Abstract

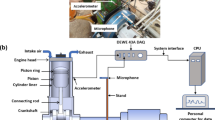

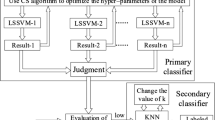

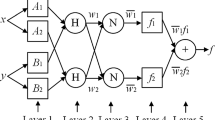

In the case of the fuzzy correlation between variables of faults due to the complex monitoring information of diesel engines, neither Mahalanobis distance (MD) nor Euclidean distance (ED) can effectively diagnose by features, in this paper, a novel Adaptive Dynamic Weighted Hybrid Distance-Taguchi method (ADWHD-T) is presented to diagnose diesel engine faults. The method used Adaptive Dynamic Weighted Hybrid Distance (ADWHD) to fuse data of many sensors into the single system-level performance index. The ADWHD is an adaptive and dynamic weighting of MD and Standardized Euclidean distance (SED). The adaptive weights are adjusted according to the distance scale of MD and SED. The dynamic weight coefficients are calculated by the correlation coefficient of characteristic variables to consider the correlation and independence of characteristic variables. The diagnosis results are derived according to the optimized and adjusted fault threshold of ADWHD defined by 3σ method. In view of the dimension reduction optimization of characteristic variables, combining Taguchi method (T), ADWHD-T provides one systematic method for determining the key parameters of characteristic variables to solve the cost problem of multi-sensor analysis. Aiming at the real-time diagnosis, offline-online modeling and real-time fault diagnosis program based on ADWHD-T are designed. Quoting real-time data from diesel engine benches verifies the effectiveness of the scheme. Compared with MD and MD-T methods, ADWHD-T could promote diagnosis efficiency, enhance classification accuracy and expand its application range in fault diagnosis.

Similar content being viewed by others

References

Chen Z, Wang X, Pei Y, et al. (2015) Experimental investigation of the performance and emissions of diesel engines by a novel emulsified diesel fuel[J]. Energy Convers Manag 95:334–341

Wang X, Cai Y, Li A, et al. (2021) Intelligent fault diagnosis of diesel engine via adaptive VMD-rihaczek distribution and graph regularized bi-directional NMF[j]. Measurement 172:108823

Zhixi S, Xiyue H (2010) Xiaoxiao m. Fault diagnosis of diesel engine based on empirical mode decomposition and support vector machine [J]. Journal of Vibration, Measurement & Diagnosis 1

Wang X, Cai Y, Lin X, Diesel Engine P T (2014) Pump Fault Diagnosis based on the Characteristics of its Fuel Pressure[J]. IERI Procedia 7:84–89

Gu C, Qiao X, Jin Y, et al. (2020) A novel fault diagnosis method for diesel engine based on MVMD and band energy[J] Shock and Vibration

Peng B, Xia H, Lv X, et al. (2021) An intelligent fault diagnosis method for rotating machinery based on data fusion and deep residual neural network[J]. Appl Intell:1–15

Taguchi G, Jugulum R (2002) The Mahalanobis-Taguchi strategy: A pattern technology system[M]. Wiley

Taguchi G, Rajesh J (2000) New trends in multivariate diagnosis[J]. Sankhya: Ind J Stat, Ser B:233–248

Soylemezoglu A, Jagannathan S, Saygin C (2010) Mahalanobis Taguchi system (MTS) as a prognostics tool for rolling element bearing failures[J]. J Manuf Sci Eng 132(5)

Shakya P, Kulkarni M S, Darpe AK (2014) A novel methodology for online detection of bearing health status for naturally progressing defect[J]. J Sound Vib 333(21):5614–5629

Balsamo L, Betti R, Beigi H (2014) A structural health monitoring strategy using cepstral features[J]. J Sound Vib 333(19):4526–4542

Pineyro J, Klempnow A, Lescano V (2000) Effectiveness of new spectral tools in the anomaly detection of rolling element bearings[J]. J Alloys Compound 310(1-2):276–279

Barszcz T, Randall RB (2009) Application of spectral kurtosis for detection of a tooth crack in the planetary gear of a wind turbine[J]. Mech Syst Signal Process 23(4):1352–1365

Yang T, Cheng YT (2010) The use of Mahalanobis-Taguchi System to improve flip-chip bumping height inspection efficiency[J]. Microelectron Reliab 50(3):407–414

Ng F, Harding J A, Glass J (2017) Improving hydraulic excavator performance through in line hydraulic oil contamination monitoring[J]. Mech Syst Signal Process 83:176–193

Hu C, He S, Wang Y (2021) A classification method to detect faults in a rotating machinery based on kernelled support tensor machine and multilinear principal component analysis[J]. Appl Intell 51(4): 2609–2621

Hu C, Wang Y, Gu J (2020) Cross-domain intelligent fault classification of bearings based on tensor-aligned invariant subspace learning and two-dimensional convolutional neural networks[J]. Knowl-Based Syst 209:106214

Jin X, Xu Z, Qiao W (2021) Condition monitoring of wind turbine generators using SCADA data analysis[J]. IEEE Trans Sustain Energy 12(1):202–210

Long B, Xian W, Li M, et al. (2014) Improved diagnostics for the incipient faults in analog circuits using LSSVM based on PSO algorithm with Mahalanobis distance[J]. Neurocomputing 133:237–248

LI Q, YAN C (2012) Research of network traffic anomaly detection technique based on histogram Clustering[J] Netinfo Secur:01

Sun S. (2021) Segmentation-Based Adaptive feature extraction combined with mahalanobis distance classification criterion for heart sound diagnostic System[J]. IEEE Sens J 21(9):11009–11022

Karna S K, Sahai R (2012) An overview on Taguchi method[J]. Int J Eng Math Sci 1(1):1–7

Hogg R V, McKean J, Craig AT (2005) Introduction to mathematical statistics[M]. Pearson Education

Ming-wen XIE (2004) The relation of covariance, correlation coefficient and correlation[J]. Appl Stat Manag:3

Xu K, He D (2015) Further results on estimation of covariance matrix[J]. Stat Probab Lett 101:11–20

Soylemezoglu A, Jagannathan S, Saygin C (2011) Mahalanobis-taguchi system as a multi-sensor based decision making prognostics tool for centrifugal pump failures[J]. IEEE Trans Reliab 60(4):864–878

Ricotta C, Pavoine S, Cerabolini B E L, et al. (2021) A new method for indicator species analysis in the framework of multivariate analysis of variance[J]. J Veg Sci 32(2):e13013

Ding Y, Liang A, Ma K et al (2021) Research on Optimal Strategy of Residential Buildings Energy Based on Standardized Euclidean Distance Measure Similarity Search Method[C]//IOP Conference Series: Earth and Environmental Science. IOP Publish 651(2):022052

Asuero A G, Sayago A, Gonzalez AG (2006) The correlation coefficient: An overview[J]. Crit Rev Anal Chem 36(1):41–59

Platz A, Weckmann U (2019) An automated new pre-selection tool for noisy Magnetotelluric data using the Mahalanobis distance and magnetic field constraints. Geophys J Int 218(3):1853–1872

Yajuan H (2012) Multicollinearity analysis of mahalanobis taguchi system method in multidimensional system Optimization[J]. Ind Eng J 15(2):71

Novak L, Novak D (2101) Estimation of coefficient of variation for structural analysis: The correlation interval approach[J]. Struct Saf 92(10):2021

Chengjiang Q, Mingguang Z, Yinting C, et al. (2014) A quantitative judgement method for safety admittance of facilities in chemical industrial parks based on G1-variation coefficient method[J]. Procedia Eng 84:223–232

Gnedenko B V, Ushakov IA (2018) Theory of probability[M]. Routledge

Chang Z P, Li Y W, Fatima N (2019) A theoretical survey on Mahalanobis-Taguchi system[J]. Measurement 136:501–510

Shojaei P, Haeri S A S, Mohammadi S (2018) Airports evaluation and ranking model using Taguchi loss function, best-worst method and VIKOR technique[J]. J Air Transport Manag 68:4–13

Chan K Y, Rajakaruna N, Engelke U, et al. (2015) Alignment parameter calibration for IMU using the Taguchi method for image deblurring[J]. Measurement 65:207–219

Kivak T (2014) Optimization of surface roughness and flank wear using the Taguchi method in milling of Hadfield steel with PVD and CVD coated inserts[J]. Measurement 50:19–28

Asilturk I, Akku H (2011) Determining the effect of cutting parameters on surface roughness in hard turning using the Taguchi method[J]. Measurement 44(9):1697–1704

Ji D, Hu S, Feng Y, et al. (2021) Geometry optimization of solar thermoelectric generator under different operating conditions via Taguchi method[J]. Energy Convers Manag 238:114158

Han X, Zhang H (2005) Probability theory and mathematical statistics [M]. National Defense Science and Technology University Press, Changsha, pp 190

Probability and statistics group (1977) Department of mathematics and mechanics, Peking University, on the characteristics, creation and uniqueness of orthogonal tables (Continued) [J]. Practice Underst Math (04):28–38

Lin X (2004) Taguchi method and practical technology [M]. Haitian Press, Shenzhen, 66–69

Acknowledgments

Thanks are due to Xingcheng Wang and Zhanhua Wu for assisitance with the experiments. This paper is partly supported by the National Natural Science Foundation of China (61627810), National Key R&D Program of China (2017YFE0128500), Key R&D Program of Guangdong (2020B1111010002), Program for Young Talents of Science and Technology in Universities of Inner Mongolia Autonomous Region (NJYT-17-B34), Inner Mongolia Autonomous Region Natural Science Foundation (2017BS0605), National Science Fund cultivation project of Inner Mongolia University for Nationalities (NMDGP17101), and Inner Mongolia University for Nationalities doctoral research initiation Fund Project (BS416).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, G., Zhou, X., Xu, X. et al. Fault diagnosis of diesel engine information fusion based on adaptive dynamic weighted hybrid distance-taguchi method (ADWHD-T). Appl Intell 52, 10307–10329 (2022). https://doi.org/10.1007/s10489-021-02962-7

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10489-021-02962-7