Abstract

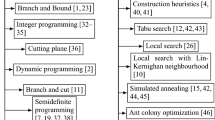

We propose a novel heuristic approach, sequential solution method (SSM), for the efficient solution of Continuous Facility Layout Problems (CFLPs). The proposed SSM approach is compared with exact solution methods as well as Genetic Algorithm (GA) and Simulated Annealing (SA) metaheuristic algorithms. We also improved the metaheuristic approaches based on approximating the facility coordinates with the coordinates of the Center of the Smallest Rectangle (CSR) that covers all facilities in the solution. The proposed SSM approach is a recursive heuristic based on the exact solutions of reduced layout problems. Instead of solving the original CFLP with many variables, SSM first generates subproblems (facility clusters) of smaller sizes using a clustering model and then sequentially solves layout subproblems where non-member facilities locations are constrained. Based on an experimental study, we report that the proposed SSM substantially outperforms exact approaches and meta-heuristic approaches and hence provide an alternative approach for efficiently solving large CFLP instances.

Similar content being viewed by others

References

Abdollahi, P., Aslam, M., & Yazdi, A. A. (2019). Choosing the best facility layout using the combinatorial method of Gray relation analysis and nonlinear programming. Journal of Statistics and Management Systems, 22(6), 1143–1161.

Amorim Lopes, M., Guimarães, L., Alves, J., & Almada Lobo, B. (2020). Improving picking performance at a large retailer warehouse by combining probabilistic simulation, optimization, and discrete-event simulation. International Transactions in Operational Research, 28(2), 687–715.

Balakrishnan, J., & Cheng, C. H. (1998). Dynamic layout algorithms: A state-of the art survey. Omega-International Journal of Management Science, 26(4), 507–521.

Banerjee, P., Montreuil, B., Moodie, C. L., & Kashyap, R. L. (1992). A modeling of interactive facility layout designer reasoning using qualitative patterns. International Journal of Production Research, 30(3), 433–453.

Baykasoglu, A., & Gindy, N. Z. (2001). A simulated annealing algorithm for dynamic layout problem. Computers & Operations Research, 28(14), 1403–1426.

Benjaafar, S., Heragu, S. S., & Irani, S. A. (2002). Next generation factory layouts: Research challenges and recent progress. Interfaces, 32(6), 58–76.

Braglia, M., Zanoni, S., & Zavanella, L. (2005). Layout design in dynamic environments: Analytical issues. International Transactions in Operational Research, 12(1), 1–19.

Chae, J., & Regan, A. C. (2016). Layout design problems with heterogeneous area constraints. Computers & Industrial Engineering, 102, 198–207.

Chae, J., & Regan, A. C. (2020). A mixed integer programming model for a double row layout problem. Computers & Industrial Engineering, 140, 106244.

Chen, X. (2019). An approximate nondominated sorting genetic algorithm to integrate optimization of production scheduling and accurate maintenance based on reliability intervals. Journal of Manufacturing Systems, 54(31), 227–241.

Chwif, L., Barretto, M. R. P., & Moscato, L. A. (1998). A solution to the facility layout problem using simulated annealing. Computers in Industry, 36(1), 125–132.

Covas, M. T., Silva, C. A., & Dias, L. C. (2013). Multicriteria decision analysis for sustainable data centers location. International Transactions in Operational Research, 20(3), 269–299.

Crainic, T. G., Perboli, G., & Tadei, R. (2008). Extreme point based heuristics for three dimensional bin packing. Journal on Computing, 20, 368–384.

Cravo, G. L., & Amaral, A. R. S. (2019). A grasp algorithm for solving large-scale single row facility layout problem. Computers & Operations Research, 106, 49–61.

De Giovanni, L., Massi, G., Pezzella, F., Pfetsch, M. E., Rinaldi, G., & Ventura, P. (2013). A heuristic and an exact method for the gate matrix connection cost minimization problem. International Transactions in Operational Research, 20(5), 627–643.

Ebrahimi, A., Jeon, H. W., Lee, S., & Wang, C. (2020). Minimizing total energy cost and tardiness penalty for a scheduling-layout problem in a flexible job shop system: A comparison of four metaheuristic algorithms. Computers & Industrial Engineering, 141, 106295.

Friedrich, C., Klausnitzer, A., & Lasch, R. (2018). Integrated slicing tree approach for solving the facility layout problem with input and output locations based on contour distance. European Journal of Operational Research, 270(3), 837–851.

Funke, J., Hougardy, S., & Schneider, J. (2016). An exact algorithm for wirelength optimal placements in VLSI design. Integration, 52, 355–366.

García-Hernández, L., Palomo-Romero, J. M., Salas-Morera, L., Arauzo-Azofra, A., & Pierreval, H. (2015). A novel hybrid evolutionary approach for capturing decision maker knowledge into the unequal area facility layout problem. Expert Systems with Applications, 42(10), 4697–4708.

Garcia-Hernandez, L., Pierreval, H., Salas-Moreraa, L., & Arauzo-Azofra, A. (2019). Handling qualitative aspects in Unequal Area Facility Layout Problem: An Interactive Genetic Algorithm. Applied Soft Computing, 13(4), 1718–1727.

Guan, J., & Lin, G. (2016). Hybridizing variable neighborhood search with ant colony optimization for solving the single row facility layout problem. European Journal of Operational Research, 248(3), 899–909.

Hahn, P., & Krarup, J. (2001). A hospital facility layout problem finally solved. Journal of Intelligent Manufacturing, 12(5), 487–496.

Hahn, P. M., Zhu, Y. R., Guignard, M., & Smith., J.M. (2010). Exact solution of emerging quadratic assignment problems. International Transactions in Operational Research, 17(5), 525–552.

Hosseini-Nasab, H., Fereidouni, S., Ghomi, S. M. T. F., & Fakhrzad, M. B. (2018). Classification of facility layout problems: A review study. The International Journal of Advanced Manufacturing Technology, 94(1–4), 957–977.

Hu, G., Chen, Y., Zhou, Z., & Fang, H. (2007). A genetic algorithm for the inter-cell layout and material handling system design. The International Journal of Advanced Manufacturing Technology, 34(11), 1153–1163.

Jeroslow, R. G. (1989). Logic based decision support: Mixed integer model formulation. North-Holland.

Kang, S., & Chae, J. (2017). Harmony search for the layout design of an unequal area facility. Expert Systems with Applications, 79, 269–281.

Kang, S., Kim, M., & Chae, J. (2018). A closed loop based facility layout design using a cuckoo search algorithm. Expert Systems with Applications, 93, 322–335.

Kellegöz, T., Toklu, B., & Wilson, J. (2008). Comparing efficiencies of genetic crossover operators for one machine total weighted tardiness problem. Applied Mathematics and Computation, 199, 590–598.

Keller, B., & Buscher, U. (2015). Single row layout models. European Journal of Operational Research, 8, 1–12.

Kim, J. G., & Kim, Y. D. (2000). Layout planning for facilities with fixed shapes and input and output points. International Journal of Production Research, 38(18), 4635–4653.

Kim, M., & Chae, J. (2019). Monarch butterfly optimization for facility layout design based on a single loop material handling path. Mathematics, 7(2), 154.

Klausnitzer, A., & Lasch, R. (2019). Optimal facility layout and material handling network design. Computers & Operations Research, 103, 237–251.

Koopmans, T. C., & Beckman, M. (1957). Assignment problems and the location of economic activities. Econometrica, 25, 53–76.

Kulturel, K. S., & Konak, A. (2011). A new relaxed flexible bay structure representation and particle swarm optimization for the unequal area facility layout problem. Engineering Optimization, 43(12), 1263–1287.

Kumar, S., & Cheng, J. (2015). A BIM-based automated site layout planning framework for congested construction sites. Automation in Construction, 59, 24–37.

Lacksonen, T. A. (1997). Preprocessing for static and dynamic facility layout problems. International Journal of Production Research, 35(4), 1095–1106.

Langevin, A., Montreuil, B., & Riopel, D. (1994). Spine layout design. International Journal of Production Research, 32(2), 429–442.

Li, X., Wang, Z. X., Chan, F. T. S., & Chung, S. H. (2019). A genetic algorithm for optimizing space utilization in aircraft hangar shop. International Transactions in Operational Research, 26(5), 1655–1675.

Lipowski, A., & Lipowska, D. (2012). Roulette-wheel selection via stochastic acceptance. Physica, 391, 2193–2196.

Liu, J. (2019). Applying multi-objective ant colony optimization algorithm for solving the unequal area facility layout problems. Applied Soft Computing, 74, 167–189.

Lodi, A., Martello, S., & Monaco, M. (2002a). Two dimensional packing problems: A survey. European Journal of Operational Research, 141, 241–252.

Lodi, A., Martello, S., & Vigo, D. (2002b). Recent advances on two dimensional bin packing problems. Discrete Applied Mathematics, 123, 379–396.

Maganha, I., Silva, C., & Ferreira, L. M. D. (2019). The layout design in reconfigurable manufacturing systems: A literature review. The International Journal of Advanced Manufacturing Technology, 105(1), 683–700.

Mak, K. L., Wong, Y. S., & Chan, F. T. S. (1998). A genetic algorithm for facility layout problems. Computer Integrated Manufacturing Systems, 11(1), 113–127.

Meller, R. D., Narayanan, V., & Vance, P. H. (1998). Optimal facility layout design. Operations Research Letters, 23, 117–127.

Mendes, A. B., & Themido, I. H. (2004). Multi-outlet retail site location assessment. International Transactions in Operational Research, 11(1), 1–18.

M’Hallah, R., & Bouziri, A. (2016). Heuristics for the combined cut order planning two dimensional layout problem in the apparel industry. International Transactions in Operational Research, 23(1–2), 321–353.

Montreuil, B., Ouazzani, N., Brotherton, E., Nourelfath, M., (2004b). Location matrix based design methodology for the facility layout problem including aisles and door locations. In Proceedings of the 8th international material handling research colloquium, (pp. 155–182). Graz, Austria.

Montreuil, B., Ouazzani, N., Brotherton, E., Nourelfath, M., (2004a). Coupling zone-based layout optimization, and colony system and domain knowledge. In Proceedings of the 8th international material handling research colloquium, (pp. 303–334). Graz, Austria.

Montreuil, B. (1991). A modelling framework for integrating layout design and flow network design. Material handling’90 (pp. 95–115). Berlin: Springer.

Montreuil, B., Venkatadri, U., & Ratliff, H. D. (1993). Generating a layout from a design skeleton. IIE Transactions, 25(1), 3–15.

Opasanon, S., & Lertsanti, P. (2013). Impact analysis of logistics facility relocation using the analytic hierarchy process (AHP). International Transactions in Operational Research, 20(3), 325–339.

Ou-Yang, C., & Utamima, A. (2013). Hybrid estimation of distribution algorithm for solving single row facility layout problem. Computers & Industrial Engineering, 66(1), 95–103.

Ozyurt, D. B., & Realff, M. J. (1999). Geographic and process information for chemical plant layout problems. AIChE Journal, 45(10), 2161–2174.

Pagès Bernaus, A., Ramalhinho, H., Juan, A. A., & Calvet, L. (2019). Designing ecommerce supply chains: A stochastic facility–location approach. International Transactions in Operational Research, 26(2), 507–528.

Palomo-Romero, M. J., Salas-Morera, L., & Garc´ıa-Herna´ndez, L. (2017). An island model genetic algorithm for unequal area facility layout problems. Expert Systems with Applications, 68, 151–162.

Palubeckis, G. (2017). Single row facility layout using multi-start simulated annealing. Computers & Industrial Engineering, 103, 1–16.

Papageorgiou, L. G., & Rotstein, G. E. (1998). Continuous-domain mathematical models for optimal process plant layout. Industrial & Engineering Chemistry Research, 37, 3631–3639.

Pérez-Gosende, P., Mula, J., & Díaz-Madroñero, M. (2021). Facility layout planning. An extended literature review. International Journal of Production Research, 59(12), 3777–3816.

Ripon, K. S. N., Glette, K., Khan, K. N., Hovin, M., & Torresen, J. (2013). Adaptive variable neighborhood search for solving multi-objective facility layout problems with unequal area facilities. Swarm and Evolutionary Computation, 8, 1–12.

Saraswat, A., Venkatadri, U., & Castillo, I. (2015). A framework for multi-objective facility layout design. Computers & Industrial Engineering, 90, 167–176.

Scalia, G., Micale, R., Giallanza, A., & Marannano, G. (2019). Firefly algorithm based upon slicing structure encoding for unequal facility layout problem. International Journal of Industrial Engineering Computations, 10(3), 349–360.

Schneuwly, P., & Widmer, M. (2003). Layout modeling and construction procedure for the arrangement of exhibition spaces in a fair. International Transactions in Operational Research, 10(4), 311–338.

Scholz, D., Petrick, A., & Domschke, W. (2009). A slicing tree and tabu search based heuristic for the unequal area facility layout problem. European Journal of Operational Research, 197(1), 166–178.

Sherali, H. D., Fraticelli, B. M. P., & Meller, R. D. (2003). Enhanced model formulations for optimal facility layout. Operations Research, 51(4), 692–644.

Tam, K. Y. (1992). A simulated annealing algorithm for allocating space to manufacturing cells. International Journal of Production Research, 30(1), 63–87.

Tate, D. M., & Smith, A. E. (1995). Unequal-area facility layout by genetic search. IIE Transactions, 27(4), 465–472.

Tavakkoli-Moghaddam R., Panahi, H., (2007). Solving a new mathematical model of a closed-loop layout problem with unequal-sized facilities by a genetic algorithm. In Proceedings of the Industrial Engineering and Engineering Management, (pp. 327–331). Singapore.

Turanoğlu, B., & Akkaya, G. (2018). A new hybrid heuristic algorithm based on bacterial foraging optimization for the dynamic facility layout problem. Expert Systems with Applications, 98, 93–104.

Ulutas, B. H., & Kulturel, K. S. (2012). An artificial immune system based algorithm to solve unequal area facility layout problem. Expert Systems with Applications, 39(5), 5384–5395.

Xie, W., & Sahinidis, N. V. (2008). A branch-and-bound algorithm for the continuous facility layout problem. Computers & Chemical Engineering, 32, 1016–1028.

Yang, T., & Peters, B. (1998). Flexible machine layout design for dynamic and uncertain production environments. European Journal of Operational Research, 108, 49–64.

Acknowledgements

We greatly appreciate the editor and anonymous reviewer’s constructive feedback and suggestions which improved the papers presentation clarity and content. This research did not receive any specific grant from funding agencies in the public, commercial or not-for-profit sectors.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Şenol, M.B., Murat, E.A. A sequential solution heuristic for continuous facility layout problems. Ann Oper Res 320, 355–377 (2023). https://doi.org/10.1007/s10479-022-04907-w

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10479-022-04907-w