Abstract

In this paper, two new joint maintenance and spare parts provisioning policies for a multi-unit production system are proposed. The production system consists of N identical, independent units, each subject to gradual deterioration. Production rates of the units depend on their operating states. Every maintenance action incurs a high set-up cost which includes the cost of sending a crew to the field, and it is therefore cost effective to maintain several units at the same time. The paper’s main contribution is an analytical modeling of a multi-unit production system and the development of effective joint maintenance and spare parts ordering policies for such system. The states of the units are observable through regular inspections and the maintenance and spare part ordering decisions depend on the number of the failed units and the number of available spare parts. The process is formulated as a semi-Markov decision process with the optimality criterion being the minimization of the total long-run expected average cost per unit time. The objective is to determine the optimal levels of the number of failed units to place an order for the spare parts or to initiate group maintenance, and to find the optimal inspection interval. Numerical examples are provided to illustrate the proposed optimization model and to compare the two maintenance policies. Sensitivity analysis is conducted to analyze the effect of several cost components on the optimal levels and on the long run expected average cost rate.

Similar content being viewed by others

References

Ahmadi, R. (2014). Optimal maintenance scheduling for a complex manufacturing system subject to deterioration. Annals of Operations Research, 217(1), 1–29.

Asadi, M., & Bayramoglu, I. (2006). The mean residual life function of a k-out-of-n structure at the system level. IEEE Transactions on Reliability, 55(2), 314–318.

Barron, Y. (2015). Group replacement policies for a repairable cold standby system with fixed lead times. IIE Transactions, 47(10), 1139–1151.

Barron, Y. (2018). Group maintenance policies for an R-out-of-N system with phase-type distribution. Annals of Operations Research, 261(1–2), 79–105.

Barron, Y., Frostig, E., & Levikson, B. (2004). Analysis of r-out-of-n repairable systems: The case of phase-type distributions. Advances in Applied Probability, 36(1), 116–138.

Barron, Y., & Yechiali, U. (2017). Generalized control-limit preventive repair policies for deteriorating cold and warm standby markovian systems. IISE Transactions, 49(11), 1031–1049.

Bevilacqua, M., & Braglia, M. (2000). The analytic hierarchy process applied to maintenance strategy selection. Reliability Engineering & System Safety, 70(1), 71–83.

Bohlin, M., & Wärja, M. (2015). Maintenance optimization with duration-dependent costs. Annals of Operations Research, 224(1), 1–23.

Byon, E., & Ding, Y. (2010). Season-dependent condition-based maintenance for a wind turbine using a partially observed markov decision process. IEEE Transactions on Power Systems, 25(4), 1823–1834.

de Smidt-Destombes, K. S., van der Heijden, M. C., & van Harten, A. (2004). On the availability of a k-out-of-n system given limited spares and repair capacity under a condition based maintenance strategy. Reliability Engineering & System Safety, 83(3), 287–300.

de Smidt-Destombes, K. S., van der Heijden, M. C., & Van Harten, A. (2006). On the interaction between maintenance, spare part inventories and repair capacity for a k-out-of-n system with wear-out. European Journal of Operational Research, 174(1), 182–200.

Debnath, L., & Bhatta, D. (2014). Integral transforms and their applications. Boca Raton: CRC Press.

Dieulle, L., Bérenguer, C., Grall, A., & Roussignol, M. (2003). Sequential condition-based maintenance scheduling for a deteriorating system. European Journal of operational research, 150(2), 451–461.

EIA (2019). Average price of electricity to ultimate customers by end-use sector. https://www.eia.gov.

El Moudani, W., & Mora-Camino, F. (2000). A dynamic approach for aircraft assignment and maintenance scheduling by airlines. Journal of Air Transport Management, 6(4), 233–237.

Eruguz, A. S., Tan, T., & van Houtum, G. J. (2017). Optimizing usage and maintenance decisions for k-out-of-n systems of moving assets. Naval Research Logistics (NRL), 64(5), 418–434.

Eryilmaz, S., & Xie, M. (2014). Dynamic modeling of general three-state k-out-of-n: G systems: Permanent-based computational results. Journal of Computational and Applied Mathematics, 272, 97–106.

Jafari, L., Naderkhani, F., & Makis, V. (2018). Joint optimization of maintenance policy and inspection interval for a multi-unit series system using proportional hazards model. Journal of the Operational Research Society, 69(1), 36–48.

Jardine, A. K., Lin, D., & Banjevic, D. (2006). A review on machinery diagnostics and prognostics implementing condition-based maintenance. Mechanical systems and signal processing, 20(7), 1483–1510.

Jia, X., Shen, J., & Xing, R. (2016). Reliability analysis for repairable multistate two-unit series systems when repair time can be neglected. IEEE Transactions on Reliability, 65(1), 208–216.

Jiang, R., Kim, M. J., & Makis, V. (2012). A bayesian model and numerical algorithm for cbm availability maximization. Annals of Operations Research, 196(1), 333–348.

Keizer, M. C. O., Teunter, R. H., & Veldman, J. (2017). Joint condition-based maintenance and inventory optimization for systems with multiple components. European Journal of Operational Research, 257(1), 209–222.

Keizer, M. C. O., Teunter, R. H., Veldman, J., & Babai, M. Z. (2018). Condition-based maintenance for systems with economic dependence and load sharing. International Journal of Production Economics, 195, 319–327.

Kennedy, W., Patterson, J. W., & Fredendall, L. D. (2002). An overview of recent literature on spare parts inventories. International Journal of production economics, 76(2), 201–215.

Khaleghei, A., & Makis, V. (2015). Model parameter estimation and residual life prediction for a partially observable failing system. Naval Research Logistics (NRL), 62(3), 190–205.

Khaleghei, A., & Makis, V. (2016). Reliability estimation of a system subject to condition monitoring with two dependent failure modes. IIE Transactions, 48(11), 1058–1071.

Kontoleon, J., & Kontoleon, N. (1974). Reliability analysis of a system subject to partial and catastrophic failures. IEEE Transactions on Reliability, 23(4), 277–278.

Lanza, G., Niggeschmidt, S., & Werner, P. (2009). Optimization of preventive maintenance and spare part provision for machine tools based on variable operational conditions. CIRP Annals-Manufacturing Technology, 58(1), 429–432.

Maggard, B. N., & Rhyne, D. M. (1992). Total productive maintenance: A timely integration of production and maintenance. Production and Inventory Management Journal, 33(4), 6.

Moghaddam, K. S., & Usher, J. S. (2011). Preventive maintenance and replacement scheduling for repairable and maintainable systems using dynamic programming. Computers & Industrial Engineering, 60(4), 654–665.

Nicolai, R. P., & Dekker, R. (2008). Optimal maintenance of multi-component systems: A review. In Complex system maintenance handbook (pp. 263–286). London: Springer.

Niu, C., Liang, X., Ge, B., Tian, X., & Chen, Y. (2016). Optimal replacement policy for a repairable system with deterioration based on a renewal-geometric process. Annals of Operations Research, 244(1), 49–66.

Rahmati, S. H. A., Ahmadi, A., & Govindan, K. (2018). A novel integrated condition-based maintenance and stochastic flexible job shop scheduling problem: Simulation-based optimization approach. Annals of Operations Research, 269(1–2), 583–621.

Rao, A. N., & Bhadury, B. (2000). Opportunistic maintenance of multi-equipment system: A case study. Quality and Reliability Engineering International, 16(6), 487–500.

Salari, N., & Makis, V. (2017a). Comparison of two maintenance policies for a multi-unit system considering production and demand rates. International Journal of Production Economics, 193, 381–391.

Salari, N., & Makis, V. (2017b). Optimal preventive and opportunistic maintenance policy for a two-unit system. The International Journal of Advanced Manufacturing Technology, 89(1–4), 665–673.

Tian, Z., Jin, T., Wu, B., & Ding, F. (2011). Condition based maintenance optimization for wind power generation systems under continuous monitoring. Renewable Energy, 36(5), 1502–1509.

Tijms, H. C. (1986). Stochastic modelling and analysis: A computational approach. Hoboken: Wiley.

Wang, H., & Pham, H. (1999). Some maintenance models and availability withimperfect maintenance in production systems. Annals of Operations Research, 91, 305–318.

Wang, L., Chu, J., & Mao, W. (2009). A condition-based replacement and spare provisioning policy for deteriorating systems with uncertain deterioration to failure. European Journal of Operational Research, 194(1), 184–205.

Wang, W. (2011). A joint spare part and maintenance inspection optimisation model using the delay-time concept. Reliability Engineering & System Safety, 96(11), 1535–1541.

Wang, W. B. (2000). A model to determine the optimal critical level and the monitoring intervals in condition-based maintenance. International Journal of Production Research, 38(6), 1425–1436.

Yeh, R. H., Chang, W. L., & Lo, H. C. (2010). Optimal threshold values of age and two-phase maintenance policy for leased equipments using age reduction method. Annals of Operations Research, 181(1), 171–183.

Zhou, X., Xi, L., & Lee, J. (2009). Opportunistic preventive maintenance scheduling for a multi-unit series system based on dynamic programming. International Journal of Production Economics, 118(2), 361–366.

Acknowledgements

The authors would like to thank the Natural Sciences and Engineering Research Council of Canada for the financial support under Grant No. RGPIN 121384-11, and the two anonymous referees for their constructive comments.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix A: Calculation of transition probabilities for each unit

The instantaneous deterioration transition rates \(q_{ij}\), \(i,j\in {\varOmega }\) for each unit are defined by:

where \(i,\ j\ \in \{0,1,F\}\), and the state transition matrix P(t) can be written as follows:

where the exponential distribution parameters of the sojourn times are denoted by \(\nu _0=q_{01}+q_{0F}\) and \(\nu _1=q_{1F}\).

We assume that the state process is non-decreasing with probability 1, i.e., \(q_{ij}=0\) for all \(j<i\) and failure state is absorbing. The Kolmogorov’s backward differential equations for given transition rates can be written as follows:

Extensive details on the Laplace transform can be found in Debnath and Bhatta (2014). Taking Laplace transform of the above equations, the following equations are obtained:

where \({\overline{P}}_{ij}(s)\) is the Laplace transform of the transition probability \(P_{ij}(t)\), which is written as: \({\overline{P}}_{ij}(s)=\int _{0}^{\infty } e^{-st} P_{ij}(t)dt\). By solving the above equations we get:

By taking the inverse Laplace transform of the above equations, we derive the transition probabilities as follows:

Appendix B: Proof of Theorem 5

Assume that the state of the system is \((n_F,n_1,S)\) and the decision is to perform maintenance. If the state of the system changes to \((n_F+i,n_1',S), \ i\ge 0\) during \(T_R\) (or \(T_P\)) an emergency order of size \(n_F+i-S\) is placed. The expected cost of emergency ordering in state \((n_F,n_1,S)\) for different values of i is as follows:

where \(x=0\), for \(n_1' \ge n_1\), and \(x=n_1-n_1'\), for \(n_1'<n_1\).

For the first maintenance policy, the expected cost of corrective replacement in state \((n_F,n_1,S)\) is equal to:

where \(x=0\) for \(n_1' \ge n_1\), and \(x=n_1-n_1'\) for \(n_1'<n_1\).

The expected cost of corrective replacement and preventive maintenance for the second policy in state \((n_F,n_1,S)\) is equal to:

where \(x=0\) for \(n_1' \ge n_1\), and \(x=n_1-n_1'\) for \(n_1'<n_1\).

Appendix C: Extension to more than 3 state deterioration process

First, we will show how to extend the model to a more complex case of a 4 state deterioration process (we consider 4 states for each unit of the system). This change affects the number of system states, transition probabilities, production rate and the expected cost. In this section we provide the formula to calculate the transition probabilities. The calculation of the expected cost is similar to to the previous case (3 state deterioration process).

Consider a system consisting of N units where deterioration process of each unit is modeled as a 4-state continuous time homogeneous Markov chain with three working states and a failure state F which is absorbing, \(\varOmega =\{0,1,2,F\}\). The state space for the whole system can be defined as \(W =\{(n_F,n_2,n_1, S)\mid n_1+n_2+n_F\le N, n_1, n_2, n_F, S\ge 0\}\), where \(n_F\) , \(n_2\), and \(n_1\) represent the number of units in the failure state, state 2, and state 1, respectively, and S represents the on-hand inventory. Based on Remark 2, the number of available spare parts in the system at each inspection time can be 0 or R, so the number of states for this system is equal to \(\frac{(N+1)(N+2)(N+3)\times 2}{3!}\).

The transition probability function when the decision is to continue operation is as follows:

Figure 3 shows the number of units which change their state in the next time interval of length \(\varDelta \) when deterioration process of units has 4 states.

The transition probability when the decision is to perform maintenance is given by the following formulas:

For the first maintenance policy,

$$\begin{aligned}&P_{(n_F,n_2,n_1,S)(0,n_2',n_1', 0)}(T_R)= \nonumber \\&\sum _{i=max\{0, n_1+n_2-n_1'-n_2'\}}^{N-n_F-n_1'-n_2'}\sum _{k=max\{0,n_2-n_2'\}}^{min\{i,n_2\}} \sum _{j=max\{0,i-k-n_0\}}^{min\{i-k,n_1\}}\sum _{m=max\{0,n_1-n_1'-j\}}^{min\{n_1-j,n_2'-n_2+k\}} \left( {\begin{array}{c}n_0\\ i-j-k\end{array}}\right) \nonumber \\&\left( {\begin{array}{c}n_0-i+k+j\\ n_1'-n_1+m+j\end{array}}\right) \left( {\begin{array}{c}n_0-i+k-n_1'+n_1-m\\ n_2'-n_2+k-m\end{array}}\right) \left( {\begin{array}{c}n_1\\ j\end{array}}\right) \left( {\begin{array}{c}n_1-j\\ m\end{array}}\right) \left( {\begin{array}{c}n_2\\ k\end{array}}\right) \nonumber \\&\left( \int _0^\infty P_{00}(u)^{n_0'}P_{01}(u)^{n_1'-n_1+j+m} P_{02}(u)^{n_2'-n_2+k-m} P_{0F}(u)^{i-j-k} P_{11}(u)^{n_1-m-j}\right. \nonumber \\&\left. P_{12}(u)^{m} P_{1F}(u)^{j} P_{22}(u)^{n_2-k}P_{2F}(u)^{k} \times f_{T_R} (u) du\right) \end{aligned}$$(18)For the second maintenance policy,

$$\begin{aligned} P_{(n_F,n_2,n_1,S)(0,0,0, 0)}(T_P)=1 \end{aligned}$$

As can be seen, the number of system states increases dramatically and the calculation of transition probability becomes quite complicated by adding new states. We assume that a transition to a different state may or may not occur during the next \(\varDelta \) time units, which makes it difficult to calculate transition probabilities for the system. Some simplification is possible for reliable systems, for which transitions to some states can be eliminated. So, we can consider a system consisting of N units where deterioration process of each unit is modeled as an m-state continuous time homogeneous Markov chain with \(m-1\) working states and a failure state F which is absorbing, \(\varOmega =\{0,1,2,\ldots ,m-1,F\}\). The multi-state structure is considered where transitions are allowed either to the neighbor state or to the failure state. For highly reliable systems, we can omit any intermediate transition between states during each inspection interval (see Fig. 4).

The state space for the whole system can be defined as \(W =\{(n_F,n_{m-1},\ldots ,n_1, S)\mid n_1+\cdots +n_F\le N, n_1,\ldots , n_F, S\ge 0\}\), where \(n_F\) , \(n_i\ i\in \{0,1,\ldots ,m-1\}\) represent the number of units in the failure state, and state i, respectively, and S represents the on-hand inventory.

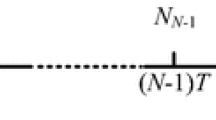

The transition probability function when the decision is to continue operation is given by:

where

Rights and permissions

About this article

Cite this article

Salari, N., Makis, V. Joint maintenance and just-in-time spare parts provisioning policy for a multi-unit production system. Ann Oper Res 287, 351–377 (2020). https://doi.org/10.1007/s10479-019-03371-3

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10479-019-03371-3