Abstract

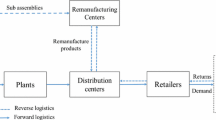

The greenhouse gas emissions due to the energy use in production and distribution in a supply chain are of interest to industries aiming to achieve decarbonization. The industry subjected to carbon regulations require recycling and reusing materials to promote a circular economy through a closed-loop supply chain (CLSC). In this research, we propose a two-stage stochastic model to design the CLSC under a carbon trading scheme in the multi-period planning context by considering the uncertain demands and carbon prices. We also provide a four-step solution procedure with scenario reduction that enables the proposed model to be solved using popular commercial solvers efficiently. This solution makes the proposed model distinguished from the existing models that assume the firms can purchase or sell carbon credits without quantity limitation. The application of the proposed model is demonstrated via simulation-based analysis of the aluminum industry. The results that the proposed stochastic model generates a network with capacity redundancy to cope with the varying customer demands and carbon prices, while only a slight increase in cost and emission is observed compared with the deterministic model. Furthermore, using scenario reduction, the model solved with 80% of the scenarios share the same CLSC network configuration with the model with full scenarios, while the deviation of the total costs is less than 0.53% and the computational burden can be diminished by more than 40%. This research is expected to be useful to solve optimization problems facing large-scale scenarios with known occurrence probabilities aiming for energy conservation and emissions reduction.

Similar content being viewed by others

References

Alizadeh, M., Ma, J., Marufuzzaman, M., & Yu, F. (2019). Sustainable olefin supply chain network design under seasonal feedstock supplies and uncertain carbon tax rate. Journal of Cleaner Production, 222, 280–299.

Alkhayyal, B. A. (2019). Designing an optimization carbon cost network in a reverse supply chain. Production & Manufacturing Research, 7(1), 271–293.

Ambel, C.C. & Earl, T. (2019). How to decarbonize European transport by 2050. European Federation for Transport and Environment AISBL. Brussels, Belgium, 2018 (Available online at: https://www.transportenvironment.org/sites/te/files/publications/2018_11_2050_synthesis_report_transport_decarbonisation.pdf: Accessed last on May 10, 2019).

Aluminum Association (2011). Aluminum: The element of sustainability, A North American Aluminum Industry Sustainability Report (Available online at: http://www.aluminum.org/sites/default/files/Aluminum_The_Element_of_Sustainability.pdf: Accessed last on Dec 10, 2017).

Azaron, A., Venkatadri, U., & Farhang Doost, A. (2021). Designing profitable and responsive supply chains under uncertainty. International Journal of Production Research, 59(1), 213–225.

Baptista, S., Barbosa-Póvoa, A. P., Escudero, L. F., Gomes, M. I., & Pizarro, C. (2019). On risk management of a two-stage stochastic mixed 0–1 model for the closed-loop supply chain design problem. European Journal of Operational Research, 274(1), 91–107.

Boronoos, M., Mousazadeh, M., & Torabi, S. A. (2021). A robust mixed flexible-possibilistic programming approach for multi-objective closed-loop green supply chain network design. Environment, Development and Sustainability, 23(3), 3368–3395.

Dupačová, J., Gröwe-Kuska, N., & Römisch, W. (2003). Scenario reduction in stochastic programming. Mathematical Programming, 95(3), 493–511.

Department for Transport, Great Minster House. (2018). Transport Energy Model (Available online at: https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/739462/transport-energy-model.pdf: Accessed last on July 10, 2021.

Du, S., Qian, J., Liu, T., & Hu, L. (2020). Emission allowance allocation mechanism design: A low-carbon operations perspective. Annals of Operations Research, 291(1), 247–280.

Dvorkin, Y., Wang, Y., Pandzic, H. & Kirschen, D. (2014). Comparison of scenario reduction techniques for the stochastic unit commitment, PES General Meeting| Conference & Exposition, IEEE. IEEE, pp. 1–5.

Elhedhli, S., Gzara, F., & Waltho, C. (2021). Green supply chain design with emission sensitive demand: Second order cone programming formulation and case study. Optimization Letters, 15(1), 231–247.

Fahimnia, B., Jabbarzadeh, A., & Sarkis, J. (2018). Greening versus resilience: A supply chain design perspective. Transportation Research Part e: Logistics and Transportation Review, 119, 129–148.

Fattahi, M., & Govindan, K. (2020). Data-driven rolling horizon approach for dynamic design of supply chain distribution networks under disruption and demand uncertainty. Published online.

Fattahi, M., Govindan, K., & Maihami, R. (2020). Stochastic optimization of disruption-driven supply chain network design with a new resilience metric. International Journal of Production Economics, 230, 107755.

Georgiadis, M. C., Tsiakis, P., Longinidis, P., & Sofioglou, M. K. (2011). Optimal design of supply chain networks under uncertain transient demand variations. Omega, 39(3), 254–272.

Haddadsisakht, A., & Ryan, S. M. (2018). Closed-loop supply chain network design with multiple transportation modes under stochastic demand and uncertain carbon tax. International Journal of Production Economics, 195, 118–131.

Haghjoo, N., Tavakkoli-Moghaddam, R., Shahmoradi-Moghadam, H., & Rahimi, Y. (2020). Reliable blood supply chain network design with facility disruption: A real-world application. Engineering Applications of Artificial Intelligence, 90, 103493.

Hamdan, B., & Diabat, A. (2019). A two-stage multi-echelon stochastic blood supply chain problem. Computers & Operations Research, 101, 130–143.

Hamdan, B., & Diabat, A. (2020). Robust design of blood supply chains under risk of disruptions using Lagrangian relaxation. Transportation Research Part e: Logistics and Transportation Review, 134, 101764.

Heitsch, H., & Römisch, W. (2003). Scenario reduction algorithms in stochastic programming. Computational Optimization and Applications, 24(2), 187–206.

Homayouni, Z., Pishvaee, M.S., Jahani, H. & Ivanov, D. (2021). A robust-heuristic optimization approach to a green supply chain design with consideration of assorted vehicle types and carbon policies under uncertainty. Annals of Operations Research, 1–41.

Jenkins, B. M. (1997). A comment on the optimal sizing of a biomass utilization facility under constant and variable cost scaling. Biomass and Bioenergy, 13(1–2), 1–9.

Kabadurmus, O., & Erdogan, M. S. (2020). Sustainable, multimodal and reliable supply chain design. Annals of Operations Research, 292, 47–70.

Khalifehzadeh, S., & Fakhrzad, M. B. (2019). A Modified Firefly Algorithm for optimizing a multi stage supply chain network with stochastic demand and fuzzy production capacity. Computers & Industrial Engineering, 133, 42–56.

Li, J., Wang, L., & Tan, X. (2020). Sustainable design and optimization of coal supply chain network under different carbon emission policies. Journal of Cleaner Production, 250, 119548.

Liu, Y., Ma, L., & Liu, Y. (2021). A novel robust fuzzy mean-UPM model for green closed-loop supply chain network design under distribution ambiguity. Applied Mathematical Modelling, 92, 99–135.

Manupati, V. K., Jedidah, S. J., Gupta, S., Bhandari, A., & Ramkumar, M. (2019). Optimization of a multi-echelon sustainable production-distribution supply chain system with lead time consideration under carbon emission policies. Computers & Industrial Engineering, 135, 1312–1323.

McKinsey. (2019). Making electric vehicles profitable (Available online at: <https://www.mckinsey.com/~/media/McKinsey/Industries/Automotive%20and%20Assembly/Our%20Insights/Making%20electric%20vehicles%20profitable/Making-electric-vehicles-profitable.pdf: Accessed last on July 30, 2020).

Mohajer Tabrizi, M., Karimi, B., & Mirhassani, S. A. (2016). A novel two-stage stochastic model for supply chain network design under uncertainty. Scientia Iranica, 23(6), 3046–3062.

Mohammed, F., Selim, S. Z., Hassan, A., & Syed, M. N. (2017). Multi-period planning of closed-loop supply chain with carbon policies under uncertainty. Transportation Research Part d: Transport and Environment, 51, 146–172.

Ndjebayi, J. N. (2017). Aluminum Production Costs. (Doctoral Dissertation, Walden University).

Paksoy, T., Bektaş, T., & Özceylan, E. (2011). Operational and environmental performance measures in a multi-product closed-loop supply chain. Transportation Research Part e: Logistics and Transportation Review, 47(4), 532–546.

Pan, F., & Nagi, R. (2010). Robust supply chain design under uncertain demand in agile manufacturing. Computers & Operations Research, 37(4), 668–683.

Pokharel, S., & Liang, Y. (2012). A model to evaluate acquisition price and quantity of used products for remanufacturing. International Journal of Production Economics, 138(1), 170–176.

Römisch, W. (2003). Approximations of stochastic programs. Scenario tree reduction and construction. GAMS Workshop (pp. 1–3). Heidelberg.

Rezaee, A., Dehghanian, F., Fahimnia, B., & Beamon, B. (2017). Green supply chain network design with stochastic demand and carbon price. Annals of Operations Research, 250(2), 463–485.

Salehi, F., Mahootchi, M., & Husseini, S. M. M. (2019). Developing a robust stochastic model for designing a blood supply chain network in a crisis: A possible earthquake in Tehran. Annals of Operations Research, 283(1), 679–703.

Samuel, C. N., Venkatadri, U., Diallo, C., & Khatab, A. (2020). Robust closed-loop supply chain design with presorting, return quality and carbon emission considerations. Journal of Cleaner Production, 247, 119086.

Shu, T., Huang, C., Chen, S., Wang, S., & Lai, K. K. (2018). Trade-Old-for-remanufactured closed-loop supply chains with carbon tax and government subsidies. Sustainability, 10(11), 3935.

Snyder, L. V. (2006). Facility location under uncertainty: A review. IIE Transactions, 38(7), 547–564.

Tolooie, A., Maity, M., & Sinha, A. K. (2020). A two-stage stochastic mixed-integer program for reliable supply chain network design under uncertain disruptions and demand. Computers & Industrial Engineering, 148, 106722.

Urata, T., Yamada, T., Itsubo, N., & Inoue, M. (2017). Global supply chain network design and Asian analysis with material-based carbon emissions and tax. Computers & Industrial Engineering, 113, 779–792.

Valderrama, C. V., Santibanez-González, E., Pimentel, B., Candia-Vejar, A., & Canales-Bustos, L. (2020). Designing an environmental supply chain network in the mining industry to reduce carbon emissions. Journal of Cleaner Production, 254, 119688.

Wang, M., Zhao, L., & Herty, M. (2018). Modelling carbon trading and refrigerated logistics services within a fresh food supply chain under carbon cap-and-trade regulation. International Journal of Production Research, 56(12), 4207–4225.

Wang, Z., Wei, L., Niu, B., Liu, Y., & Bin, G. (2017). Controlling embedded carbon emissions of sectors along the supply chains: A perspective of the power-of-pull approach. Applied Energy, 206, 1544–1551.

Xia, L., Kong, Q., Li, Y. & Qin, J. (2021). Effect of equity holding on a supply chain’s pricing and emission reduction decisions considering information sharing. Annals of operations research, 1–38.

Xu, Z., Elomri, A., Pokharel, S., & Mutlu, F. (2019). The design of green supply chains under carbon policies: A literature review of quantitative models. Sustainability, 11(11), 3094.

Xu, Z., Elomri, A., Pokharel, S., Zhang, Q., Ming, X. G., & Liu, W. (2017). Global reverse supply chain design for solid waste recycling under uncertainties and carbon emission constraint. Waste Management, 64, 358–370.

Xu, Z., Pokharel, S., Elomri, A., & Mutlu, F. (2017b). Emission policies and their analysis for the design of hybrid and dedicated closed-loop supply chains. Journal of Cleaner Production, 142, 4152–4168.

Yavari, M., & Geraeli, M. (2019). Heuristic method for robust optimization model for green closed-loop supply chain network design of perishable goods. Journal of Cleaner Production, 226, 282–305.

Yolmeh, A. & Saif, U. (2020). Closed-loop supply chain network design integrated with assembly and disassembly line balancing under uncertainty: an enhanced decomposition approach. International Journal of Production Research, 1–18.

You, F., & Grossmann, I. E. (2008). Design of responsive supply chains under demand uncertainty. Computers & Chemical Engineering, 32(12), 3090–3111.

Zeballos, L. J., Méndez, C. A., Barbosa-Povoa, A. P., & Novais, A. Q. (2014). Multi-period design and planning of closed-loop supply chains with uncertain supply and demand. Computers & Chemical Engineering, 66, 151–164.

Zhen, L., Huang, L., & Wang, W. (2019). Green and sustainable closed-loop supply chain network design under uncertainty. Journal of Cleaner Production, 227, 1195–1209.

Zhou, X., Zhang, H., Qiu, R., Lv, M., Xiang, C., Long, Y., & Liang, Y. (2019). A two-stage stochastic programming model for the optimal planning of a coal-to-liquids supply chain under demand uncertainty. Journal of Cleaner Production, 228, 10–28.

Acknowledgment

This research was made possible by a NPRP award NPRP No.5-1284-5-198 from the Qatar National Research Fund (a member of The Qatar Foundation). The statements made herein are solely the responsibility of the authors. The partial contribution by Zhitao Xu in this paper was possible due to the funding provided to the author by National Natural Science Foundation of China (Grant No. 71702073), the China Postdoctoral Science Foundation (Grant No. 2018M640483), and the Fundamental Research Funds for the Central Universities (Grant No. NR2020006).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Xu, Z., Pokharel, S. & Elomri, A. An eco-friendly closed-loop supply chain facing demand and carbon price uncertainty. Ann Oper Res 320, 1041–1067 (2023). https://doi.org/10.1007/s10479-021-04499-x

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10479-021-04499-x