.dhl/content/dam/dhl/global/core/documents/pdf/glo-core-blockchain-trend-report.pdf. Retrieved 10 Oct 2018

Eyefortransport (2017) 2017 Supply chain trends recap. https://www.reutersevents.com/supplychain/content/2017-supply-chain-trends-recap. Retrieved 18 Nov 18

Fallahpour M, Shirmohammadi S, Semsarzadeh M, Zhao J (2014) Tampering detection in compressed digital video using watermarking. IEEE Trans Instrum Meas 63(5):1057–1072. https://doi.org/10.1109/TIM.2014.2299371

Fan Y, Stevenson M (2018) A review of supply chain risk management: definition, theory, and research agenda. Int J Phys Distrib Logist Manag 48(3):205–230. https://doi.org/10.1108/IJPDLM-01-2017-0043

Feng Q, He D, Zeadally S, Khan MK, Kumar N (2019) A survey on privacy protection in blockchain system. J Netw Comput Appl 126(5):45–58. https://doi.org/10.1016/j.jnca.2018.10.020

Gaudenzi B, Borghesi A (2006) Managing risks in the supply chain using the AHP method. Int J Logist Manag Decis 17(1):114–136. https://doi.org/10.1108/09574090610663464

Ghode D, Yadav V, Jain R, Soni G (2020) Adoption of blockchain in supply chain: an analysis of influencing factors. J Enterp Inf Manag 33(3):437–456. https://doi.org/10.1108/JEIM-07-2019-0186

Govindan K, Chaudhuri A (2016) Interrelationships of risks faced by third party logistics service providers: a dematel based approach. Transp Res E Logist Transp Rev 90(June):177–195. https://doi.org/10.1016/j.tre.2015.11.010

Green A (2017) Will blockchain accelerate trade flows? https://www.ft.com/content/a36399fa-a927-11e7-ab66-21cc87a2edde. Retrieved 19 Nov 2019

Hachicha W, Elmsalmi M (2014) An integrated approach based-structural modeling for risk prioritization in supply network management. J Risk Res 17(10):1301–1324. https://doi.org/10.1080/13669877.2013.841734

Hackett R (2017) Maersk and microsoft tested a blockchain for shipping insurance. https://fortune.com/2017/09/05/maersk-blockchain-insurance/. Retrieved 11 Nov 2019

Heutger M, Kückelhaus M (2018) Blockchain in logistics. https://www.logistics.dhl/content/dam/dhl/global/core/documents/pdf/glo-core-blockchain-trend-report.pdf. Retrieved 4 Sept 2018

Ho W, Zheng T, Yildiz H, Talluri S (2015) Supply chain risk management: a literature review. Int J Prod Res 53(16):5031–5069. https://doi.org/10.1080/00207543.2015.1030467

Hofmann E, Strewe UM, Bosia N (2017) Supply chain finance and blockchain technology: the case of reverse securitisation, 1st edn. Springer, Bern

Hou J, Su D (2007) EJB-MVC oriented supplier selection system for mass customization. J Manuf Technol Manag 18(1):54–71. https://doi.org/10.1108/17410380710717643

Jüttner U, Peck H, Christopher M (2003) Supply chain risk management: outlining an agenda for future research. Int J Logist Res Appl 6(4):197–210. https://doi.org/10.1080/13675560310001627016

Jayant A (2017) An analytical hierarchy process (AHP) based approach for supplier selection: an automotive industry case study. Int J Bus Insights Transform 11(1):102–114

Kamath R (2018) Food traceability on blockchain: Walmart’s Pork and Mango Pilots with IBM. J Br Blockchain Assoc 1(1):1–12. https://doi.org/10.31585/jbba-1-1-(10)2018

Koh S, Gunasekaran A (2006) Performance prediction using supply chain uncertainty modelling. Int J Serv Oper Manag 2(3):279–293. https://doi.org/10.1504/IJSOM.2006.009861

Korpela J, Tuominen M (1996) A decision aid in warehouse site selection. Int J Prod Econ 45(1–3):169–180. https://doi.org/10.1016/0925-5273(95)00135-2

Kshetri N (2018) 1 blockchain’s roles in meeting key supply chain management objectives. Int J Inf Manag 19:80–89. https://doi.org/10.1016/j.ijinfomgt.2017.12.005

Kull T, Closs D (2008) The risk of second-tier supplier failures in serial supply chains: implications for order policies and distributor autonomy. Eur J Oper Res 186(3):1158–1174. https://doi.org/10.1016/j.ejor.2007.02.028

Kumar V, Bak O, Guo R, Garza-Reyes JA, Kumari A (2018) An empirical analysis of supply and manufacturing risk and business performance: a chinese manufacturing supply chain perspective. Supply Chain Manag Int J 23(6):461–479. https://doi.org/10.1108/SCM-10-2017-0319

Lastovetska A (2020). Blockchain architecture basics: components, structure, benefits & creation. https://mlsdev.com/blog/156-how-to-build-your-own-blockchain-architecture. Retrieved 19 Nov 2020

Liu F-HF, Hai HL (2005) The voting analytic hierarchy process method for selecting supplier. Int J Prod Econ 97(3):308–317. https://doi.org/10.1016/j.ijpe.2004.09.005

Luthra S, Mangla SK, Xu L, Diabat A (2016) Using AHP to evaluate barriers in adopting sustainable consumption and production initiatives in a supply chain. Int J Prod Econ 181(Part B), 342–349. https://doi.org/10.1016/j.ijpe.2016.04.001

Makhdoom I, Abolhasan M, Abbas H, Ni W (2018) Blockchain’s adoption in IoT: the challenges, and a way forward. J Netw Comput Appl 125(January):251–279. https://doi.org/10.1016/j.jnca.2018.10.019

Manuj I, Mentzer JT (2008) Global supply chain risk management strategies. Int J Phys Distrib Logist Manag 38(3):192–223. https://doi.org/10.1108/09600030810866986

Millet I, Wedley WC (2002) Modeling risk and uncertainty with the analytic hierarchy process. J Multi-Criteria Decis Anal 11(2):97–107. https://doi.org/10.1002/mcda.319

Min H (2019) Blockchain technology for enhancing supply chain resilience. Bus Horizons 62(1):35–45. https://doi.org/10.1016/j.bushor.2018.08.012

Mu E, Carroll J (2016) Development of a fraud risk decision model for prioritizing fraud risk cases in manufacturing firms. Int J Prod Econ 173(March):30–42. https://doi.org/10.1016/j.ijpe.2015.11.014

Muralidharan C, Anantharaman N, Deshmukh S (2002) A multi-criteria group decisionmaking model for supplier rating. J Supply Chain Manag 38(3):22–33. https://doi.org/10.1111/j.1745-493X.2002.tb00140.x

Nakamoto S (2008) Bitcoin: a peer-to-peer electronic cash system. https://bitcoin.org/bitcoin.pdf. Retrieved 12 Oct 2018

Partovi FY, Burton J, Banerjee A (1990) Application of analytical hierarchy process in operations management. Int J Oper Prod Manag 10(3):5–19. https://doi.org/10.1108/01443579010134945

Peng Y, Kou G, Wang G, Wu W, Shi Y (2011) Ensemble of software defect predictors: an AHP-based evaluation method. Int J Inf Technol Decis Mak 10(01):187–206. https://doi.org/10.1142/S0219622011004282

Radivojević G, Gajović V (2014) Supply chain risk modeling by AHP and fuzzy AHP methods. J Risk Res 17(3):337–352. https://doi.org/10.1080/13669877.2013.808689

Rangel DA, de Oliveira TK, Leite MSA (2015) Supply chain risk classification: discussion and proposal. Int J Prod Res 53(22):6868–6887. https://doi.org/10.1080/00207543.2014.910620

Rao S, Goldsby TJ (2009) Supply chain risks: a review and typology. Int J Logist Manag 20(1):97–123. https://doi.org/10.1108/09574090910954864

Reyna A, Martín C, Chen J, Soler E, Díaz M (2018) On blockchain and its integration with IoT. Challenges and opportunities. Fut Gener Comput Syst 88:73–190. https://doi.org/10.1016/j.future.2018.05.046

Rotaru K, Wilkin C, Ceglowski A (2014) Analysis of SCOR’s approach to supply chain risk management. Int J Oper Prod Manag 34(10):1246–1268. https://doi.org/10.1108/IJOPM-09-2012-0385

Saaty TL (1980) The analytic hierarchy process: planning, priority setting, resources allocation. McGraw-Hill, New York

Saaty TL (1990) The analytic hierarchy process in conflict management. Int J Confl Manag 1(1):47–68. https://doi.org/10.1108/eb022672

Saaty TL (1994) Fundamentals of decision making with the analytic hierarchy process. RWS Publications, Pittsburgh

Saban K, Mawhinney JR, Drake MJ (2017) An integrated approach to managing extended supply chain networks. Bus Horizons 60(5):689–697. https://doi.org/10.1016/j.bushor.2017.05.012

Saberi S, Kouhizadeh M, Sarkis J, Shen L (2019) Blockchain technology and its relationships to sustainable supply chain management. Int J Prod Res 57(7):2117–2135. https://doi.org/10.1080/00207543.2018.1533261

Samvedi A, Jain V, Chan FT (2013) Quantifying risks in a supply chain through integration of fuzzy AHP and fuzzy TOPSIS. Int J Prod Res 51(8):2433–2442. https://doi.org/10.1080/00207543.2012.741330

Schoenherr T, Tummala VR, Harrison TP (2008) Assessing supply chain risks with the analytic hierarchy process: providing decision support for the offshoring decision by a US manufacturing company. J Purchas Supply Manag 14(2):100–111. https://doi.org/10.1016/j.pursup.2008.01.008

Shi D (2014) A review of enterprise supply chain risk management. J Syst Sci Syst Eng 13(2):219–244. https://doi.org/10.1007/s11518-006-0162-2

Sissman M, Sharma K (2018) Building supply management with blockchain. ISE Ind Syst Eng Work 50(7):43–46

Sáenz MJ, Revilla E, Acero B (2018) Aligning supply chain design for boosting resilience. Bus Horizons 61(3):443–452. https://doi.org/10.1016/j.bushor.2018.01.009

Sodhi MS, Son BG, Tang CS (2012) Researcher’ perspectives on supply chain risk management. Prod Oper Manag 21(1):1–13. https://doi.org/10.1111/j.1937-5956.2011.01251.x

Sreedevi R, Saranga H (2017) Uncertainty and supply chain risk: the moderating role of supply chain flexibility in risk mitigation. Int J Prod Econ 193(November):332–342. https://doi.org/10.1016/j.ijpe.2017.07.024

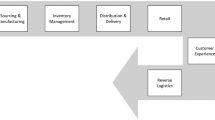

Supply Chain Council (2010) Supply chain operations reference (SCOR) model: Overview Version 10.0.

Toyoda K, Mathiopoulos PT, Sasase I, Ohtsuki T (2017) A novel blockchain-based product ownership management system (POMS) for anti-counterfeits in the post supply chain. IEEE Access 5:17465–17477. https://doi.org/10.1109/ACCESS.2017.2720760

Truong HQ, Hara Y (2018) Supply chain risk management: manufacturing- and service-oriented firms. J Manuf Technol Manag 29(2):218–239

Tse D, Zhang B, Yang Y, Cheng C, Mu H (2017) Blockchain application in food supply information security. In: 2017 IEEE International Conference on Industrial Engineering and Engineering management (IEEM), Singapore

Tummala R, Schoenherr T (2011) Assessing and managing risks using the supply chain risk management process (SCRMP). Supply Chain Manag Int J 16(6):474–483. https://doi.org/10.1108/13598541111171165

Venkatesan SP, Kumanan S (2012) Supply chain risk prioritisation using a hybrid AHP and PROMETHEE approach. Int J Serv Oper Manag 13(1):19–41. https://doi.org/10.1504/IJSOM.2012.048274

Viriyasitavat W, Hoonsopon D (2019) Blockchain characteristics and consensus in modern business processes. J Ind Inf Integr 13(March):32–39. https://doi.org/10.1016/j.jii.2018.07.004

Visconti RM (2019) Blockchain valuation: internet of value, digital networks and smart transactions. https://www.researchgate.net/publication/329916782. Retrieved 18 Nov 2019

Wamba SF, Queiroz MM, Trinchera L (2020) Dynamics between blockchain adoption determinants and supply chain performance: an empirical investigation. Int J Prod Econ 229:107791. https://doi.org/10.1016/j.ijpe.2020.107791

Wang G, Qin L, Li G, Chen L (2009) Landfill site selection using spatial information technologies and AHP: a case study in Beijing. China J Environ Manag 90(8):2414–2421. https://doi.org/10.1016/j.jenvman.2008.12.008

Wang H, Che Z, Wu C (2010) Using analytic hierarchy process and particle swarm optimization algorithm for evaluating product plans. Expert Syst Appl 37(2):1023–1034. https://doi.org/10.1016/j.eswa.2009.05.073

White M (2018) Digitizing global trade with Maersk and IBM. https://www.ibm.com/blogs/blockchain/2018/01/digitizing-global-trade-maersk-ibm/. Retrieved 2019

Wolfson R (2018) Understanding how IBM and others use blockchain technology to track global food supply chain. https://www.forbes.com/sites/rachelwolfson/2018/07/11/understanding-how-ibm-and-others-use-blockchain-technology-to-track-global-food-supply-chain/?sh=6e986b102d1e. Retrieved 11 Nov 2019

Yang J, Lee H (1997) An AHP decision model for facility location selection. Facilities 15(9/10):241–254. https://doi.org/10.1108/02632779710178785

Zahedi F (1986) The analytic hierarchy process—a survey of the method and its applications. Interfaces 16(4):96–108. https://doi.org/10.1287/inte.16.4.96

Zheng Z, Xie S, Dai H, Chen X, Wang H (2017) An overview of blockchain technology: architecture, consensus, and future trends. In: IEEE International Congress on Big Data, Boston, MA

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

Evaluation criteria and description used in this study.

Criteria |

|---|

Planning (P) |

P1 Transparency of operational goals: Using blockchain could reduce opacity risks to company goals, including operational goals, strategies, and risks that affect business strategy |

P2 Flexible capacity: Using blockchain could reduce the risks of poor capacity planning, such as overproduction or underutilization |

P3 Sensitivity to demand change: Using blockchain could reduce the risks of low upstream and downstream demand forecasts and insensitivity to changes |

Sourcing (S) |

S1 Clarity of the supply source: Using blockchain could reduce the risk of unknown sources of supply |

S2 Fraud or misunderstanding of contract fulfillment: Using the blockchain, e.g., smart contracts, could reduce the risk of contract fraud or misunderstandings among supply chain members |

S3 Accounting audit and payment security: Using blockchain could reduce the risk of accounting audit and payment security |

S4 Inter-vendor visibility: Using blockchain could reduce the risk of mistrust caused by poor information sharing between suppliers |

Making (M) |

M1 Disruption crisis identification: Using the blockchain's traceability could identify the source of a crisis or defect and reduce the risk of supply chain disruptions caused by natural disasters, human factors, political and economic instability |

M2 The integration of production information: Using blockchain could reduce the risk of unintegrated production information |

M3 Timeliness of production information: Using the blockchain could reduce the risk that product information cannot be updated in real-time |

M4 Counterfeit and shoddy products: Using blockchain could reduce the risks of counterfeit and shoddy products |

Delivery (D) |

D1 Tampering with shipping labels or transaction records: Using blockchain could reduce the risk of tampering with shipping labels or transaction records |

D2 Misplaced or lost goods: Using blockchain could reduce the risk of goods being misplaced or lost |

D3 Verifiability of goods and services: Using the blockchain could reduce the risks arising from the inability to verify goods and services' correctness |

D4 Transparency and efficiency of the order fulfillment process: Using blockchain could reduce the risk of opaque and inefficient order fulfillment processes |

Return and others (R) |

R1 Intervened or manipulated by middlemen: Using blockchain could reduce the risk of interference or manipulation by intermediaries such as governments, banks, and other intermediaries |

R2 Cybercrime and Hacking: Using blockchain could reduce the risk of cybercrime and hacking |

R3 Manual processing error: Using the blockchain's traceability could reduce the risk of manual input or validation errors |

R4 Paper documents processing error: Use blockchain-verifiable digital records could reduce the risks associated with processing paper documents |

Rights and permissions

About this article

Cite this article

Lai, JY., Wang, J. & Chiu, YH. Evaluating blockchain technology for reducing supply chain risks. Inf Syst E-Bus Manage 19, 1089–1111 (2021). https://doi.org/10.1007/s10257-021-00533-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10257-021-00533-4