Abstract

This paper studies the optimization of the joint selective maintenance and repairperson assignment problem when the quality of maintenance actions is uncertain, thus leading to uncertain post-maintenance reliability of system components. This situation is common in practice since maintenance actions are never perfect and are affected by several factors such as the qualification and the degree of expertise of the repairpersons, the maintenance methods and tools used, and naturally occurring operating environment variability. Using a robust optimization framework, the maintenance quality uncertainty is captured via non-symmetric budget uncertainty sets that enable the level of decision-maker conservatism to be controlled. Both the nominal (i.e., deterministic) and robust problems are reformulated as mixed-integer exponential conic programs that can be solved using currently available solvers. Extensive numerical experiments on benchmark instances show the favorable computational performance of the proposed reformulations and the value of considering maintenance quality uncertainty when developing selective maintenance plans.

Similar content being viewed by others

Data availability

The data that support the findings of this study are available from the corresponding author upon request.

References

Ahadi K, Sullivan KM (2019) Approximate dynamic programming for selective maintenance in series–parallel systems. IEEE Trans Reliab 69(3):1147–1164

Al-Jabouri H, Saif A, Khatab A, et al. (2022) Selective maintenance optimization: a condensed critical review and future research directions. In: 10th IFAC-PapersOnLine, IFAC conference on manufacturing modelling management and control MIM 2022, pp 1213–1218

Al-Jabouri H, Saif A, Diallo C et al. (2023) Branch-and-price algorithms for large-scale mission-oriented maintenance planning problems. Comput Oper Res 153(106):191

Ben-Tal A, Den Hertog D, Vial JP (2015) Deriving robust counterparts of nonlinear uncertain inequalities. Math Program 149(1):265–299

Bertsimas D, Sim M (2004) The price of robustness. Oper Res 52(1):35–53

Cao W, Song W, Hu Q, et al. (2016) An exact method for solving selective maintenance problems considering imperfect maintenance. In: 2016 International conference on intelligent networking and collaborative systems (INCoS), pp 522–526

Cao W, Jia X, Hu Q et al. (2018) A literature review on selective maintenance for multi-unit systems. Qual Reliab Eng Int 34(5):824–845

Cao W, Jia X, Liu Y et al. (2018) Selective maintenance optimization for fuzzy multi-state systems. J Intell Fuzzy Syst 34(1):105–121

Cassady CR, Murdock WP Jr, Pohl EA (2001) Selective maintenance for support equipment involving multiple maintenance actions. Eur J Oper Res 129(2):252–258

Chaabane K, Khatab A, Diallo C et al. (2020) Integrated imperfect multimission selective maintenance and repairpersons assignment problem. Reliab Eng Syst Saf 199(106):895

Chen Z, He Y, Zhao Y et al. (2019) Mission reliability-oriented selective maintenance optimization for intelligent multistate manufacturing systems with uncertain maintenance quality. IEEE Access 7:109804–109816

Dao CD, Zuo MJ, Pandey M (2014) Selective maintenance for multi-state series-parallel systems under economic dependence. Reliab Eng Syst Saf 121:240–249

Diallo C, Venkatadri U, Khatab A et al. (2018) Optimal selective maintenance decisions for large serial k-out-of-n: G systems under imperfect maintenance. Reliab Eng Syst Saf 175:234–245

Diallo C, Venkatadri U, Khatab A et al. (2019) Optimal joint selective imperfect maintenance and multiple repairpersons assignment strategy for complex multicomponent systems. Int J Prod Res 57(13):4098–4117

Galante GM, La Fata CM, Lupo T et al. (2020) Handling the epistemic uncertainty in the selective maintenance problem. Comput Ind Eng 141(106):293

Ghorbani M, Nourelfath M, Gendreau M (2022) A two-stage stochastic programming model for selective maintenance optimization. Reliab Eng Syst Saf 223(108):480

Ikonen TJ, Mostafaei H, Ye Y et al. (2020) Large-scale selective maintenance optimization using bathtub-shaped failure rates. Comput Chem Eng 139(106):876

Jia X, Cao W, Hu Q (2019) Selective maintenance optimization for random phased-mission systems subject to random common cause failures. Proc Inst Mech Eng Part O J Risk Reliab 233(3):379–400

Jiang T, Liu Y (2020) Robust selective maintenance strategy under imperfect observations: a multi-objective perspective. IISE Trans 52(7):751–768

Jiang T, Liu Y (2020) Selective maintenance strategy for systems executing multiple consecutive missions with uncertainty. Reliab Eng Syst Saf 193(106):632

Khatab A, Aghezzaf EH (2016) Selective maintenance optimization when quality of imperfect maintenance actions are stochastic. Reliab Eng Syst Saf 150:182–189

Khatab A, Ait-Kadi D, Nourelfath M (2007) Heuristic-based methods for solving the selective maintenance problem for series-parallel systems. In: International conference on industrial engineering and systems management, Beijing, pp 333–334

Khatab A, Ait-Kadi D, Artiba A (2008) Simulated annealing method for the selective maintenance optimization of multi-mission series-parallel systems. In: Proceedings of the joint ESREL (European Safety and Reliability) and SRA-Europe (Society for Risk Analysis Europe) conference, pp 641–647

Khatab A, Aghezzaf EH, Diallo C et al. (2017) Selective maintenance optimisation for series-parallel systems alternating missions and scheduled breaks with stochastic durations. Int J Prod Res 55(10):3008–3024

Khatab A, Diallo C, Venkatadri U et al. (2018) Optimization of the joint selective maintenance and repairperson assignment problem under imperfect maintenance. Comput Ind Eng 125:413–422

Lan P, Lin M, Naichao W (2017) A fleet-level selective maintenance model for long-distance highway transportation considering stochastic repair quality. In: 2017 2nd International conference on system reliability and safety (ICSRS), pp 348–353

Lust T, Roux O, Riane F (2009) Exact and heuristic methods for the selective maintenance problem. Eur J Oper Res 197(3):1166–1177

Malik MAK (1979) Reliable preventive maintenance scheduling. AIIE Trans 11(3):221–228

Miettinen K (1999) Nonlinear multiobjective optimization, vol 12. Springer

Mosek APS (2021) Mosek modeling cookbook. https://docs.mosek.com/MOSEKModelingCookbook-a4paper.pdf, online. Accessed 2 May 2022

Pandey M, Zuo MJ (2014) Selective maintenance considering two types of failure modes. Int J Strateg Eng Asset Manag 19 2(1):37–62

Pandey M, Zuo MJ, Moghaddass R et al. (2013) Selective maintenance for binary systems under imperfect repair. Reliab Eng Syst Saf 113:42–51

Rajagopalan R, Cassady R (2006) An improved selective maintenance solution approach. J Qual Maint Eng

Rice WF (1999) Optimal selective maintenance decisions for series systems. PhD thesis, Mississippi State University. Department of Industrial Engineering

Rice W, Cassady C, Nachlas J (1998) Optimal maintenance plans under limited maintenance time. In: Proceedings of the seventh industrial engineering research conference, pp 1–3

Shahraki AF, Yadav OP, Vogiatzis C (2020) Selective maintenance optimization for multi-state systems considering stochastically dependent components and stochastic imperfect maintenance actions. Reliab Eng Syst Saf 196(106):738

Su C, Huang K, Wen Z (2022) Multi-objective imperfect selective maintenance optimization for series–parallel systems with stochastic mission duration. Proc Inst Mech Eng Part O J Risk Reliab 236(6):923–935

Wang Y, Elahi E, Xu L (2019) Selective maintenance optimization modelling for multi-state deterioration systems considering imperfect maintenance. IEEE Access 7:62759–62768. https://doi.org/10.1109/ACCESS.2019.2916624

Xu Q, Guo L, Wang N et al. (2015) Recent advances in selective maintenance from 1998 to 2014. J Donghua Univ Engl Ed 32(6):986–994

Ye Q, Xie W (2021) Second-order conic and polyhedral approximations of the exponential cone: application to mixed-integer exponential conic programs. arXiv:2106.09123

Zhang L, Zhang L, Shan H et al. (2019) Selective maintenance planning considering team capability based on fuzzy integral and dynamic artificial bee colony algorithm. IEEE Access 7:66553–66566

Zhao Z, Yan X, Xiao B, et al. (2018) Selective maintenance modeling for a multi-state system considering human reliability. In: 2018 3rd International conference on system reliability and safety (ICSRS). IEEE, pp 346–352

Funding

No funding was received for conducting this study

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix 1: Two-phase approach

Appendix 1: Two-phase approach

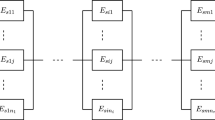

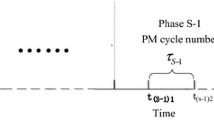

Diallo et al. (2019) devised a decomposition method to represent the JSM-RAP as a binary integer program (BIP). In the first phase, a methodical and structured approach generates an exhaustive set of patterns containing all potential combinations of components, repairpersons, and maintenance levels. The second phase focuses on solving a BIP (demonstrated below) that optimizes the choice of a sequence of patterns, aiming to maximize system reliability.

where \(i \in \left\{ 1, \dots , I\right\}\) is the index of the subsystems, \(p \in \left\{ 1, \dots ,\ P_{i}\right\}\) is the index of patterns generated for subsystem i, \(C_{0}\) is the maintenance budget available, \(D_{0}\) is the break duration, \(T_{ipr}\) is the time spent by repair person r on subsystem i under pattern p, and \(C_{ip}\) is the maintenance cost of pattern p for subsystem i. The binary decision variables \(x_{ip}\) represents the selection or not of pattern p for subsystem i.

Constraint (28b) guarantees that precisely one maintenance pattern is chosen for each subsystem. Ensuring that the total maintenance cost does not exceed the available maintenance budget is achieved through constraint (28c). Constraint (28d) stipulates that a repair person must be hired before they can perform work, and they cannot work beyond the break duration. The final constraint (28e), define the binary decision variable \(x_{ip}\) utilized in the formulation.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Al-Jabouri, H., Saif, A. & Diallo, C. Robust selective maintenance optimization of series–parallel mission-critical systems subject to maintenance quality uncertainty. Comput Manag Sci 20, 29 (2023). https://doi.org/10.1007/s10287-023-00464-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10287-023-00464-0