Abstract

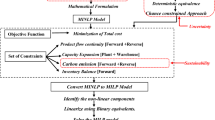

The paper addresses the problem of designing a multi-country production–distribution network that also provides services such as repairs and remanufacturing. The proposed work concentrates primarily on post-sale service provided by the firm under warranty returns. The proposed model assumes that existing warehouses can also serve as collection centres or repair centres for reverse logistics. In addition, the model also explores the possibility of establishing a new facility. Hybrid facilities are considered because of their huge cost-cutting potential due to equipment sharing and space sharing. The capacity of hybrid facilities can be expanded to a predefined limit to process returned products without hampering forward logistics operations. However, if a product cannot be repaired at the warehouse, it is transported to the plant for remanufacturing. The model optimizes the overall configuration and operation cost of the production–distribution network. The production–distribution model developed in the paper is a mixed-integer nonlinear program (MINLP) that is later transformed to a mixed-integer linear program to reduce the solution time. The usefulness of the model is illustrated using a randomly generated dataset. The model identifies (a) the optimal locations/allocations of the existing/new facilities, (b) the distribution of returned products for refurbishing and remanufacturing, and (c) the capacity expansion of the existing plants and warehouses to facilitate remanufacturing and repair services.

Similar content being viewed by others

References

Abdallah, T., Diabat, A., & Simchi-Levi, D. (2012). Sustainable supply chain design: A closed-loop formulation and sensitivity analysis. Production Planning & Control, 23(2–3), 120–133.

Aldrighetti, R., Zennaro, I., Finco, S., & Battini, D. (2019). Healthcare supply chain simulation with disruption considerations: A case study from Northern Italy. Global Journal of Flexible Systems Management, 20(1), 81–102.

Allied Market Research. (2019). Reverse logistics market to reach 603.9 billion dollars, globally by 2025 at 4.6% CAGR. Retrieved March 24, 2020, from https://www.prnewswire.com/news-releases/reverse-logistics-market-to-reach-603-9-bn-globally-by-2025-at-4-6-cagr-amr-300817572.html.

Amin, S. H., & Baki, F. (2017). A facility location model for global closed-loop supply chain network design. Applied Mathematical Modelling, 41, 316–330.

Bhatnagar, R., & Viswanathan, S. (2000). Re-engineering global supply chains: Alliances between manufacturing firms and global logistics services providers. International Journal of Physical Distribution & Logistics Management, 30(1), 13–34.

Business Strategy Report. (2015). The unexpected benefits of product returns. Retrieved March 24, 2020, from https://www.strategy-business.com/blog/The-Unexpected-Benefits-of-Product-Returns?gko=b808b.

Chen, Y. W., Wang, L. C., Wang, A., & Chen, T. L. (2017). A particle swarm approach for optimizing a multi-stage closed loop supply chain for the solar cell industry. Robotics and Computer-Integrated Manufacturing, 43, 111–123.

Cognizant 2020 Insights. (2011). Reverse supply chain: Completing the supply chain loop. Retrieved March 24, 2020, from https://www.cognizant.com/whitepapers/reverse-supply-chain.pdf.

Cohen, M. A., & Lee, H. L. (1988). Strategic analysis of integrated production-distribution systems: Models and methods. Operations Research, 36(2), 216–228.

Creazza, A., Dallari, F., & Melacini, M. (2010). Evaluating logistics network configurations for a global supply chain. Supply Chain Management: An International Journal, 15(2), 154–164.

Dolgui, A., Ivanov, D., & Sokolov, B. (2020). Reconfigurable supply chain: The X-network. International Journal of Production Research, 58(13), 4138–4163.

Dong, L., Kouvelis, P., & Su, P. (2013). Global facility network design in the presence of competition. European Journal of Operational Research, 228(2), 437–446.

Du, F., & Evans, G. W. (2008). A bi-objective reverse logistics network analysis for post-sale service. Computers & Operations Research, 35(8), 2617–2634.

Erica, P. E. (2018). What stores do with $90 billion in merchandise returns? The Wall Street Journal. Logistics report Feb, 2018. https://www.wsj.com/articles/what-stores-do-with-90-billion-in-merchandise-returns-1518777000?ns=prod/accounts-wsj.

Fleischmann, M. (2001). Quantitative models for reverse logistics (Vol. 501)., Lecture notes in economics and mathematical systems Berlin: Springer.

Ganji, E. N., Shah, S., & Coutroubis, A. (2017). Sustainable supply and demand chain integration within global manufacturing industries. In 2017 IEEE international conference on industrial engineering and engineering management (IEEM) (pp. 1807–1811). IEEE.

Gianesello, P., Ivanov, D., & Battini, D. (2017). Closed-loop supply chain simulation with disruption considerations: A case-study on Tesla. International Journal of Inventory Research, 4(4), 257–280.

Hosseini, S., Morshedlou, N., Ivanov, D., Sarder, M. D., Barker, K., & Al Khaled, A. (2019). Resilient supplier selection and optimal order allocation under disruption risks. International Journal of Production Economics, 213, 124–137.

Ivanov, D. (2010). An adaptive framework for aligning (re) planning decisions on supply chain strategy, design, tactics, and operations. International Journal of Production Research, 48(13), 3999–4017.

Ivanov, D. (2020a). Predicting the impacts of epidemic outbreaks on global supply chains: A simulation-based analysis on the coronavirus outbreak (COVID-19/SARS-CoV-2) case. Transportation Research Part E: Logistics and Transportation Review, 136, 101922.

Ivanov, D. (2020b). Viable supply chain model: integrating agility, resilience and sustainability perspectives—Lessons from and thinking beyond the COVID-19 pandemic. Annals of Operations Research. https://doi.org/10.1007/s10479-020-03640-6.

Ivanov, D., Das, A., & Choi, T. M. (2018). New flexibility drivers for manufacturing, service, and supply chain systems. International Journal of Production Research, 56(10), 3359–3368.

Ivanov, D., & Dolgui, A. (2020). Viability of intertwined supply networks: Extending the supply chain resilience angles towards survivability. A position paper motivated by COVID-19 outbreak. International Journal of Production Research, 58(10), 2904–2915.

Ivanov, D., Pavlov, A., & Sokolov, B. (2014). Optimal distribution (re) planning in a centralized multi-stage supply network under conditions of the ripple effect and structure dynamics. European Journal of Operational Research, 237(2), 758–770.

Ivanov, D. A., Sokolov, B. V., & Kaeschel, J. (2009). Structure dynamics control-based framework for adaptive reconfiguration of collaborative enterprise networks. International Journal of Manufacturing Technology and Management, 17(1–2), 23–41.

Ivanov, D., Sokolov, B., & Kaeschel, J. (2010). Integrated supply chain planning based on a combined application of operations research and optimal control. Central European Journal of Operations Research, 19(3), 299–317.

Ivanov, D., Sokolov, B., & Pavlov, A. (2013). Dual problem formulation and its application to optimal redesign of an integrated production–distribution network with structure dynamics and ripple effect considerations. International Journal of Production Research, 51(18), 5386–5403.

Ivanov, D., Tsipoulanidis, A., & Schönberger, J. (2017). Global supply chain and operations management. A decision-oriented introduction to the creation of value. Berlin: Springer.

Jerbia, R., Boujelben, M. K., Sehli, M. A., & Jemai, Z. (2018). A stochastic closed-loop supply chain network design problem with multiple recovery options. Computers & Industrial Engineering, 118, 23–32.

John, S. T., Sridharan, R., & Kumar, P. R. (2017). Multi-period reverse logistics network design with emission cost. The International Journal of Logistics Management, 28(1), 127–149.

John, S. T., Sridharan, R., Kumar, P. R., & Krishnamoorthy, M. (2018). Multi-period reverse logistics network design for used refrigerators. Applied Mathematical Modelling, 54, 311–331.

Kannan, D., Garg, K., Jha, P. C., & Diabat, A. (2016). Integrating disassembly line balancing in the planning of a reverse logistics network from the perspective of a third party provider. Annals of Operations Research, 253(1), 353–376.

Kaya, O., Bagci, F., & Turkay, M. (2014). Planning of capacity, production and inventory decisions in a generic reverse supply chain under uncertain demand and returns. International Journal of Production Research, 52(1), 270–282.

Kouvelis, P., Rosenblatt, M. J., & Munson, C. L. (2004). A mathematical programming model for global plant location problems: Analysis and insights. IIE Transactions, 36(2), 127–144.

Liao, T. Y. (2018). Reverse logistics network design for product recovery and remanufacturing. Applied Mathematical Modelling, 60, 145–163.

Melo, M. T., Nickel, S., & Da Gama, F. S. (2006). Dynamic multi-commodity capacitated facility location: A mathematical modeling framework for strategic supply chain planning. Computers & Operations Research, 33(1), 181–208.

Min, H., & Ko, H. J. (2008). The dynamic design of a reverse logistics network from the perspective of third-party logistics service providers. International Journal of Production Economics, 113(1), 176–192.

Mishra, S., & Singh, S. P. (2019). An environmentally sustainable manufacturing network model under an international ecosystem. Clean Technologies and Environmental Policy, 21(6), 1237–1257.

Mishra, S., & Singh, S. P. (2020a). Distribution network model using big data in an international environment. Science of the Total Environment, 707, 135549.

Mishra, S., & Singh, S. P. (2020b). A stochastic disaster-resilient and sustainable reverse logistics model in big data environment. Annals of Operations Research. https://doi.org/10.1007/s10479-020-03573-0.

Mishra, S., Singh, S. P., Johansen, J., Cheng, Y., & Farooq, S. (2019). Evaluating indicators for international manufacturing network under circular economy. Management Decision, 57(4), 811–839.

Nnorom, I. C., & Osibanjo, O. (2008). Overview of electronic waste (e-waste) management practices and legislations, and their poor applications in the developing countries. Resources, Conservation and Recycling, 52(6), 843–858.

Ozceylan, E., Demirel, N., Çetinkaya, C., & Demirel, E. (2017). A closed-loop supply chain network design for automotive industry in Turkey. Computers & Industrial Engineering, 113, 727–745.

Pishvaee, M. S., Jolai, F., & Razmi, J. (2009). A stochastic optimization model for integrated forward/reverse logistics network design. Journal of Manufacturing Systems, 28(4), 107–114.

Reddy, K. N., Kumar, A., & Ballantyne, E. E. (2018). A three-phase heuristic approach for reverse logistics network design incorporating carbon footprint. International Journal of Production Research, 57(19), 6090–6114.

Shekarian, M., Nooraie, S. V. R., & Parast, M. M. (2020). An examination of the impact of flexibility and agility on mitigating supply chain disruptions. International Journal of Production Economics, 220, 107438.

Srinivasan, S., & Khan, S. H. (2018). Multi-stage manufacturing/re-manufacturing facility location and allocation model under uncertain demand and return. The International Journal of Advanced Manufacturing Technology, 94(5–8), 2847–2860.

Tan, W. J., Cai, W., & Zhang, A. N. (2019). Structural-aware simulation analysis of supply chain resilience. International Journal of Production Research. https://doi.org/10.1080/00207543.2019.1705421.

Zhen, L., Sun, Q., Wang, K., & Zhang, X. (2019). Facility location and scale optimisation in closed-loop supply chain. International Journal of Production Research, 57(24), 7567–7585.

Acknowledgements

The authors would like to thank the Department of Science and Technology, Ministry of Science and Technology, New Delhi, India (IF170044), and University Grant Commission India-UKIERI (RP03411) for funding this research.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

Rights and permissions

About this article

Cite this article

Mishra, S., Singh, S.P. Designing dynamic reverse logistics network for post-sale service. Ann Oper Res 310, 89–118 (2022). https://doi.org/10.1007/s10479-020-03710-9

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10479-020-03710-9