Abstract

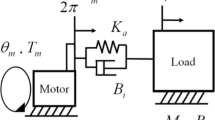

For mass resonant system, a long-term operation causes the system degrading which ends up with system vibration and affects system control accuracy. A number of model-based feedforward control methods were developed to compensate for such systematic control error. However, the parameters of the complex and nonlinear control systems need to be identified during the degrading process so that the precise speed control can be achieved as well as the health condition of the mechanical system can be extracted. This study proposes an equipment health maintenance framework in a three-mass resonant servo control system with the LuGre friction model, which conducts model-based parameter estimation and feedforward compensation. Since the traditional methods require off-line frequency-sweep which causes the downtime in the production line, we suggest a constrained particle swarm optimization (CPSO) to estimate the mechanical parameters so that the machine can operate simultaneously. More specifically, with embedding the soft equality constraints of the anti-resonance frequency in the mass resonant system, the CPSO enables the feasible region shrank and the vibration suppressed. In particular, we address these constraints by obtaining the feasibility-preserving approach with the dynamic relaxing constraints. An experimental study of a leading electronics manufacturing company in Taiwan has been conducted to validate the proposed approach with a designed experiment of a belt drive system. The results show that the mass resonant system with the LuGre friction model via CPSO successfully reflects the main effects of current variation in the mechanical system.

Similar content being viewed by others

References

Al-Bender, F. (2010) “Fundamentals of friction modeling,” in Proceedings, ASPE Spring Topical Meeting on Control of Precision Systems, MIT. pp. 117–122.

Amontons, G. (1699) “On the resistance originating in machines,” in Proc. French R. Acad. Sci., pp. 206–222.

Barbosa, H. J. C., Lemonge, A. C. C., & Bernardino, H. S. (2015). A critical review of adaptive penalty techniques in evolutionary computation. In R. Datta & K. Deb (Eds.), Evolutionary Constrained Optimization Infosys Science Foundation Series (pp. 1–27). Springer.

Cao, M., Wang, K. W., Fujii, Y., & Tobler, W. E. (2004). A hybrid neural network approach for the development of friction component dynamic model. Journal of Dynamic Systems, Measurement and Control, 126(1), 144–153.

Clerc, M. (2006) “Stagnation Analysis in Particle Swarm Optimisation or What Happens When Nothing Happens Reminder of classical PSO,” Tech. Rep. CSM-460.

de Coulomb, C. A. (1785), “Troisieme mémoire sur l’Électricité et le Magnétisme,” Hist. l’Académie R. des Sci., pp. 612–638.

Dahl, P. R. (1968) “A solid friction model,” Aerospace Corp El Segundo Ca.

De Wit, C. C., Olsson, H., Astrom, K. J., & Lischinsky, P. (1995). A new model for control of systems with friction. IEEE Transaction on Automatic Control, 40(3), 419–425.

Deb, K. (2000). An efficient constraint handling method for genetic algorithms. Computer Methods in Applied Mechanics and Engineering, 186(2–4), 311–338.

Hamamoto, K., Fukuda, T., & Sugie, T. (2003). Iterative feedback tuning of controllers for a two-mass-spring system with friction. Control Engineering Practice, 11(9), 1061–1068.

Hong, S. W., & Lee, C. W. (1991). Identification of linearised joint structural parameters by combined use of measured and computed frequency responses. Mechanical Systems and Signal Processing, 5(4), 267–277.

Hu, L., Wang, Z., Rahman, I., & Liu, X. (2016). A constrained optimization approach to dynamic state estimation for power systems including PMU and missing measurements. IEEE Transactions on Control Systems Technology, 24(2), 703–710.

Huang, R., Xi, L., Li, X., Liu, C. R., Qiu, H., & Lee, J. (2007). Residual life predictions for ball bearings based on self-organizing map and back propagation neural network methods. Mechanical Systems and Signal Processing, 21(1), 193–207.

Iwasaki, M., Miwa, M., & Matsui, N. (2005). GA-based evolutionary identification algorithm for unknown structured mechatronic systems. IEEE Transactions on Industrial Electronics, 52(1), 300–305.

Jiang, M., Huang, Z., Qiu, L., Huang, W., & Yen, G. G. (2017). Transfer learning-based dynamic multiobjective optimization algorithms. IEEE Transactions on Evolutionary Computation, 22(4), 501–514.

Kennedy, J., Eberhart, R. (1995) Particle swarm optimization (PSO), in Proc. Int. Conf. Neural Networks, Perth, Australia, pp. 1942–1948.

Kharoufeh, J. P., Cox, S. M., & Oxley, M. E. (2013). Reliability of manufacturing equipment in complex environments. Annals of Operations Research, 209, 231–254.

Kshirsagar, P., Jiang, D., & Zhang, Z. (2016). Implementation and evaluation of online system identification of electromechanical systems using adaptive filters. IEEE Transactions on Industry Applications, 52(3), 2306–2314.

Lee, C.-Y., Chien, C.-F. (2020) Pitfalls and protocols of data science in manufacturing practice. Journal of Intelligent Manufacturing. https://doi.org/10.1007/s10845-020-01711-w

Lee, C.-Y., Huang, T.-S., Liu, M.-K., & Lan, C.-Y. (2019). Data science for vibration heteroscedasticity and predictive maintenance of rotary bearings. Energies, 12(5), 801.

Lee, J., Wu, F., Zhao, W., Ghaffari, M., Liao, L., & Siegel, D. (2014). Prognostics and health management design for rotary machinery systems—Reviews, methodology and applications. Mechanical Systems and Signal Processing, 42(1–2), 314–334.

Levin, R. I., & Lieven, N. A. J. (1998). Dynamic finite element model updating using simulated annealing and genetic algorithms. Mechanical Systems and Signal Processing, 12(1), 91–120.

Li, Q., Xu, Q., & Wu, R. (2016). Low-frequency vibration suppression control in a two-mass system by using a torque feed-forward and disturbance torque observer. Journal of Power Electronics, 16(1), 249–258.

Li, Y., Wei, H., & Billings, S. A. (2010). Identification of time-varying systems using multi-wavelet basis functions. IEEE Transactions on Control Systems Technology, 19(3), 656–663.

Liang, J. J., Qin, A. K., Suganthan, P. N., & Baskar, S. (2006). Comprehensive learning particle swarm optimizer for global optimization of multimodal functions. IEEE Transactions on Evolutionary Computation, 10(3), 281–295.

Liu, B., Wang, L., Liu, Y., & Wang, S. (2011). A unified framework for population-based metaheuristics. Annals of Operations Research, 186, 231–262.

Liu, R., Yang, B., Zio, E., & Chen, X. (2018). Artificial intelligence for fault diagnosis of rotating machinery: A review. Mechanical Systems and Signal Processing, 108, 33–47.

Liu, Y. F., Li, J., Zhang, Z. M., Hu, X. H., & Zhang, W. J. (2015). Experimental comparison of five friction models on the same test-bed of the micro stick-slip motion system. Mechanical Sciences, 6(1), 15–28.

Łuczak, D. (2014) “Mathematical model of multi-mass electric drive system with flexible connection,” in 2014 19th International Conference on Methods and Models in Automation and Robotics (MMAR), 2014, pp. 590–595.

Michalewicz, Z., & Schoenauer, M. (1996). Evolutionary algorithms for constrained parameter optimization problems. Evolutionary Computation, 4(1), 1–32.

Morin, A. J. New friction experiments carried out at Metz in 1831–1833 in Proc. French R. Acad. Sci., vol. 4, no. 1, p. 128, 1833.

Mottershead, J. E., & Friswell, M. I. (1993). Model updating in structural dynamics: A survey. Journal of Sound and Vibration, 167(2), 347–375.

Nobari, A. S., Robb, D. A., & Ewins, D. J. (1995). A new approach to modal-based structural dynamic model updating and joint identification. Mechanical Systems and Signal Processing, 9(1), 85–100.

Nowopolski, K. & Wicher, B. (2017) “Parametric identification of electrical drive with complex mechanical structure utilizing particle swarm optimization method,” in 2017 19th European Conference on Power Electronics and Applications (EPE'17 ECCE Europe), 2017, pp. 1–10, 2017.

Orlowska-Kowalska, T., & Szabat, K. (2007). Neural-network application for mechanical variables estimation of a two-mass drive system. IEEE Transactions on Industrial Electronics, 54(3), 1352–1364.

Popovic, M., R., Gorinevsky, D., M., & Goldenberg, A., A. (1995) “Fuzzy logic controller for accurate positioning of direct-drive mechanism using force pulses,” in Proceedings of 1995 IEEE International Conference on Robotics and Automation, vol. 1, pp. 1166–1171.

Reynolds, O. (1886). IV. On the theory of lubrication and its application to Mr. Beauchamp tower’s experiments, including an experimental determination of the viscosity of olive oil. Philos. Trans. r. Soc. London, 177, 157–234.

Robinson, J., & Rahmat-Samii, Y. (2004). Particle swarm optimization in electromagnetics. IEEE Transactions on Antennas and Propagation, 52(2), 397–407.

Shi, Y., Eberhart, R. C. (1999) “Empirical study of particle swarm optimization,” in Proceedings of the 1999 Congress on Evolutionary Computation-CEC99 (Cat. No. 99TH8406), vol. 3, pp. 1945–1950.

Stribeck, R. (1902) Characteristics of plain and roller bearings, Zeit. VDI, vol. 46.

Szabat, K., & Orlowska-Kowalska, T. (2007). Vibration suppression in a two-mass drive system using PI speed controller and additional feedbacks—Comparative study. IEEE Transactions on Industrial Electronics, 54(2), 1193–1206.

Wang, C., Yang, M., Xu, D., Wu, H. (2018) A novel integrated identification method of model structure and parameters for drive system,” in 2018 IEEE 27th International Symposium on Industrial Electronics (ISIE) pp. 101–107.

Wenjing, Z. (2007) “Parameter identification of LuGre friction model in servo system based on improved particle swarm optimization algorithm,” in 2007 Chinese Control Conference, 2007, pp. 135–139.

Zhang, X., & Xu, J. (2017). An extended synchronization method to identify slowly time-varying parameters in nonlinear systems. IEEE Transactions on Signal Processing, 66(2), 438–448.

Acknowledgements

This research was funded by Delta Advanced Technology Research Center, and the Ministry of Science and Technology (MOST110-2221-E-002-163), Taiwan.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hung, YH., Lee, CY., Tsai, CH. et al. Constrained particle swarm optimization for health maintenance in three-mass resonant servo control system with LuGre friction model. Ann Oper Res 311, 131–150 (2022). https://doi.org/10.1007/s10479-021-04255-1

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10479-021-04255-1