Abstract

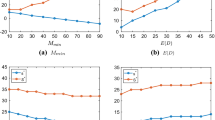

In this paper, we study an inventory system with multiple retailers under periodic review and stochastic demand. The demand is modelled as a discrete random variable. Linear holding and backorder costs as well as fixed order costs are assumed. Orders to replenish inventories can be placed at a manufacturer with a limited capacity according to a cyclic order schedule. A fixed portion of the total available capacity in a period is allocated to each retailer, who follows a modified base-stock policy to determine the order quantities. Thus, the order policy consists of four policy parameters for each retailer: the length of the review period, the first order point within a planning horizon, the individual capacity limit, and the modified base-stock level. We present an algorithm to compute the exact optimal policy parameters and two heuristics. In a numerical study, we compare the results of these approaches and derive insights into the performance of the heuristics. In addition, we introduce three different schedule types and identify the situations, in which they perform best.

Similar content being viewed by others

References

Axsäter, S. (2003). Supply chain operations: Serial and distribution inventory systems. In A. G. de Kok & S. C. Graves (Eds.), Supply chain management: Design, coordination and operation//Supply chain management, handbooks in operations research and management science (Vol. 11, pp. 525–559). Amsterdam: Elsevier.

Axsäter, S. (2007). On the first come-first served rule in multi-echelon inventory control. Naval Research Logistics (NRL) 54(5), 485–491. http://onlinelibrary.wiley.com/doi/10.1002/nav.20225/abstract.

Axsäter, S., & Marklund, J. (2008). Optimal position-based warehouse ordering in divergent two-echelon inventory systems. Operations Research, 56(4), 976–991.

Chan, G. H., & Song, Y. (2003). A dynamic analysis of the single-item periodic stochastic inventory system with order capacity. European Journal of Operational Research, 146, 529–542.

DeCroix, G. A., & Arreola-Risa, A. (1998). Optimal production and inventory policy under resource constraints. Management Science, 44(7), 950–961.

Diks, E. B., & de Kok, A. G. (1998). Optimal control of a divergent multi-echelon inventory system. European Journal of Operational Research, 111(1), 75–97.

Dogru, M. K., de Kok, A. G., & van Houtum, G. J. (2009). A numerical study on the effect of the balance assumption in one-warehouse multi-retailer inventory systems. Flexible Services an Manufacuring Journal, 21(3–4), 114–147.

Eppen, G. D., & Schrage, L. (1981). Centralized ordering policies in a multi-warehouse system with lead times and random demand. TIMS Studies in the Management Science, 16(1981), 51–67.

Evans, R. V. (1967). Inventory control of a multiproduct system with a limited production resource. Naval Research Logistics Quarterly, 14(14), 173–184.

Federgruen, A., & Zipkin, P. H. (1984). Allocation policies and cost approximations for multilocation inventory systems. Naval Research Logistics 31(1), 97–129. http://onlinelibrary.wiley.com/doi/10.1002/nav.3800310112/abstract;jsessionid=8C36592506D2B3C94E82BA237A3C7E9E.f03t03.

Federgruen, A., & Zipkin, P. H. (1984a). Approximations of dynamic, multilocation production and inventory problems. Management Science, 30(1), 69–84.

Federgruen, A., & Zipkin, P. H. (1986). An inventory model with limited production capacity and uncertain demands I: The average-cost criterion. Mathematics of Operations Research, 11(2), 193–207.

Gallego, G., & Scheller-Wolf, A. (2000). Capacitated inventory problems with fixed order costs: Some optimal policy structure. European Journal of Operational Research, 126, 603–613.

Glassermann, P. (1996). Allocating production capacity among multiple products. Operations Research, 44(5), 724–734.

Howard, C., & Marklund, J. (2011). Evaluation of stock allocation policies in a divergent inventory system with shipment consolidation. European Journal of Operational Research 211(2), 298–309. http://www.sciencedirect.com/science/article/pii/S0377221710008106.

Kiesmüller, G. P., & de Kok, A. G. (2005). A multi-item multi-echelon inventory system with quantity-based order consolidation. Beta, Research School for Operations Management and Logistics.

Kiesmüller, G. P., de Kok, A. G., & Dabia, S. (2011). Single item inventory control under periodic review and a minimum order quantity. International Journal of Production Economics, 133, 280–285.

Kleintje-Ell, F., & Kiesmüller, G. P. (2013). Simplified newsboy inequalities: Heuristics for the capacitated inventory problem. In Z. V. Sovresk, M. Mokrys, S. Badura, & A. Lieskovsky (Eds.), Proceedings in Global Virtual Conference (Vol. 1, pp. 618–623). Zilina: EDIS Publishing Institution of the University of Zilina.

Scarf, H. E. (1963). Analytic techniques in inventory theory, office of naval research monographs on mathematical methods in logistics, (1st ed., Vol. 1). Stanford: Stanford University Press.

Shaoxiang, C., & Lambrecht, M. (1996). X–Y band and modified (s, S) policy. Operations Research, 44(6), 1013–1019.

Simichi-Levi, D., & Zhao, Y. (2012). Performance evaluation of stochastic multi-echelon inventory systems: A survey. Advances in Operations Research, 2012, 1–34.

Zhao, Y., & Katehakis. M. N. (2006). On the structure of optimal ordering policies for stochastic inventory systems with minimum order quantity. Probability in the Engineering and Informational Sciences 20(02), 257–270. http://journals.cambridge.org/article_S0269964806060165.

Zhou, B., Katehakis, M. N., & Zhao, Y. (2009). Managing stochastic inventory systems with free shipping option. European Journal of Operational Research 196(1), 186–197. http://www.sciencedirect.com/science/article/pii/S0377221708001768.

Author information

Authors and Affiliations

Corresponding author

Appendices

Appendix I: Derivation of the cost functions

1.1 The exact cost function

In order to be able to compute the average stock on hand or backorders, we need information about the distribution of the inventory position, which can be obtained using a Markov chain approach. The state space of the Markov chain is given by the undershoot \(U_t\), which is defined as the difference between the modified base-stock level \(S_m\) and the inventory position \(IP_m\) at the beginning of a period \(t\) after an order has been placed. The dynamic of the system is described by the following recursive equation for the undershoot:

The equilibrium distribution \(\pi \) defined as

can be computed by solving the system of equations

where \(P\) denotes the transition matrix given as

With Eq. (2), this results in the following expression for the average holding and backorder cost:

For the given values of \(CP_m, R_m\), the cost function depends on the modified base-stock level \(S_m\) only. The optimal modified base-stock level \(S^*_m\) then has to satisfy the following Newsboy like condition:

1.2 The approximated cost function

During the optimisation, many combinations of policy parameters have to be evaluated. Since for each \((R_m,CP_m)\) combination a system of equations has to be solved to determine \(S_m\), this may result in long computation times. Therefore, in some parts of the heuristic approaches, we use an approximated cost function where the Eq. (21) for the undershoot is replaced by

and the convolution of the resulting probability mass function with the probability mass function for the period demand is replaced by a two-moment fit of these. Both assumptions correspond to those found in Kleintje-Ell and Kiesmüller (2013). With the fitted probability mass function \(f_{fit}\), the cost function results in:

Appendix II Upper bound for \(R_m\)

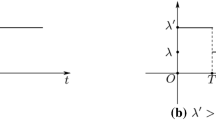

In the following section, we show why \((E[D_i]+1)\cdot R_m\) is the lowest capacity for the other retailers that needs to be taken into account of all schedules \(X\) with any length \(T\) containing the order interval \(R_m\) for retailer \(m\). The following distinction of cases for the possible order intervals of the retailers \(i \ne m\) demonstrates this:

- \(R_i < R_m\) :

-

We determine the highest possible number of orders of retailer \(i\) for an interval \(R_m: count:= \max _{\bar{t}<T} \sum ^{\bar{t}+R_m}_{t=\bar{t}} x_{i,t}\). In this case, it holds that: \(R_m \cdot (E[D_i]+1)\le count \cdot R_i \cdot (E[D_i]+1) \) as \(count \ge \frac{R_m}{R_i}\).

- \(R_i = R_m\) :

-

We assume the correct minimum capacity with \((E[D_i]+1)\cdot R_m\).

- \(R_m<R_i \) :

-

If there exists an order interval of length \(R_m\), in which both retailer \(m\) and retailer \(i\) place an order, the capacity limit of a retailer is the same at each of his orders. In this case, it holds that \(R_m \cdot (E[D_i]+1) < R_i \cdot (E[D_i]+1)\) and we even underestimate the amount required by retailer \(i\).

- \(R_i,R_j \ge 2 \cdot R_m\; , \; R_i = R_j\) :

-

There may be certain combinations of order intervals in these cases, such that the three retailers \(m,i,j\) never order all together in an interval of length \(R_m\), but rather in intervals in which \(i\) orders, the distance to the order points of \(m\) are the same as for \(j\) in the corresponding intervals. If we assume w.l.o.g. \(E[D_i]\le E[D_j]\), it holds that \((E[D_i]+1)\cdot R_m + (E[D_j]+1)\cdot R_m \le (E[D_j]+1)\cdot 2 \cdot R_m \le (E[D_j]+1)\cdot R_j\) and in these cases as well, the assumed capacity does not overestimate the amount needed by other retailers in an interval of length \(R_m\).

Rights and permissions

About this article

Cite this article

Kleintje-Ell, F., Kiesmüller, G.P. Cost minimising order schedules for a capacitated inventory system. Ann Oper Res 229, 501–520 (2015). https://doi.org/10.1007/s10479-015-1812-x

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10479-015-1812-x