Abstract

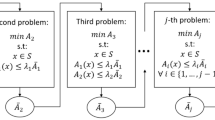

In this paper, we study the cyclic scheduling problem for electroplating lines where products are loaded into the system at one end and unloaded at the other end. The electroplating jobs must be processed within a given time window in each tank. There is no buffer between tanks. Two hoists sharing a common track are used to move products between the tanks in the production line. The objective is to minimize the production cycle time through scheduling hoist moves. A solution procedure is proposed in this study. The production line is first divided into two non-overlapping zones with a hoist assigned to each zone. Then a mixed integer linear programming model is developed for scheduling hoist moves. Computational results on a benchmark example problem are given in the paper to demonstrate the application of the proposed method.

Similar content being viewed by others

References

Anon (2004). CPLEX manual. Incline Village: CPLEX optimization. Inc.

Baptiste, P., Legeard, B., & Varnier, C. C. (1992). Hoist scheduling problem: an approach based on constraints logic programming. In Proc. IEEE int. conf. robotics and automation. Nice, France. 2, pp. 1139–1144.

Che, A., & Chu, C. (2004). Single- track multi-hoist scheduling problems: a collision-free resolution based on a branch-and-bound approach. International Journal of Production Research, 42(12).

Chen, H., Chu, C., & Proth, J. M. (1998). Cyclic scheduling of a hoist with time window constraints. IEEE Transaction Robot. Automation, 14, 144–152.

Kats, V., & Levner, E. (1997). Minimizing the number of robots to meet a given cyclic schedule. Annals of Operations Research, 69, 209–226.

Lei, L., & Wang, T. J. (1989). A proof: The cyclic hoist scheduling problem is NP-complete. Working Paper 89-0016. Rutgers Univ., New Brunswick, NJ.

Lei, L., & Wang, T. J. (1991). The minimum common-cycle algorithm for cyclic scheduling of two material handling hoists with time windows constraints. Management Science, 37, 1629–1639.

Lei, L. (1993). Determining the optimal starting times in a cyclic schedule with a given route. Computers & Operations Research, 20, 807–816.

Lei, L., & Wang, T. J. (1994). Determining optimal cyclic hoist schedules in a single-hoist electroplating line. IEEE Transaction, 26(2), 25–33.

Leung, J., & Zhang, G. (2003). Optimal cyclic scheduling for printed circuit board production lines with multiple hoists and general processing sequence. IEEE Transactions on Robotics and Automation, 9(3), 480–484.

Møller, C. (2007). Process innovation laboratory: a new approach to business process innovation based on enterprise information systems. Enterprise Information Systems, 1(1), 113–128.

Ng, W. C. (1996). A branch and bound algorithm for hoist scheduling of a circuit board production line. International Journal of Flexible Manufacturing Systems, 8, 45–65.

Olson, D. L., & Zhao, F. (2007). CIOs’ perspectives of critical success factors in ERP upgrade projects. Enterprise Information Systems, 1(1), 129–138.

Phillips, L. W., & Unger, P. S. (1976). Mathematical programming solution of a hoist scheduling program. AIIE Transaction, 8(2), 219–225.

Varnier, C. (1997). Resolution of the cyclic multi-hoists scheduling problem with overlapping partitions. INFORMS, 35(4), 309–324.

Shapiro, G. W., & Nuttle, H. L. W. (1988). Hoist scheduling for a KB electroplating facility. IIE Transaction, 20(2), 157–167.

Warfield, J. N. (2007). Systems science serves enterprise integration: a tutorial. Enterprise Information Systems, 1(2), 235–254.

Xu, L. (2007). Editorial. Enterprise Information Systems, 1(1), 1–2.

Zhou, Z., & Li, L. (2003). Single hoist cyclic scheduling with multi-tank: a material handling solution. Computers & Operations Research, 30, 811–819.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhou, Z., Li, L. A solution for cyclic scheduling of multi-hoists without overlapping. Ann Oper Res 168, 5–21 (2009). https://doi.org/10.1007/s10479-008-0372-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10479-008-0372-8